Exploring the Precision and Efficiency of Laser Cutting Machines for Metal

Laser cutting machines have revolutionized the way we shape and design metal products. From intricate engravings to precise cuts, these machines offer unmatched accuracy and versatility. If you’re looking to enhance your metalworking capabilities, a laser cutting machine for metal could be the perfect solution. In this article, we’ll explore everything you need to know about laser cutting machines for metal, including their applications, advantages, and how they can transform your projects.

What is a Laser Cutting Machine?

A laser cutting machine uses focused light beams to cut or engrave materials with extreme precision. Unlike traditional cutting methods, which rely on mechanical tools, laser cutting machines use heat generated by the laser beam to melt, burn, or vaporize the material. This process is not only faster but also produces cleaner edges and more detailed designs. For metalworking, this technology has become indispensable due to its ability to handle a wide range of materials, including steel, aluminum, stainless steel, and more.

Applications of Laser Cutting Machines for Metal

Laser cutting machines are incredibly versatile and can be used in various industries. Here are some common applications:

- Precise metal fabrication: From creating custom parts to producing intricate designs, laser cutting machines excel at delivering high-precision cuts.

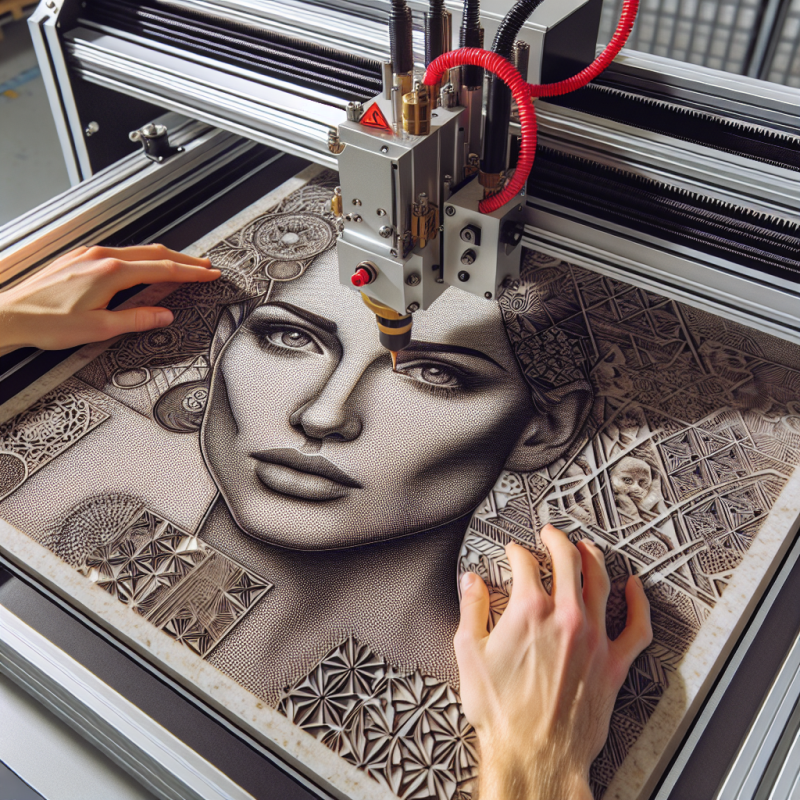

- Engraving and marking: Businesses often use these machines to engrave logos, serial numbers, or other markings on metal products.

- Artistic designs: Artists can create detailed and complex patterns on metal surfaces using laser cutting technology.

- Prototyping: Quickly produce prototypes for testing and validation purposes with minimal material waste.

Advantages of Using a Laser Cutting Machine for Metal

There are several reasons why businesses and hobbyists alike are turning to laser cutting machines for metal:

- High precision: The laser beam is incredibly narrow, allowing for intricate details and clean cuts without damaging the surrounding material.

- Speed and efficiency: Laser cutting machines can complete tasks much faster than traditional methods, reducing production time and costs.

- Minimal material waste: Since the laser beam only affects the target area, there is little to no wasted material during the cutting process.

- Versatility: These machines can handle a wide range of materials and thicknesses, making them suitable for various projects.

- Ease of use: Modern laser cutting machines are equipped with user-friendly software that simplifies the design and cutting process.

How to Choose the Right Laser Cutting Machine for Metal?

Selecting the right laser cutting machine depends on your specific needs and budget. Here are some factors to consider:

- Type of laser: There are different types of lasers, such as CO₂ and fiber lasers. Fiber lasers are often preferred for metal cutting due to their higher efficiency and longer lifespan.

- Cutting capacity: Determine the thickness of the metal you plan to cut. Most machines specify their maximum cutting capacity in terms of material thickness.

- Software compatibility: Ensure the machine is compatible with your design software and operating system for seamless integration into your workflow.

- Budget: Laser cutting machines vary greatly in price, so it’s important to set a budget that aligns with your needs and expectations.

Tips for Maintaining Your Laser Cutting Machine

To ensure optimal performance and longevity of your laser cutting machine, follow these maintenance tips:

- Clean the machine regularly: Dust and debris can interfere with the laser beam’s accuracy, so clean the machine after each use.

- Check the optics: The mirrors and lenses inside the machine need to be free of dirt and damage. Replace them if they show signs of wear or degradation.

- Monitor cooling systems: Ensure that the cooling system is functioning properly to prevent overheating during prolonged use.

- Calibrate the machine periodically: Regular calibration ensures consistent and accurate cuts over time.

Frequently Asked Questions About Laser Cutting Machines for Metal

Here are answers to some common questions about laser cutting machines:

- How thick can a laser cutting machine cut metal? The maximum thickness depends on the type of laser and machine specifications. For example, fiber lasers can typically cut steel up to 20mm thick.

- Can laser cutting machines be used for non-metal materials?

- Are laser cutting machines safe to use?

Where to Buy a Laser Cutting Machine for Metal?

If you’re interested in purchasing a laser cutting machine, there are several reputable manufacturers and suppliers available. One popular option is the laser cutting machine for metal offered by [Your Supplier Name]. Their machines are known for their high precision, durability, and user-friendly design.

The Future of Laser Cutting Technology

Laser cutting technology continues to evolve, with advancements in speed, accuracy, and material compatibility. As industries demand more precise and efficient solutions, laser cutting machines will likely become even more integral to metalworking processes. Whether you’re a small business owner or a hobbyist, investing in a laser cutting machine for metal can open up new possibilities for your projects.

In conclusion, a laser cutting machine is an invaluable tool for anyone working with metal. Its precision, versatility, and efficiency make it a must-have for modern manufacturing and design. If you’re ready to take your metalworking skills to the next level, consider exploring the options available at [Your Supplier Name] today.