The Ultimate Guide to Engraver Cutter Laser

Laser engraving technology has revolutionized the way we create intricate designs and personalized items. Whether you’re an artist, a hobbyist, or a business owner, an engraver cutter laser offers unparalleled precision and versatility. In this comprehensive guide, we’ll explore what an engraver cutter laser is, its applications, benefits, and how to choose the right one for your needs.

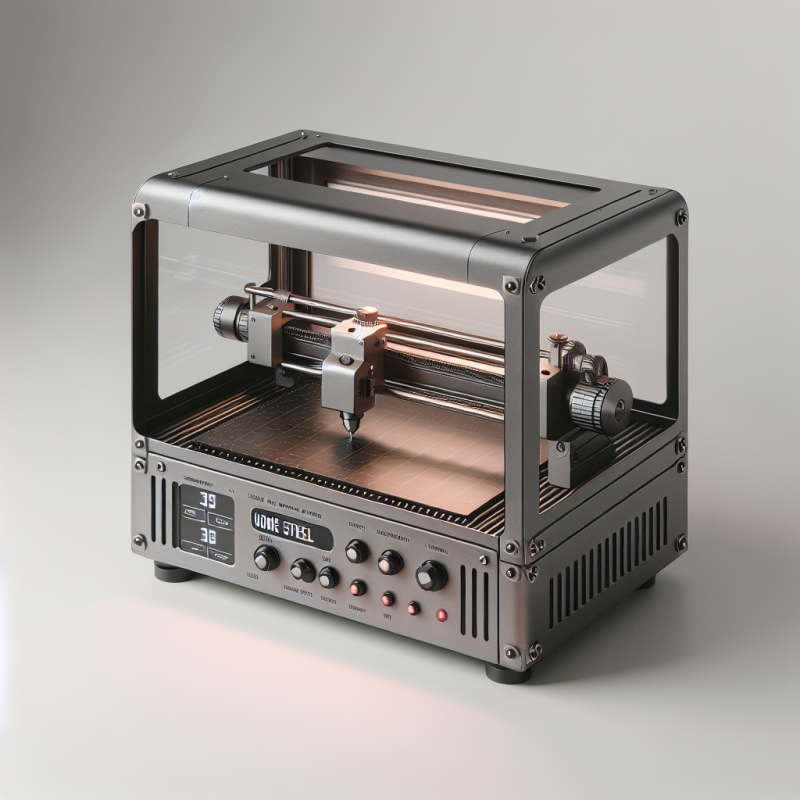

What Is an Engraver Cutter Laser?

An engraver cutter laser is a machine that uses focused laser light to etch or cut materials with high precision. Unlike traditional engraving tools, which rely on mechanical cutting, laser engravers use heat and light to create designs. This makes them ideal for working with various materials, including wood, metal, plastic, glass, and more.

The process involves directing a laser beam through mirrors and lenses to focus it onto the material’s surface. The intense heat generated by the laser vaporizes or melts the material, creating precise engravings or cuts. This method is not only faster but also produces cleaner results compared to traditional engraving methods.

Applications of an Engraver Cutter Laser

One of the most appealing aspects of an engraver cutter laser is its versatility. It can be used in a wide range of industries and projects:

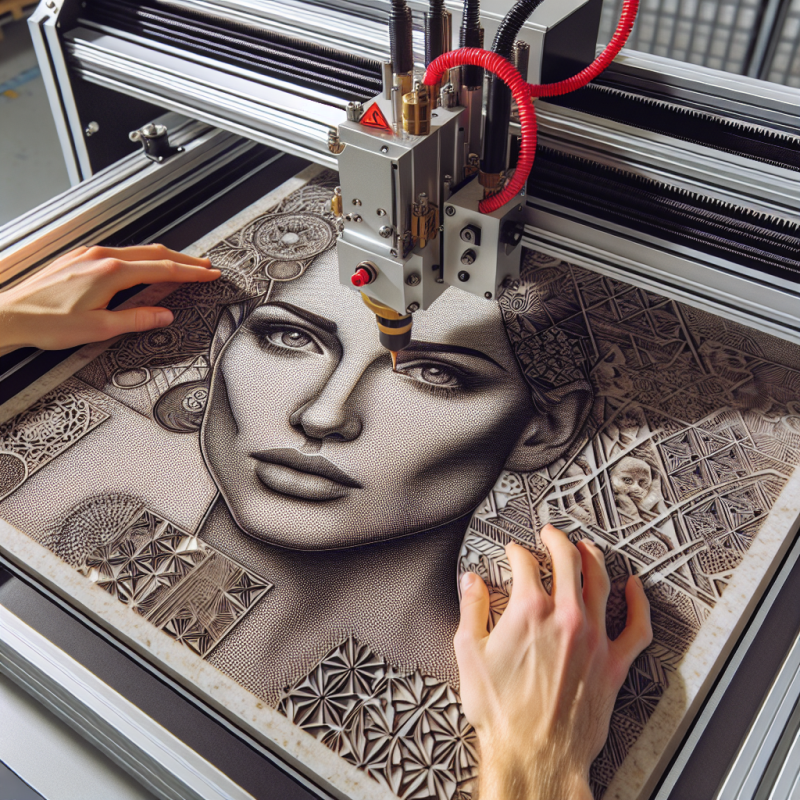

- Custom Products: Create personalized jewelry, name tags, awards, and plaques with intricate designs.

- Artistic Creations: Produce detailed artwork on various materials, including wood, metal, and glass.

- Industrial Uses: Engrave serial numbers, barcodes, or logos onto products for identification and branding purposes.

- Hobbyist Projects: Hobbyists can use laser engravers to create custom DIY projects, such as engraved wooden signs or decorative items.

Benefits of Using an Engraver Cutter Laser

Switching to an engraver cutter laser offers numerous advantages over traditional engraving methods:

- Precision and Accuracy: The laser beam ensures clean, precise cuts and engravings, even on complex designs.

- Speed: Laser engraving is significantly faster than manual engraving, making it ideal for large-scale projects.

- Versatility: Works with a wide range of materials, allowing for creative freedom in design.

- Durability: The machine’s components are designed to last, reducing maintenance and replacement costs over time.

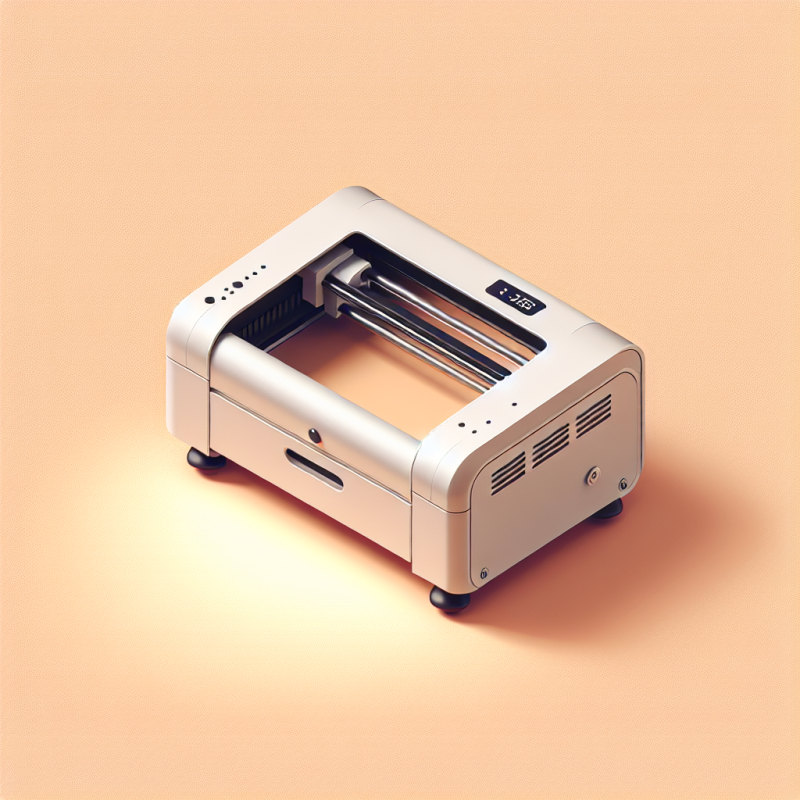

How to Choose the Right Engraver Cutter Laser

Selecting the best engraver cutter laser for your needs requires careful consideration of several factors:

- Material Compatibility: Ensure the laser is compatible with the materials you plan to work with.

- Power Output: Higher wattage lasers are better suited for cutting through thicker or harder materials.

- Software Compatibility: Look for machines that support popular design software like CorelDRAW or Adobe Illustrator.

- Budget: Determine your budget and compare features across different models to find the best value.

Question: What industries benefit most from using an engraver cutter laser?

Answer: Industries such as jewelry making, custom product manufacturing, and artistic creation benefit significantly due to the precision and versatility of laser engraving.

Key Features of a High-Quality Engraver Cutter Laser

When investing in an engraver cutter laser, it’s essential to look for machines with the following features:

- High-Power Laser Tube: Ensures strong, consistent performance for cutting and engraving.

- Adjustable Focus Lens: Allows precise control over the laser beam for different materials.

- User-Friendly Interface: Easy-to-use controls and software for seamless operation.

- Safety Features: Includes safety guards and emergency stop mechanisms to protect users during operation.

Maintenance Tips for Your Engraver Cutter Laser

To ensure your engraver cutter laser performs optimally, follow these maintenance tips:

- Regularly clean the machine’s lens and mirrors to prevent dust buildup, which can reduce performance.

- Check and replace the laser tube as needed to maintain optimal power output.

- Store the machine in a dry, dust-free environment when not in use.

- Follow the manufacturer’s guidelines for routine maintenance and servicing.

Frequently Asked Questions About Engraver Cutter Lasers

Question: Can an engraver cutter laser work on all materials?

Answer: While most lasers can handle common materials like wood, metal, and plastic, some specialized materials may require specific settings or adjustments. Always test the machine on a small sample before starting a full project.

Question: Is it easy to learn how to use an engraver cutter laser?

Answer: With proper training and user-friendly software, even beginners can master the basics of using an engraver cutter laser in no time.

Final Thoughts

An engraver cutter laser is an invaluable tool for anyone looking to create precise, high-quality engravings or cuts. Its versatility, precision, and efficiency make it a worthwhile investment for both professionals and hobbyists. By considering your specific needs and choosing the right machine, you can unlock new creative possibilities and elevate your projects to the next level.

If you’re ready to take your engraving game to the next level, explore our range of high-quality engraver cutter lasers today!