Exploring the Capabilities of a Metal Laser Cutting Machine

Laser technology has revolutionized the manufacturing industry, offering precise, efficient, and versatile solutions for various applications. Among these innovations, the metal laser cutting machine stands out as a cornerstone of modern fabrication. This article delves into the functionalities, benefits, and considerations surrounding this advanced tool, providing readers with a comprehensive understanding of its role in today’s industrial landscape.

What is a Metal Laser Cutting Machine?

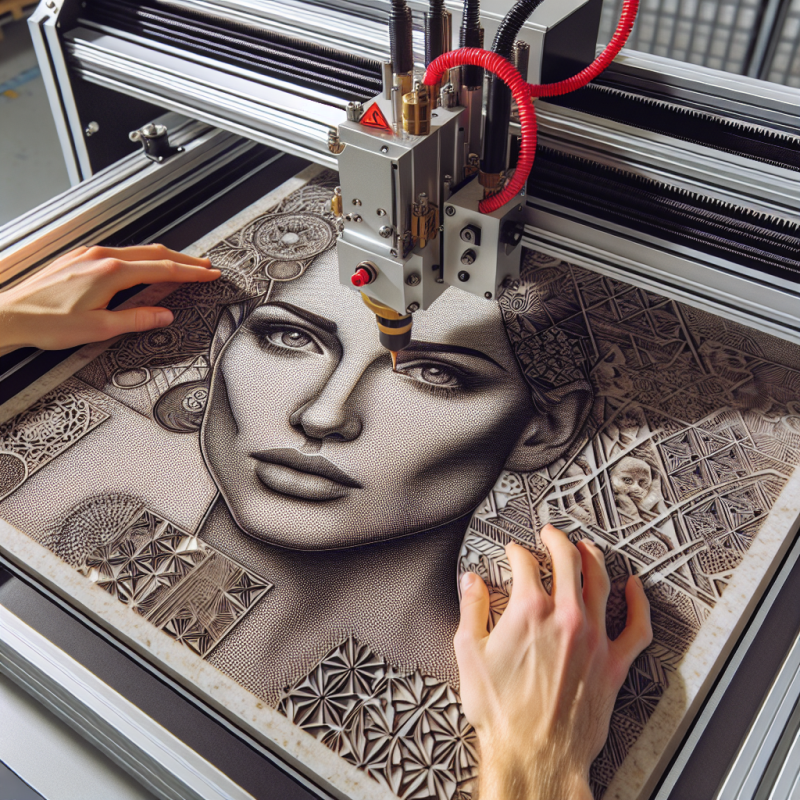

A metal laser cutting machine is a highly specialized device designed to cut through various types of metals with unparalleled precision. Unlike traditional cutting methods that rely on mechanical saws or blades, this machine uses a focused laser beam to melt, burn, or vaporize the material being cut. The process is not only faster but also produces cleaner edges and more intricate designs.

The CO2 laser engraver, as highlighted by , is a prime example of this technology. It combines cutting, engraving, and marking capabilities into one compact unit, making it an invaluable asset for industries ranging from automotive to jewelry manufacturing.

How Does a Metal Laser Cutting Machine Work?

To understand the functionality of a metal laser cutting machine, it’s essential to break down its components and processes. At the heart of this technology is the laser source, which generates a high-energy beam of light. This beam is then focused onto the material being cut through lenses or mirrors, creating intense heat that either melts, burns, or vaporizes the target area.

The machine operates on three primary principles:

- Pulsed Cutting: The laser emits short bursts of energy to remove small sections of material at a time.

- Continuous Cutting: A steady beam is used for cutting through thicker materials or achieving smoother edges.

- Assisted Gas Cutting: In some cases, an assist gas like oxygen or nitrogen is applied to enhance the cutting speed and quality.

The precision of these machines ensures minimal material waste and maximizes efficiency. This makes them ideal for industries where accuracy and cost-effectiveness are paramount.

Applications of a Metal Laser Cutting Machine

The versatility of the metal laser cutting machine is one of its most appealing features. It can be used in a wide range of applications, including:

- Prototype Development: Quickly create precise prototypes for testing and design validation.

- Custom Parts Manufacturing: Produce complex geometries that are difficult or impossible to achieve with traditional methods.

- Jewelry Making: Engrave intricate designs on precious metals like gold, silver, and platinum.

- Automotive Industry: Cut and shape components for vehicles, ensuring high precision and durability.

- Signage Production: Create custom signs with detailed engravings and cutouts.

The ability to work with various materials, including stainless steel, aluminum, titanium, and even non-metals like acrylic, further expands its applicability. This makes it a go-to solution for businesses seeking a versatile and efficient cutting tool.

Advantages of Using a Metal Laser Cutting Machine

Switching to a metal laser cutting machine offers numerous benefits over conventional cutting methods. Some of the key advantages include:

- Precision and Accuracy: The laser beam’s focus ensures minimal deviation, resulting in highly accurate cuts.

- Speed: Compared to manual or mechanical cutting, laser technology significantly reduces processing time.

- Minimal Material Waste: The focused beam minimizes heat-affected zones, preserving the integrity of the material and reducing waste.

- Versatility: Capable of handling various materials and thicknesses, it caters to a wide range of industrial needs.

- Cost-Effective: Despite the initial investment, the long-term savings from reduced material waste and faster production justify its value.

These benefits make the metal laser cutting machine an indispensable tool for businesses aiming to enhance their productivity and competitiveness in the market.

Choosing the Right Metal Laser Cutting Machine

With numerous options available, selecting the right metal laser cutting machine can be overwhelming. Key factors to consider include:

- Budget: Determine your budget and prioritize features that align with your specific needs.

- Material Thickness: Choose a machine capable of handling the thickness of materials you work with regularly.

- Beam Quality: Higher-quality beams ensure better precision and finish.

- Software Compatibility: Ensure the machine is compatible with your existing CAD/CAM software for seamless integration.

- After-Sales Support: Opt for manufacturers offering comprehensive support, including maintenance and upgrades.

Investing in a reliable machine like the from trusted brands ensures long-term satisfaction and productivity.

Maintenance and Safety Considerations

While metal laser cutting machines offer immense benefits, proper maintenance and safety protocols are crucial for optimal performance and longevity. Regular cleaning of the optics, checking gas flow, and monitoring laser alignment are essential tasks to perform. Additionally, operators must wear protective gear, such as goggles and gloves, to prevent injuries from the intense laser beam or flying debris.

Training staff on safe procedures is equally important. Understanding how to handle emergencies and shut down the machine in case of malfunctions ensures a safer working environment.

The Future of Metal Laser Cutting

As technology continues to evolve, so does the potential of metal laser cutting machines. Innovations such as higher-powered lasers, advanced software interfaces, and integration with automation systems promise even greater efficiency and precision in the future. Businesses that embrace these advancements will undoubtedly gain a competitive edge in their respective industries.

Conclusion

The metal laser cutting machine has emerged as a transformative tool in modern manufacturing, offering unparalleled precision, versatility, and efficiency. Its ability to handle a wide range of materials and applications makes it an essential investment for businesses aiming to stay competitive. By understanding its functionality, benefits, and proper usage, companies can unlock the full potential of this groundbreaking technology.

If you’re looking to enhance your production capabilities, consider exploring the options available from trusted manufacturers like . Embracing this innovation could be the key to unlocking new opportunities and achieving greater success in your industry.