The Art of Laser Engraving Metal: Precision, Beauty, and Durability

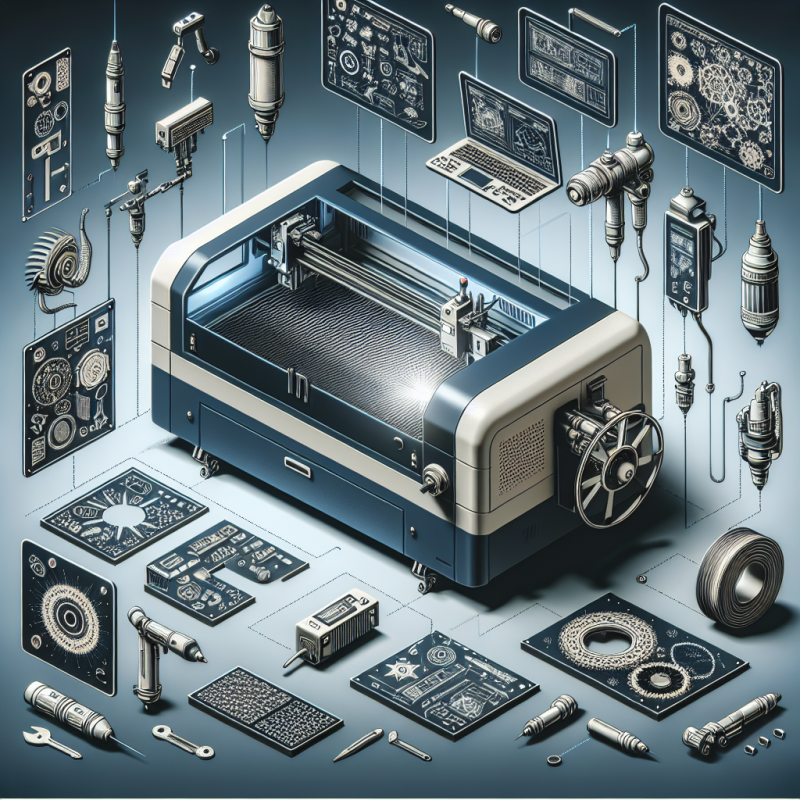

Laser engraving metal has become one of the most popular methods for creating intricate designs, patterns, and text on metallic surfaces. This innovative technique combines precision, durability, and aesthetic appeal, making it a favorite among artists, manufacturers, and hobbyists alike. Whether you’re looking to create custom jewelry, industrial parts, or decorative items, laser engraving metal offers unparalleled flexibility and quality. In this article, we’ll explore the benefits of laser engraving metal, its applications, and how you can get started with this incredible technology.

The Benefits of Laser Engraving Metal

Laser engraving metal offers numerous advantages over traditional methods like mechanical engraving or acid etching. Here are some of the key benefits:

- Precision and Detail: Lasers can create incredibly fine details, allowing for intricate designs that would be impossible with other methods.

- Durability: Laser engravings are permanent and resistant to wear, ensuring your designs last a lifetime.

- Versatility: Laser engraving can be used on various types of metal, including steel, stainless steel, titanium, aluminum, brass, and copper.

- Speed: Compared to manual engraving, laser engraving is much faster, making it ideal for large-scale production.

- Eco-Friendly: Laser engraving produces minimal waste and doesn’t require harmful chemicals, making it an environmentally friendly option.

- Cost-Effective: Once the initial investment in equipment is made, laser engraving can be more cost-effective than traditional methods, especially for high-volume projects.

Applications of Laser Engraving Metal

Laser engraving metal has a wide range of applications across various industries. Here are some of the most common uses:

- Jewelry Making: Custom engravings on rings, bracelets, necklaces, and other jewelry pieces.

- Industrial Parts: Engraving serial numbers, barcodes, or logos on metal components for identification purposes.

- Decorative Items: Creating artistic designs on metal plates, signs, and sculptures.

- Custom Products: Personalized engravings on items like watches, knives, firearms, and tools.

- Promotional Gifts: Engraving company logos or custom messages on metal items such as pens, keychains, and trophies.

- Artistic Creations: Using laser engraving to create unique works of art on metal surfaces.

Materials Compatible with Laser Engraving Metal

Not all metals are suitable for laser engraving. However, there are several types that work exceptionally well with this technique:

- Steel: Ideal for deep engravings and industrial applications.

- Stainless Steel: Popular for its resistance to corrosion and ability to hold fine details.

- Titanium: A lightweight yet durable option for jewelry and medical devices.

- Aluminum: Great for decorative purposes due to its shiny finish and ease of engraving.

- Brass: Offers a warm, golden color and is commonly used for signage and trophies.

- Copper: Known for its reddish hue and ability to hold intricate designs.

Getting Started with Laser Engraving Metal

If you’re interested in laser engraving metal, there are a few things you need to know before getting started:

- Equipment: You’ll need a high-quality laser engraver. The best option for most users is the , which offers precision and versatility for both small and large projects.

- Design Software: Use design software like Adobe Illustrator or CorelDRAW to create your engravings. Many laser engravers also come with compatible software that makes the process even easier.

- Material Preparation: Ensure your metal surfaces are clean and free of oils, grease, or rust before engraving. This will help achieve the best results.

- Engraving Settings: Adjust your laser settings based on the type of metal you’re working with. Factors like power, speed, and focus distance can significantly impact the quality of your engravings.

Tips for Achieving Perfect Engravings

To get the most out of your laser engraving metal projects, keep these tips in mind:

- Test First: Always test your settings on a scrap piece of metal before starting your final project. This will help you avoid costly mistakes.

- Use the Right Lens: The lens on your laser engraver plays a crucial role in focusing the laser beam. Make sure to use the correct lens for your specific needs.

- Consider Depth: Depending on the thickness of your metal, you may need to adjust the number of passes or layers to achieve the desired depth.

- Cooling: Some metals require cooling during engraving to prevent warping or discoloration. Use compressed air or a water-based cooling system if necessary.

The Future of Laser Engraving Metal

As technology continues to advance, laser engraving metal is becoming more accessible and affordable for individuals and businesses alike. With its ability to create detailed, durable, and custom designs, it’s no wonder this technique is growing in popularity across various industries.

If you’re ready to dive into the world of laser engraving metal, consider investing in a reliable system like the DREMEL DLC 40 Laser Crafting System. This versatile tool will allow you to explore your creative potential and bring your ideas to life with precision and ease.

So why wait? Start your journey into laser engraving metal today and unlock a world of possibilities!