The Ultimate Guide to Wood Laser Cutters: Precision, Efficiency, and Creativity

Wood laser cutters have revolutionized the way we craft, design, and manufacture products from wood. These cutting-edge machines combine precision, speed, and versatility to create intricate designs and patterns that were once impossible with traditional tools. Whether you’re a hobbyist, an artist, or a professional in woodworking, understanding how these machines work and their benefits can transform your projects into masterpieces. In this comprehensive guide, we’ll explore everything you need to know about wood laser cutters, including their features, applications, and how to choose the right one for your needs.

What is a Wood Laser Cutter?

A wood laser cutter is a machine that uses a high-powered laser beam to cut or engrave materials, primarily wood. The laser emits a focused beam of light that heats, melts, burns, or vaporizes the material away, leaving behind precise and intricate designs. Unlike traditional cutting methods, which often require physical contact with the material, laser cutting is non-contact, reducing wear and tear on tools and allowing for more delicate and complex patterns.

These machines are ideal for a wide range of applications, from creating custom furniture to crafting decorative items like signs, ornaments, and even musical instruments. The precision and flexibility of wood laser cutters make them a favorite among artists, craftsmen, and manufacturers alike.

How Does a Wood Laser Cutter Work?

To understand how a wood laser cutter operates, let’s break it down into its basic components:

- Laser Source: The core of the machine is the laser source. Most wood laser cutters use a CO₂ laser, which is well-suited for cutting and engraving non-metallic materials like wood, plastic, and leather.

- Focusing Optics: The laser beam is directed through focusing optics to concentrate the light into a pinpoint, creating an intense heat source that can cut or engrave the material.

- Motion System: The machine’s motion system controls the movement of the laser head over the material. This system ensures precise and accurate cuts by following programmed instructions.

- Material Handling: The workpiece is secured on a bed or platform, allowing for smooth cutting operations. Some machines include automatic feed systems for continuous production.

The process begins with designing the desired pattern or image using computer-aided design (CAD) software. This design is then converted into instructions that guide the laser cutter’s movements. As the laser beam moves across the material, it either cuts through it entirely or engraves a design by removing layers of the surface.

Benefits of Using a Wood Laser Cutter

There are numerous advantages to using a wood laser cutter over traditional cutting methods:

- Precision and Accuracy: The laser’s focused beam ensures clean, precise cuts with minimal material waste. This is particularly beneficial for complex designs or patterns that require intricate detailing.

- Versatility: Wood laser cutters can work with various materials beyond wood, including plastic, leather, and acrylic. They are also capable of both cutting and engraving in a single setup.

- Speed and Efficiency: Laser cutting is faster than manual or mechanical methods, making it ideal for high-volume production. The machine can process multiple designs without the need for tool changes.

- Reduced Material Waste: Since the laser cuts with extreme precision, there’s less material waste compared to traditional methods. This not only saves costs but also contributes to a more sustainable manufacturing process.

- Minimal Maintenance: Unlike mechanical tools that require frequent sharpening or replacement, laser cutters have fewer moving parts and therefore require less maintenance.

These benefits make wood laser cutters an indispensable tool for anyone looking to enhance their woodworking projects with precision and creativity.

Applications of Wood Laser Cutters

The applications of wood laser cutters are vast and varied, spanning multiple industries:

- Furniture Making: From intricate table legs to decorative chair backs, laser cutting allows furniture makers to create unique and elegant designs.

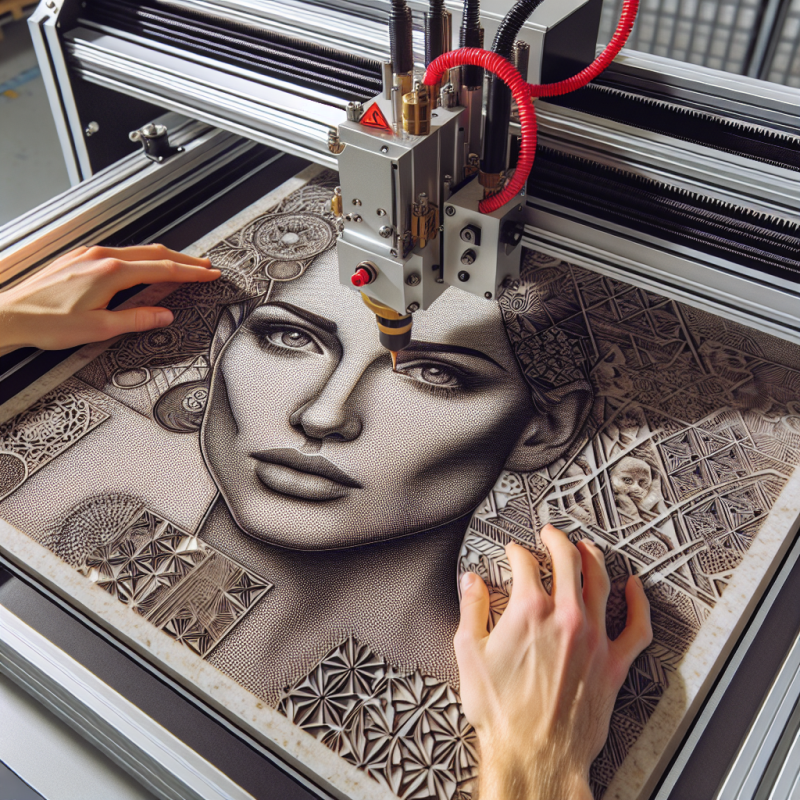

- Art and Decorations: Artists can use wood laser cutters to craft custom signs, wall art, and three-dimensional sculptures with exceptional detail.

- Crafts and Hobbies: Hobbyists can produce personalized items like cutting boards, jewelry boxes, and decorative trinkets with precision and ease.

- Architectural Models: Architects use laser cutters to create scale models of buildings, ensuring accurate details in a fraction of the time.

- Signage and Advertising: Businesses rely on wood laser cutters to produce high-quality signs, banners, and promotional materials with vibrant colors and sharp edges.

The versatility of these machines makes them suitable for both small-scale projects and large-scale industrial applications.

How to Choose the Right Wood Laser Cutter

Selecting the right wood laser cutter depends on several factors, including your budget, project requirements, and desired output quality. Here are some key considerations:

- Laser Power: The power of the laser determines its cutting speed and ability to handle thicker materials. Higher wattage lasers are suitable for industrial use, while lower-wattage machines are ideal for hobbyists or small-scale projects.

- Cutting Speed: Cutting speed is measured in inches per minute (IPM) and varies depending on the material thickness and design complexity. Faster speeds can increase productivity but may compromise precision.

- Bed Size: The size of the machine’s bed determines the maximum workpiece dimensions it can accommodate. Consider your typical project sizes to ensure the bed is large enough for your needs.

- Software Compatibility: Most wood laser cutters come with compatible CAD/CAM software, but ensure that the machine supports industry-standard formats like DXF and SVG for seamless design integration.

- Budget: Wood laser cutters range in price from a few hundred to several thousand dollars. Determine your budget and prioritize features accordingly, focusing on quality and durability rather than just cost.

Taking the time to research and compare different models will help you find a wood laser cutter that best fits your needs and budget.

Top Wood Laser Cutter Models

If you’re in the market for a wood laser cutter, here are some top models worth considering:

- LASER CO₂ Professional Series: Known for their high precision and reliability, these machines are suitable for both hobbyists and professionals.

- Epilog Laser Zing: A compact yet powerful option ideal for small-scale projects and home use.

- Trotec Speedy Series: These industrial-grade lasers offer exceptional cutting speeds and accuracy, making them perfect for large-scale production.

- Universal VLS: A cost-effective choice for beginners, offering good performance for small to medium-sized projects.

Each of these models has its own strengths and weaknesses, so it’s important to evaluate your specific requirements before making a purchase.

Tips for Using a Wood Laser Cutter

To get the most out of your wood laser cutter, follow these tips:

- Use Proper Safety Gear: Always wear safety goggles and ensure the machine is properly enclosed to protect against laser exposure.

- Test Your Design: Before committing to a full-scale project, test your design on scrap material to ensure accuracy and adjust settings as needed.

- Maintain Proper Focus: Regularly check and adjust the laser’s focus to maintain cutting precision. A misaligned beam can lead to poor-quality cuts or damage the machine.

- Keep It Clean: Dust and debris can interfere with the machine’s performance, so clean the bed and optics regularly.

- Experiment with Materials: Don’t be afraid to try different materials beyond wood. Laser cutters are versatile and can work with a variety of substrates, opening up new creative possibilities.

By following these tips, you’ll maximize the machine’s efficiency and extend its lifespan, ensuring high-quality results for years to come.

Frequently Asked Questions About Wood Laser Cutters

1. Can I cut metal with a wood laser cutter?

While some higher-wattage laser cutters can handle metal, most wood laser cutters are optimized for non-metallic materials like wood and plastic. For cutting metal, specialized machines or different types of lasers (such as fiber lasers) are typically required.

2. How much does a wood laser cutter cost?

The cost varies widely depending on the machine’s specifications. Entry-level models start around $500, while industrial-grade lasers can exceed $10,000. It’s important to consider your budget and project needs when selecting a model.

3. What kind of maintenance does a wood laser cutter require?

Regular maintenance includes cleaning the optics, checking the focus alignment, and ensuring proper ventilation to prevent dust buildup. Follow the manufacturer’s guidelines for specific maintenance tasks.

4. Can I engrave with a wood laser cutter?

Yes, many wood laser cutters also have engraving capabilities, allowing you to create detailed designs on materials like wood, acrylic, and leather.

5. Is it safe to use a wood laser cutter at home?

With proper safety precautions, such as using protective eyewear and ensuring good ventilation, yes. However, always follow the manufacturer’s safety instructions to minimize risks.

Conclusion

A wood laser cutter is an invaluable tool for anyone involved in woodworking, crafting, or industrial manufacturing. Its ability to create precise cuts and intricate designs makes it a must-have for both small-scale projects and large-scale production. By understanding the features, selecting the right model, and following proper usage guidelines, you can unlock the full potential of this versatile machine and bring your creative visions to life.

If you’re ready to take your woodworking or crafting skills to the next level, investing in a wood laser cutter could be the perfect choice. With its precision, versatility, and ease of use, it’s no wonder that laser cutting has become such a popular method for creating beautiful and functional pieces. Happy creating!

Exploring the World of Wood Laser Cutters: A Comprehensive Guide

Wood laser cutters have revolutionized woodworking and crafting by offering precise cuts and intricate designs. This guide delves into their features, applications, top models, and essential tips to help you make informed decisions.

—

Key Features and Benefits

- Precision Cutting: Achieve clean, accurate cuts with minimal material waste.

- Engraving Capabilities: Create detailed designs on various materials like wood, acrylic, and leather.

- Versatility: Ideal for both small-scale projects and industrial applications.

- Speed and Efficiency: Save time by producing high-quality results quickly.

—

**Applications**

Wood laser cutters are versatile and can be used in:

- Furniture Making: For intricate designs and joints.

- Decorative Art: Creating wall art, cutting stencils, or custom patterns.

- Signage Production: Designing professional signs with sharp edges and vibrant colors.

- Industrial Manufacturing: Prototyping and producing parts for machinery.

—

**How to Choose the Right Wood Laser Cutter**

Consider these factors when selecting a wood laser cutter:

- Laser Power (Wattage): Higher wattage suits thicker materials; lower wattage is ideal for thinner projects.

- Cutting Speed: Measured in inches per minute, balancing speed with precision.

- Bed Size: Ensure it accommodates your typical project sizes.

- Software Compatibility: Check support for standard formats like DXF and SVG.

- Budget: Determine your budget to prioritize quality and durability.

—

**Top Wood Laser Cutter Models**

- LASER CO₂ Professional Series: High precision, suitable for both hobbyists and professionals.

- Epilog Laser Zing: Compact and powerful for small-scale projects and home use.

- Trotec Speedy Series: Industrial-grade lasers with exceptional cutting speeds and accuracy.

- Universal VLS: Cost-effective for beginners, offering good performance for small to medium projects.

—

**Tips for Using a Wood Laser Cutter**

- Safety First: Wear safety goggles and ensure proper enclosure to protect against laser exposure.

- Test Designs: Use scrap material to test designs before full-scale production.

- Maintain Focus: Regularly check and adjust the laser’s focus for precision.

- Cleanliness: Dust and debris can interfere with performance; clean regularly.

- Experiment: Try different materials beyond wood to unlock creative possibilities.

—

**Frequently Asked Questions**

- Can I cut metal? Most are optimized for non-metallic materials; specialized machines are better for metal.

- Cost Range: Entry-level models start around $500, with industrial-grade lasers exceeding $10,000.

- Maintenance Needs: Regularly clean optics and ensure proper ventilation.

- Engraving Capabilities: Yes, many models allow engraving on various materials.

- Home Safety: Safe with proper precautions like protective eyewear and good ventilation.

—

**Conclusion**

A wood laser cutter is an invaluable tool for woodworking, crafting, and industrial manufacturing. With its precision, versatility, and ease of use, it’s a must-have for anyone looking to elevate their creative projects. Whether you’re a hobbyist or a professional, investing in a wood laser cutter can unlock new levels of creativity and efficiency.

—

Happy Creating!