Mastering Laser Cutting Wood: A Comprehensive Guide

Laser cutting wood has revolutionized the way we approach woodworking projects. Whether you’re a hobbyist or a professional craftsman, this technology offers precision, efficiency, and creativity that traditional methods simply can’t match. In this article, we’ll dive into everything you need to know about laser cutting wood, from the basics of how it works to its applications and benefits. We’ll also explore how tools like the machine can transform your woodworking projects.

What Is Laser Cutting Wood?

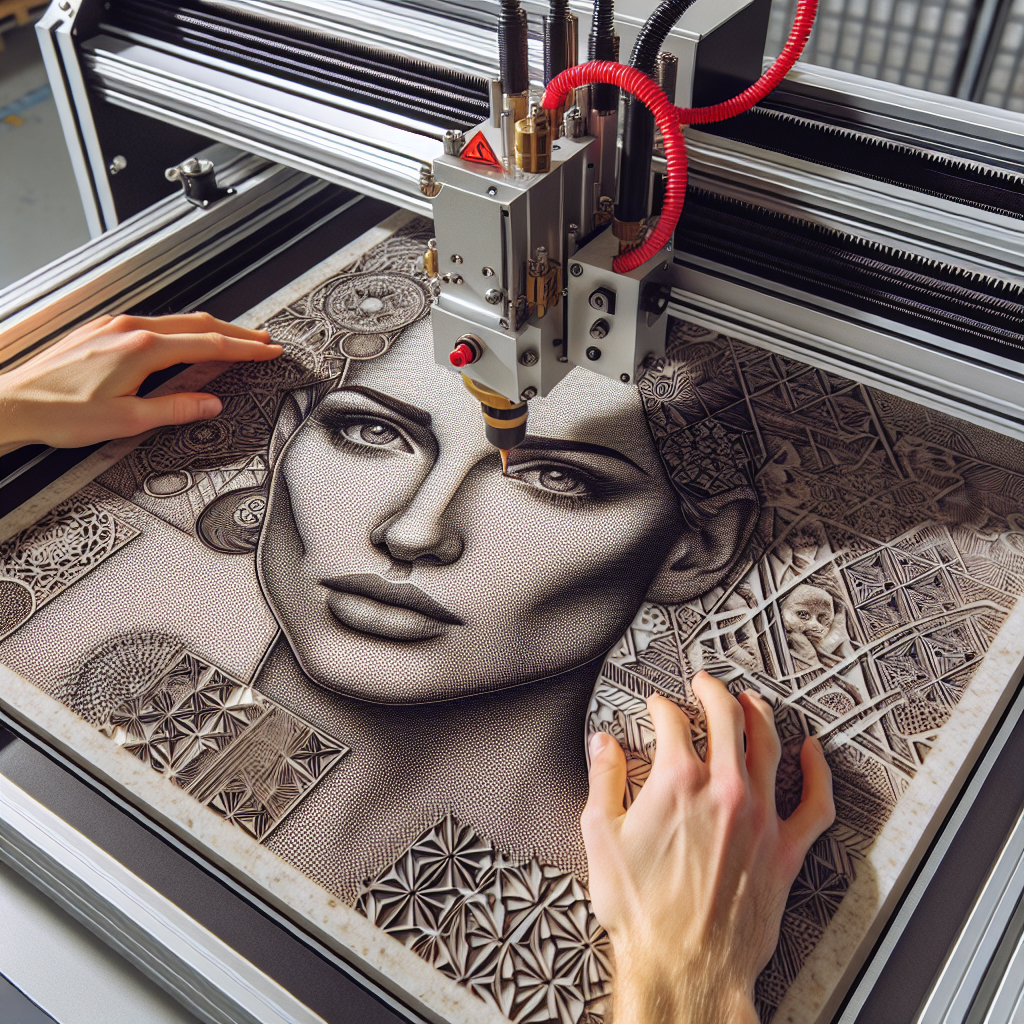

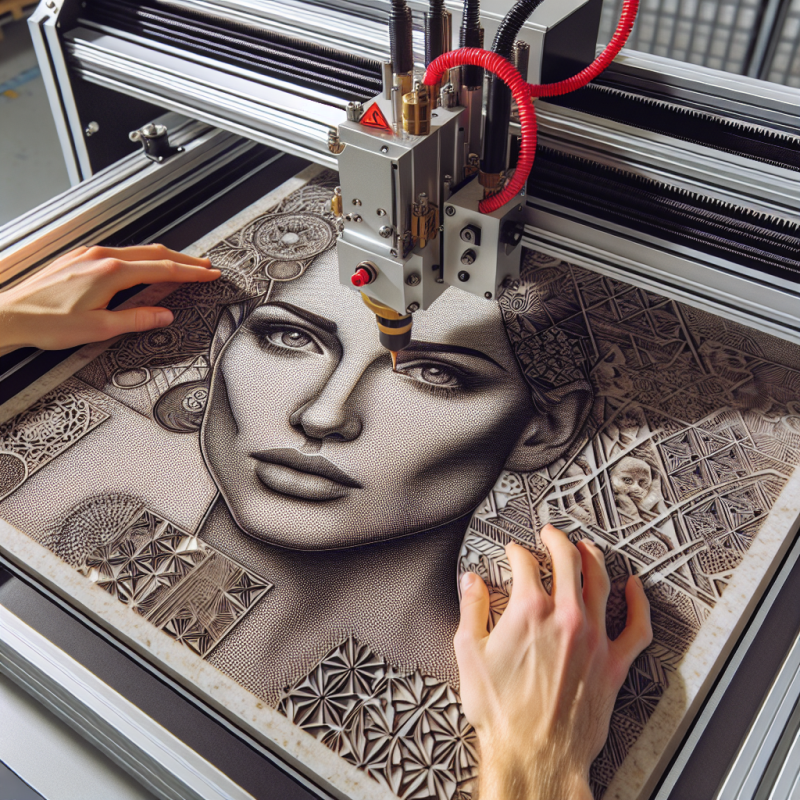

Laser cutting wood is a process that uses a focused laser beam to cut, engrave, or etch designs onto wooden surfaces. Unlike traditional cutting methods that rely on physical tools like saws or drills, laser cutting uses heat generated by the laser to vaporize or burn away material. This results in clean, precise cuts and intricate designs that are difficult to achieve manually. The process is not only faster but also minimizes waste, making it an ideal choice for both small-scale and large-scale woodworking projects.

One of the key advantages of laser cutting wood is its versatility. It can handle a wide range of materials, from thin plywood to thick hardwoods, and can create everything from simple shapes to complex patterns. Whether you’re crafting custom furniture, decorative items, or signage, laser cutting offers endless possibilities.

The Benefits of Laser Cutting Wood

Laser cutting wood has numerous advantages over traditional woodworking methods. Here are some of the top benefits:

- Precision and Accuracy: Lasers can cut with incredible precision, allowing for intricate designs and tight tolerances that are difficult to achieve manually.

- Speed and Efficiency: Laser cutting machines work quickly, reducing the time it takes to complete projects compared to traditional methods.

- Versatility: Lasers can handle a wide range of materials and design complexities, making them suitable for various woodworking applications.

- Minimal Waste: The laser beam only removes the material that is necessary, resulting in less waste compared to methods like CNC routing or manual cutting.

- Non-Contact Process: Since there’s no physical contact between the tool and the wood, there’s no risk of damaging the material during the cutting process.

If you’re wondering how laser cutting can benefit your woodworking projects, the answer lies in its ability to combine precision with creativity. With the right machine, such as the tool mentioned earlier, you can unlock new levels of design freedom and efficiency.

How Does Laser Cutting Wood Work?

To understand how laser cutting wood works, let’s break it down into simple steps:

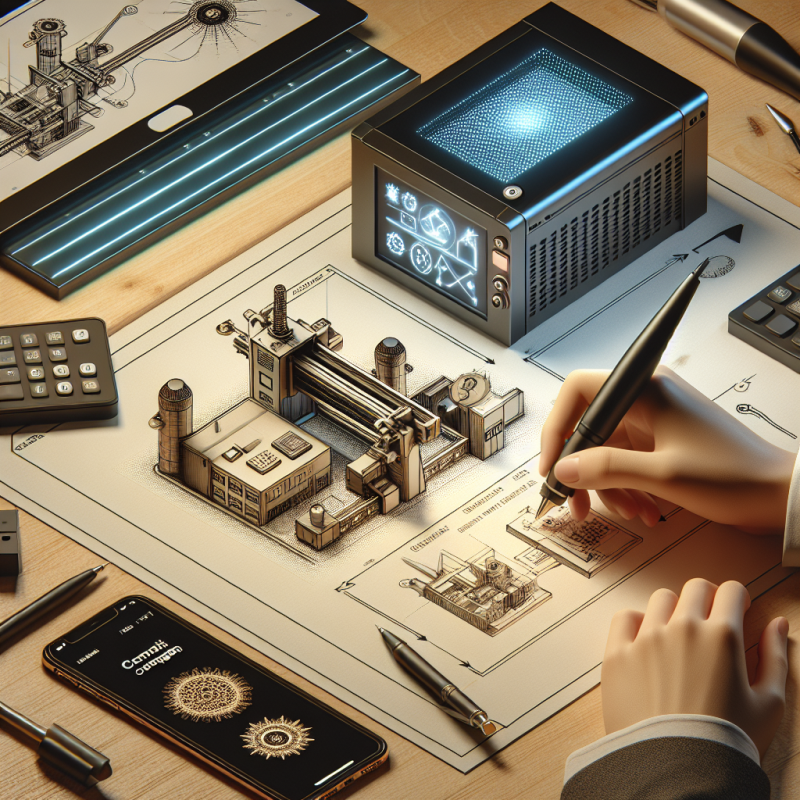

- Design Creation: The first step is to create a digital design of the project you want to cut. This can be done using computer-aided design (CAD) software or graphic design tools.

- Laser Beam Generation: The laser machine generates a high-powered laser beam, typically made from CO2 or fiber lasers, which is focused onto the wood surface.

- Cutting or Engraving: The laser beam heats and vaporizes the wood at specific points, creating cuts or engravings according to the digital design. The intensity and speed of the laser can be adjusted depending on the desired outcome.

- Material Removal: As the laser moves across the wood, it removes material layer by layer until the final design is achieved.

The process is highly controlled and automated, ensuring consistency and accuracy in every cut. This makes it an excellent choice for both small-scale and large-scale production runs. If you’re curious about how to get started with laser cutting wood, investing in a reliable machine like the tool is a great first step.

Choosing the Right Laser Cutting Machine for Wood

When it comes to selecting a laser cutting machine for wood, there are several factors to consider. These include the power of the laser, the size of the work area, and the type of materials you plan to cut. For example, if you’re working with thicker hardwoods or need to make deep cuts, a higher-powered laser may be necessary.

One popular option for woodworkers is the machine. This tool is designed specifically for cutting and engraving wood, offering features like adjustable laser power, high-speed processing, and compatibility with a wide range of materials. Whether you’re creating custom furniture, decorative items, or signage, this machine can help you achieve professional-grade results.

Before making a purchase, it’s important to research different models and read reviews to ensure you’re getting the best tool for your needs. Consider factors like ease of use, maintenance requirements, and customer support when choosing a laser cutting machine.

Applications of Laser Cutting Wood

Laser cutting wood is incredibly versatile and can be used in a wide range of applications. Here are some common uses:

- Furniture Making: Create custom tables, chairs, and other furniture with intricate designs and precise cuts.

- Decorative Items: Produce wall art, cutting boards, and other decorative pieces with unique patterns and textures.

- Signage: Laser-cut signs offer a professional look that can’t be matched by traditional methods.

- Toys and Models: Craft detailed models and toys with precise cuts and engravings.

- Packaging: Use laser cutting to create custom packaging solutions with unique shapes and designs.

The possibilities are endless when it comes to laser cutting wood. Whether you’re working on a small-scale project or running a full-fledged production line, this technology can help you achieve your creative vision.

Tips for Getting Started with Laser Cutting Wood

If you’re new to laser cutting wood, here are some tips to keep in mind:

- Start Small: Begin with simple designs and gradually work your way up to more complex projects as you gain experience.

- Experiment with Materials: Try different types of wood and thicknesses to see how they respond to the laser beam.

- Fine-Tune Settings: Adjust the laser power, speed, and focus distance to achieve the best results for your project.

- Use Protective Gear: Always wear safety goggles and ensure proper ventilation when working with laser cutting machines.

- Read the Manual: Take time to familiarize yourself with the machine’s features and settings before starting your first project.

By following these tips, you can maximize your success with laser cutting wood and create stunning projects that showcase your skills. With a reliable machine like the tool, you’ll be well on your way to mastering this exciting technology.

Conclusion

Laser cutting wood has opened up new possibilities for woodworkers of all levels. With its precision, versatility, and efficiency, it’s no wonder that this technology is becoming increasingly popular in both hobbyist and professional settings. Whether you’re creating custom furniture, decorative items, or signage, laser cutting offers a way to bring your designs to life with stunning accuracy.

If you’re looking for a tool that can take your woodworking projects to the next level, consider investing in a high-quality laser cutting machine like the tool. With the right equipment and a little practice, you can unlock your creative potential and produce beautiful, professional-grade results every time.

So why wait? Start exploring the world of laser cutting wood today and see how it can transform your woodworking projects!