The Ultimate Guide to Engraver Cutter Lasers

Introduction

In the ever-evolving world of technology, precision tools have become indispensable for both professionals and hobbyists. Among these tools, the engraver cutter laser stands out as a revolutionary device that combines cutting-edge technology with unparalleled accuracy. Whether you’re working on intricate designs, custom engravings, or industrial applications, this tool has become a cornerstone in modern craftsmanship. But what exactly is an engraver cutter laser? How does it work? And why is it becoming so popular? Let’s dive into the details and explore everything you need to know about this fascinating technology.

Understanding Engraver Cutter Lasers

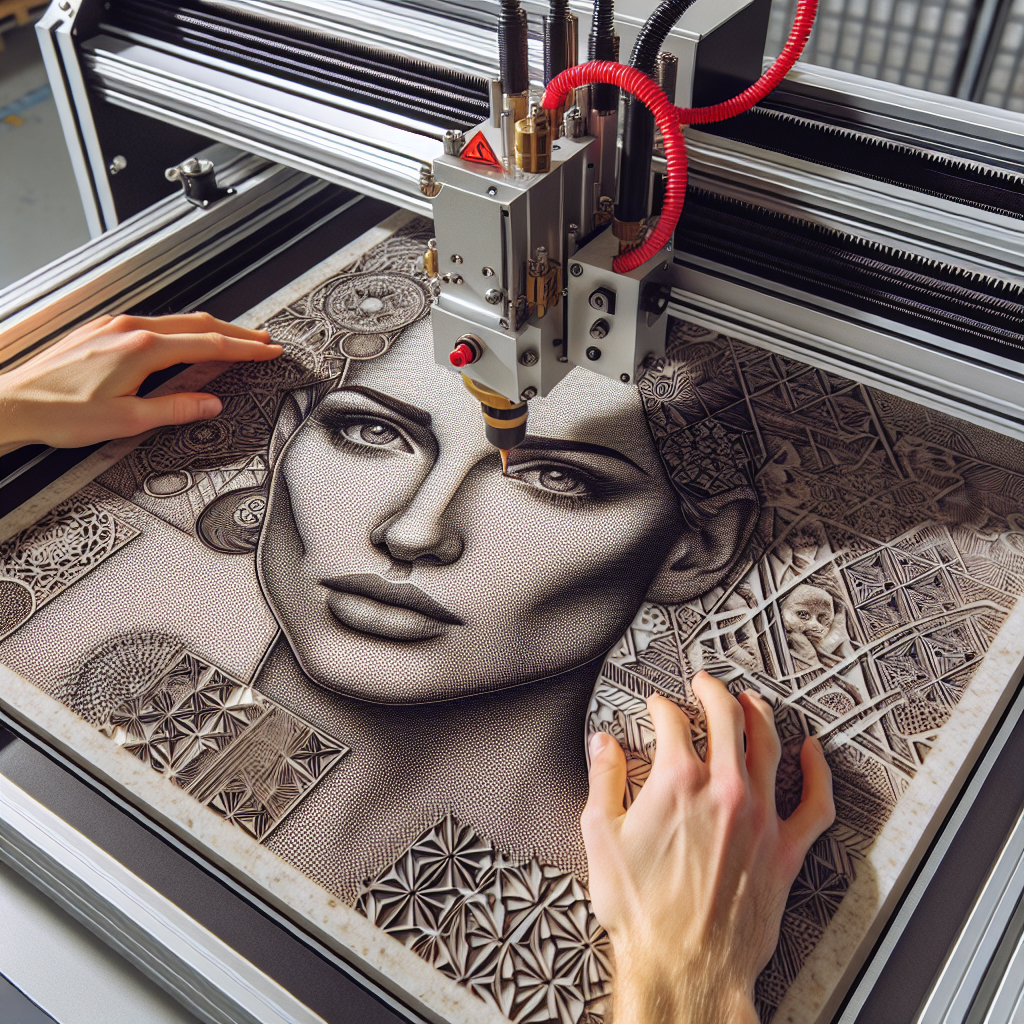

An engraver cutter laser is a precision tool designed for cutting, engraving, and marking materials with exceptional accuracy. Unlike traditional engraving tools, which rely on mechanical contact, laser engravers use light beams to create precise and intricate designs. This makes them ideal for a wide range of applications, from jewelry making to industrial manufacturing.

The core of an engraver cutter laser lies in its ability to focus high-energy light into a narrow beam. This beam can melt, burn, or vaporize the material it comes into contact with, leaving behind a precisely engraved design. The precision of these machines is often measured in micrometers, making them suitable for even the most delicate projects.

One of the key advantages of an engraver cutter laser is its versatility. It can work with various materials, including wood, metal, plastic, glass, and leather. This flexibility makes it a favorite among artists, craftsmen, and manufacturers who need to work with multiple materials in a single project.

The Benefits of Using an Engraver Cutter Laser

There are numerous reasons why an engraver cutter laser has become a must-have tool for many professionals. Here are some of the most significant benefits:

- High Precision: The ability to create intricate designs with micrometer-level accuracy is unmatched by traditional engraving tools.

- Versatility: It can work with a wide range of materials, making it suitable for various industries and projects.

- Speed: Laser engraving is faster than manual engraving, saving time and increasing productivity.

- Durability: The lack of mechanical contact reduces wear and tear, ensuring longer tool life.

- Clean Finish: Unlike traditional methods that may leave behind burrs or rough edges, laser engraving produces a smooth, polished finish.

If you’re wondering, “What materials can you work with using an engraver cutter laser?” the answer is almost anything! From delicate plastics to tough metals, this tool handles it all with ease. This versatility makes it a go-to choice for industries like jewelry making, automotive manufacturing, and even medical device production.

Applications of Engraver Cutter Lasers

The applications of an engraver cutter laser are as diverse as the materials it can work with. Here are some of the most common uses:

- Jewelry Making: Engraving intricate designs on metals like gold, silver, and platinum.

- Custom Engravings: Adding personalized text or logos to items like name tags, plaques, and trophies.

- Industrial Manufacturing: Marking serial numbers, barcodes, and other identification details on products.

- Crafts and Artwork: Creating detailed patterns and illustrations on wood, glass, and leather.

- Fabric Cutting: Precision cutting of fabric for clothing and upholstery industries.

The ability to work with such a wide range of materials makes the engraver cutter laser an invaluable tool in both small-scale craftsmanship and large-scale industrial production. Whether you’re working on a one-off project or producing thousands of identical items, this machine delivers consistent quality and precision every time.

Choosing the Right Engraver Cutter Laser

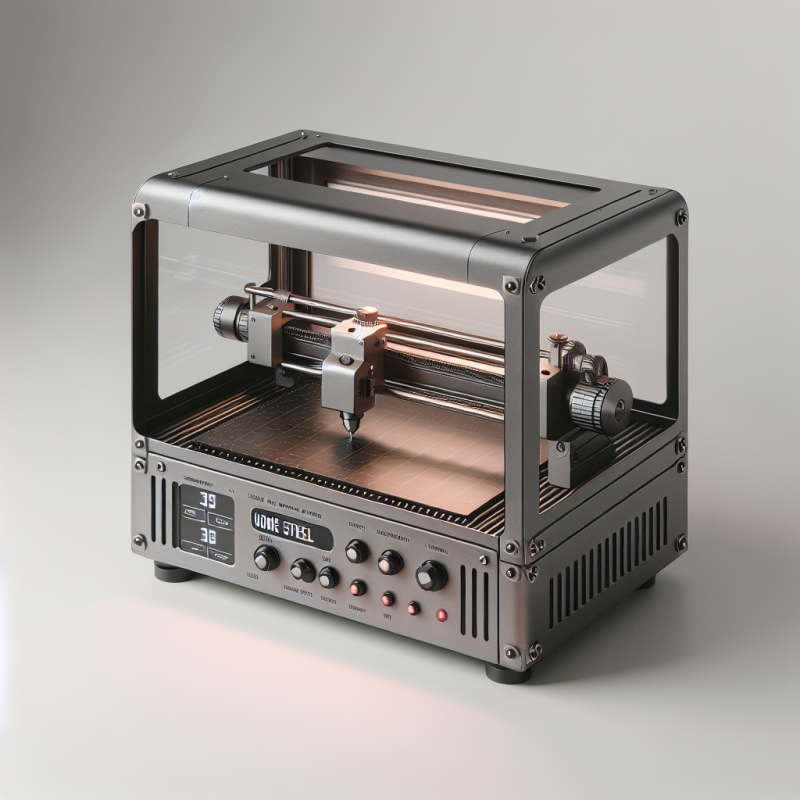

With so many options available in the market, selecting the right engraver cutter laser can be a daunting task. Here are some factors to consider when making your choice:

- Material Compatibility: Determine which materials you’ll primarily work with and ensure the laser is compatible with them.

- Precision Requirements: Consider the level of detail needed for your projects. Higher precision lasers are ideal for intricate designs.

- Budget: Decide on your budget and look for models that offer the best features within your price range.

- Size and Portability: If you need a machine for on-the-go projects, consider compact and portable options.

If you’re still unsure about which model to choose, you might ask yourself, “Where can I find the best engraver cutter laser?” The answer is simple: look for reputable brands that offer high-quality machines with a proven track record of performance. Many online retailers and specialized tool stores carry these devices, so don’t hesitate to do some research before making your purchase.

Maintenance and Safety Tips

Like any precision tool, an engraver cutter laser requires proper care and maintenance to ensure optimal performance. Here are some tips to keep your machine running smoothly:

- Regular Cleaning: Clean the lens and working area after each use to prevent dust and debris from affecting precision.

- Firmware Updates: Keep your machine’s firmware up-to-date to ensure it operates at peak efficiency.

- Safety First: Always wear protective eyewear when operating the laser, as the light beam can be harmful if not handled properly.

By following these simple maintenance and safety tips, you can extend the life of your machine and ensure it continues to deliver high-quality results for years to come.

Frequently Asked Questions

If you’re new to using an engraver cutter laser, you might have some questions. Here are answers to some of the most common ones:

- How easy is it to learn how to use a laser engraver? Most models come with intuitive software and user guides, making them accessible even for beginners.

- Can I engrave on curved surfaces? Yes, many modern laser engravers are equipped with features that allow for engraving on curved or uneven surfaces.

- Is it safe to use a laser engraver at home? Absolutely! Just follow the safety guidelines provided by the manufacturer and always wear protective eyewear.

If you’re still unsure about anything, don’t hesitate to reach out to customer support or consult online forums where experienced users often share tips and advice.

Conclusion

An engraver cutter laser is a powerful tool that has transformed the way we approach engraving and cutting projects. Its precision, versatility, and ease of use make it an indispensable addition to any workshop or manufacturing facility. Whether you’re a seasoned professional or just starting out, investing in one of these machines can elevate your craft to new heights.

If you’re ready to take the plunge and purchase your own engraver cutter laser, don’t forget to consider your specific needs and budget. With the right machine by your side, you’ll be able to tackle even the most challenging projects with confidence and precision.