The Ultimate Guide to Laser Cutting Machines for Metal

Are you looking for a precise and efficient way to cut metal? If so, you’ve likely come across the term laser cutting machine for metal. But what exactly is it, and how can it benefit your projects? In this article, we’ll explore everything you need to know about laser cutting machines for metal, including their advantages, applications, and how they work. Let’s dive in!

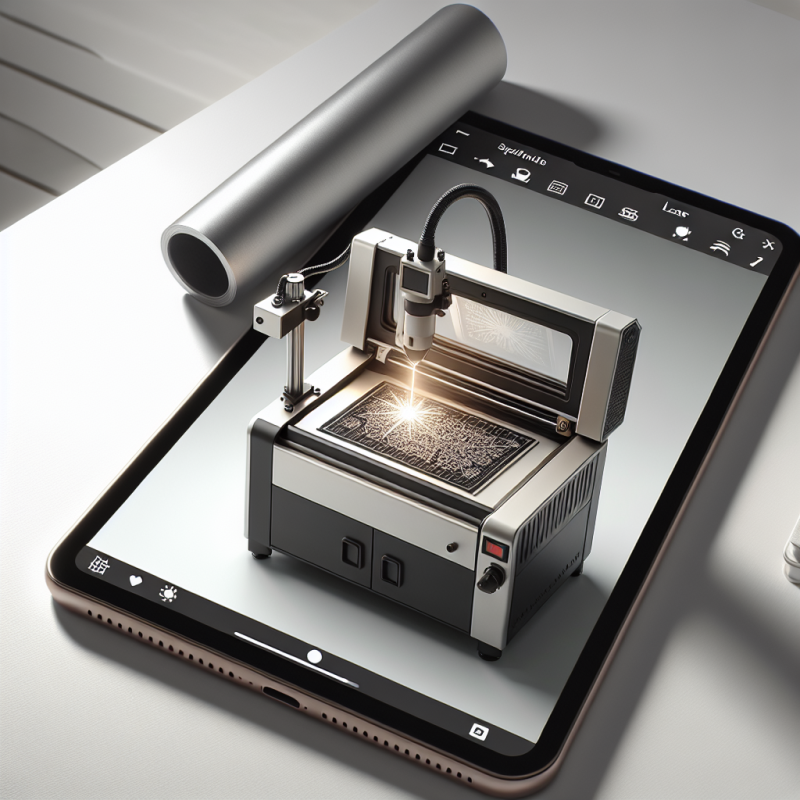

What Is a Laser Cutting Machine for Metal?

A laser cutting machine for metal is a sophisticated tool designed to cut and engrave various types of metals with precision. Unlike traditional cutting methods, which often rely on mechanical tools or flames, laser cutting uses a focused beam of light to melt, burn, or vaporize material away from the workpiece. This process is not only faster but also produces cleaner cuts with minimal waste.

The machine operates by directing a high-powered laser through optics and mirrors to a focal point on the metal surface. The intensity of the laser beam creates an extremely localized heat source, which melts or vaporizes the metal in the intended cutting path. This method is ideal for intricate designs, tight tolerances, and repetitive tasks, making it a favorite among manufacturers, artists, and hobbyists alike.

Advantages of Using a Laser Cutting Machine for Metal

There are numerous benefits to using a laser cutting machine for metal. Here are some of the most compelling reasons:

- Precision and Accuracy: Laser cutting machines can achieve tolerances as tight as ±0.001 inches, ensuring consistent and high-quality results every time.

- Speed: Compared to traditional methods like plasma or oxy-acetylene cutting, laser cutting is significantly faster, especially for complex designs.

- Minimal Material Waste: The focused beam of light minimizes heat-affected zones and reduces the amount of material removed during the cutting process.

- Versatility: Laser cutting machines can work with a wide range of materials, including steel, stainless steel, aluminum, brass, and titanium.

- Cost-Effective: Despite the initial investment, laser cutting machines offer long-term savings due to their efficiency and reduced material waste.

These advantages make laser cutting machines an excellent choice for industries such as automotive, aerospace, jewelry, and electronics, where precision and speed are critical.

Applications of Laser Cutting Machines for Metal

Laser cutting machines for metal have a wide range of applications across various industries. Here are some common uses:

- Metal Engraving: Create intricate designs, logos, or text on metal surfaces with unmatched precision.

- Cutting Complex Shapes: Produce curved or angular cuts that would be difficult or impossible to achieve with traditional tools.

- Prototyping: Quickly and accurately prototype new designs without the need for expensive tooling.

- Jewelry Making: Engrave or cut intricate patterns on precious metals like gold, silver, or platinum.

- Signage Production: Cut metal letters, numbers, and symbols for high-quality signage.

If you’re wondering how to get started with laser cutting for your projects, it’s essential to understand the basics of how these machines work and what factors to consider when choosing one.

How Does a Laser Cutting Machine for Metal Work?

A laser cutting machine for metal operates on the principle of focused light energy. The process involves several key steps:

- Laser Generation: A laser source generates a high-powered beam of coherent light.

- Optical Focusing: The laser beam is directed through mirrors and lenses to focus on the metal surface, creating an intense heat source.

- Metal Vaporization or Melting: The concentrated heat melts or vaporizes the metal along the intended cutting path.

- Cutting and Engraving: As the laser moves across the metal surface, it precisely cuts or engraves the desired design or pattern.

The machine can be programmed with CAD (Computer-Aided Design) software to create custom patterns or shapes, making it highly adaptable to different projects. This level of automation and precision is unmatched by traditional cutting methods, which often require manual adjustments and multiple tools.

Factors to Consider When Choosing a Laser Cutting Machine for Metal

If you’re in the market for a laser cutting machine for metal, there are several factors to keep in mind:

- Laser Power: Higher power lasers can cut through thicker materials but may require more energy and space.

- Cutting Speed: Determine how quickly you need the machine to complete tasks, as this will influence your choice of model.

- Precision Requirements: Consider the level of detail and accuracy needed for your projects. High-precision machines are ideal for intricate designs.

- Budget: Laser cutting machines vary widely in price, so it’s essential to set a budget and find a model that offers the best value for your needs.

By evaluating these factors, you can select a machine that aligns with your project requirements and long-term goals.

Tips for Getting Started with Laser Cutting Machines

If you’re new to laser cutting machines, here are some tips to help you get started:

- Start Small: Begin with simple designs or patterns to familiarize yourself with the machine’s capabilities.

- Experiment with Materials: Test different types of metals and thicknesses to understand how the laser interacts with each material.

- Use Proper Safety Gear: Always wear protective eyewear and ensure your work area is well-ventilated to avoid inhaling fumes from the cutting process.

- Upgrade Software: Invest in high-quality CAD software to maximize the machine’s potential and create more complex designs.

With practice and experimentation, you’ll soon be able to produce professional-grade metal cuts and engravings with ease.

Frequently Asked Questions About Laser Cutting Machines for Metal

Here are some common questions people have about laser cutting machines for metal:

- Can I use a laser cutting machine for thick metals? Yes, but the thickness capacity depends on the machine’s power. Higher power lasers can handle thicker materials.

- Is laser cutting safe? Yes, as long as proper safety precautions are followed, such as wearing protective gear and ensuring good ventilation.

- How much does a laser cutting machine cost? Prices vary widely depending on the model and specifications, ranging from a few thousand to tens of thousands of dollars.

If you’re still unsure about whether a laser cutting machine for metal is right for your projects, consider trying out a small-scale machine or consulting with professionals in the field.

Conclusion

A laser cutting machine for metal is an invaluable tool for anyone looking to achieve precise, efficient, and high-quality cuts on metal surfaces. With its ability to handle a wide range of materials and produce intricate designs, it’s no wonder that laser cutting has become a go-to method in numerous industries.

Whether you’re a hobbyist, artist, or manufacturer, investing in a laser cutting machine for metal can open up new possibilities for your projects. Just remember to take the time to research and choose the right machine for your needs, and always prioritize safety when operating it. Happy cutting!