AR 15 Laser Engraving: Unveiling the Precision and Versatility of Modern Laser Engraving Machines

Laser Engraving Technology and Applications

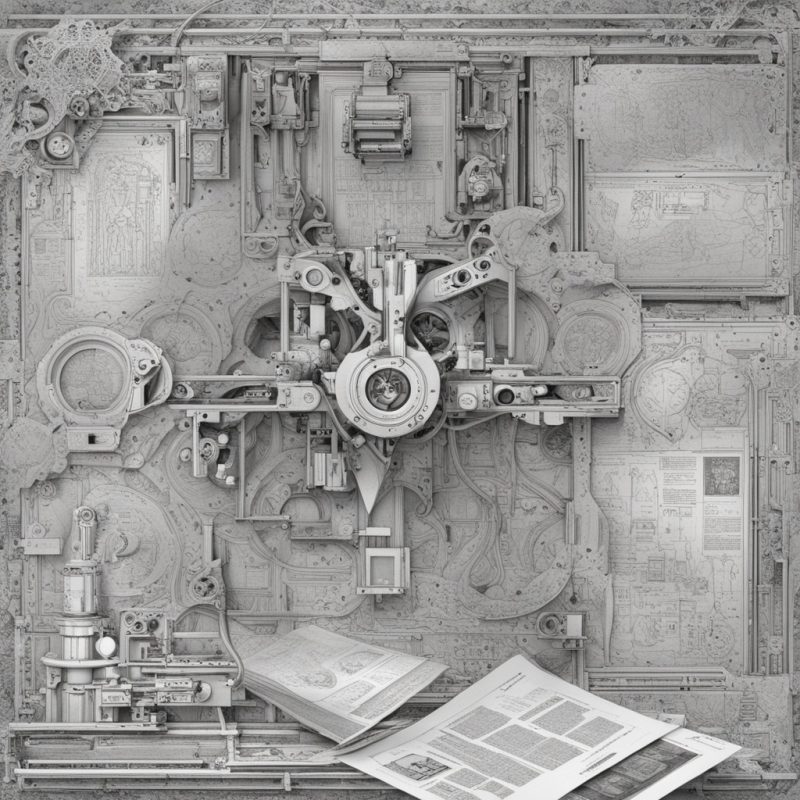

Laser engraving technology has revolutionized the way we personalize and customize a wide range of materials, from metals to plastics and woods. This advanced method employs high-energy laser beams to create intricate designs, text, or images on various surfaces with unparalleled precision. One of the most popular applications of this technology is AR 15 laser engraving, which allows gun enthusiasts and manufacturers to add unique aesthetic touches, serial numbers, or branding to their firearms.

The beauty of laser engraving lies in its ability to produce clean, permanent marks without the need for inks, dyes, or other consumables. This non-contact process ensures that the integrity of the underlying material remains intact, preserving its structural properties and finish. Furthermore, laser engraving machines offer a high degree of flexibility, enabling users to create designs of varying complexity with ease.

Machine Specifications and Features

When it comes to AR 15 laser engraving, the choice of machine is crucial. High-quality laser engraving machines are equipped with advanced features that cater to the specific needs of firearms engraving. Here are some key specifications and features to look for:

- Laser Power: The power of the laser beam determines the depth and speed of engraving. For AR 15s, a machine with a laser power ranging from 30 to 100 watts is typically sufficient for most applications.

- Beam Quality: A focused, high-quality laser beam ensures precise and clean cuts. Look for machines with a beam quality factor (M²) close to 1.

- Workspace Dimensions: The workspace should accommodate the size of the AR 15 or the specific parts you intend to engrave. Machines with larger worktables offer more versatility.

- Software Compatibility: Ensure the machine is compatible with industry-standard design software such as Adobe Illustrator, CorelDRAW, or AutoCAD. This allows for seamless import and manipulation of design files.

- Automation: Features like automatic focusing, material recognition, and job queuing can streamline the engraving process, reducing labor costs and increasing efficiency.

Material Compatibility

AR 15s are primarily made of metals such as aluminum, steel, and titanium. When choosing a laser engraving machine for this application, it’s essential to ensure compatibility with these materials. Here’s an overview of how different metals respond to laser engraving:

- Aluminum: Known for its lightweight and corrosion resistance, aluminum is a popular choice for AR 15 receivers and other components. It engraves well with a clean, matte finish.

- Steel: Requires higher laser power due to its hardness. Engraving steel can produce a contrast between the etched and non-etched areas, adding depth to the design.

- Titanium: This high-strength, low-density metal is often used in critical components like bolt carriers. It engraves with a unique color change, creating a striking visual effect.

In addition to metals, some laser engraving machines can also handle plastics and polymers used in AR 15 grips and stocks. These materials offer different aesthetic possibilities, such as color fills and contrasting textures.

Safety Considerations

Safety is paramount when working with laser engraving machines, especially when handling metal components like those found in AR 15s. Here are some essential safety measures to consider:

- Eye Protection: Always wear laser-safe glasses to protect your eyes from the intense laser beam.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of harmful laser-generated fumes and particles.

- Fire Precautions: Keep flammable materials away from the laser engraving area and have fire extinguishers readily available.

- Machine Guards: Use machine guards and safety interlocks to prevent unauthorized access during operation.

- Training: Provide comprehensive training to all operators on machine operation, safety protocols, and emergency procedures.

Industry Best Practices

Adopting industry best practices can enhance the quality and efficiency of your AR 15 laser engraving projects. Here are some tips to consider:

- Design Preparation: Optimize your design files for laser engraving by using vector graphics and ensuring high resolution.

- Material Preparation: Clean and degrease the metal surfaces to ensure the laser beam can interact with the material evenly.

- Test Runs: Perform test runs on scrap material to fine-tune settings such as laser power, speed, and frequency before engraving the final piece.

- Quality Control: Inspect engraved pieces for defects or inconsistencies and adjust settings accordingly.

- Documentation: Maintain detailed records of each project, including design files, material specifications, and machine settings, for future reference and quality assurance.

Cost-Benefit Analysis

Investing in a high-quality laser engraving machine for AR 15 laser engraving

can offer significant benefits in terms of efficiency, customization options, and brand differentiation. While the initial cost may seem high, a thorough cost-benefit analysis reveals several advantages:

- Cost Savings: Laser engraving eliminates the need for traditional engraving methods like mechanical milling or chemical etching, reducing material waste and labor costs.

- Scalability: Laser engraving machines can handle a range of batch sizes, from one-off prototypes to large-scale production runs.

- Brand Recognition: Unique, high-quality engravings can enhance brand recognition and customer loyalty.

Maintenance Tips

Regular maintenance is crucial for keeping your laser engraving machine in top condition and extending its lifespan. Here are some maintenance tips to follow:

- Daily Cleaning: Clean the lens and mirror surfaces daily to remove dust and debris that can affect beam quality.

- Regular Calibration: Perform regular calibration checks to ensure the machine is operating within specifications.

- Lubrication: Apply lubricant to moving parts as recommended by the manufacturer to reduce wear and tear.

- Filter Replacement:

- Software Updates:

Replace air filters regularly to maintain clean air circulation within the machine.

Keep the machine’s control software up-to-date to benefit from the latest features and bug fixes.

Project Ideas and Tutorials

To inspire your AR 15 laser engraving projects, here are some ideas and tutorials to get you started:

- Custom Serial Numbers: Create unique serial numbers or