The Art and Science of Laser Engraving Stainless Steel: A Comprehensive Guide

Laser engraving stainless steel has become a cornerstone in modern manufacturing, offering unparalleled precision and durability for various applications. Whether you’re creating intricate designs for jewelry, marking components in the automotive industry, or crafting decorative items, laser engraving stands out as a versatile and efficient solution. In this article, we’ll explore the process, benefits, and considerations of laser engraving stainless steel, while also addressing common questions to help you make informed decisions.

What is Laser Engraving?

Laser engraving is a cutting-edge technology that uses a focused beam of light to etch or cut materials with extreme precision. Unlike traditional methods, laser engraving offers non-contact processing, which means there’s no physical wear on the material being engraved. This makes it ideal for delicate or high-value items like stainless steel, where maintaining the integrity of the surface is crucial.

The process involves directing a high-powered laser at the material, melting or vaporizing tiny portions to create detailed patterns or text. The result is a permanent mark that is resistant to wear and tear, making it perfect for industrial, decorative, and promotional purposes.

Why Laser Engraving Stainless Steel?

Stainless steel is renowned for its durability, corrosion resistance, and sleek appearance, which makes it a popular choice in numerous industries. Laser engraving stainless steel enhances these properties by adding personalized or functional markings without compromising the material’s structural integrity.

One of the key advantages of laser engraving stainless steel is the ability to achieve intricate designs with high precision. Whether you’re creating delicate engravings for jewelry or bold, industrial-grade markings for machinery, laser engraving delivers consistent results every time. Additionally, the process is faster and more cost-effective than traditional methods, making it a favorite among manufacturers and artists alike.

How Does Laser Engraving Work?

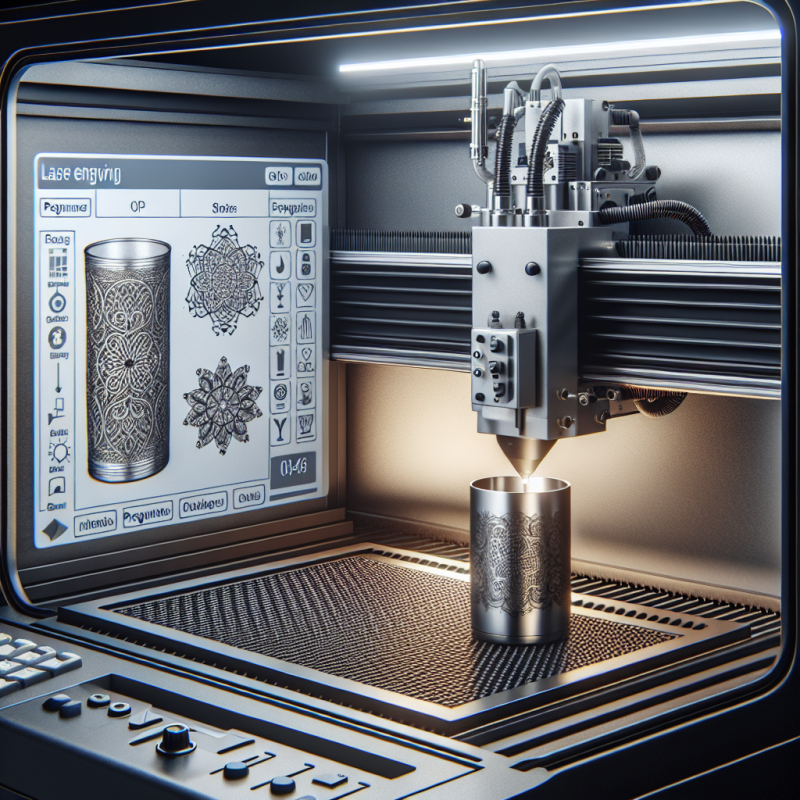

To understand how laser engraving works, let’s break down the process into its essential components:

- Design Creation: The first step is to create a digital design using specialized software. This design can include text, images, or patterns that will be engraved onto the stainless steel.

- Laser Machine Setup: Once the design is ready, it’s loaded into the laser engraving machine. Operators adjust settings such as laser power, speed, and focus to ensure optimal results for the specific material being engraved.

- Engraving Process: The laser beam is directed at the stainless steel, melting or vaporizing the material in precise locations. This creates a permanent mark that can be shallow or deep depending on the application requirements.

The use of advanced machines like the machine ensures that even the most complex designs are executed with precision and consistency. This level of control is unmatched by traditional engraving methods, making it a preferred choice for industries where accuracy is paramount.

Applications of Laser Engraving Stainless Steel

Laser engraving stainless steel finds applications across various sectors due to its versatility and durability. Some common uses include:

- Jewelry Making: Creating intricate designs, personalized engravings, and delicate patterns on stainless steel jewelry pieces.

- Automotive Industry: Marking parts with serial numbers, logos, or other identifiers for traceability and branding purposes.

- Medical Devices: Engraving precise markings on surgical instruments or implants to ensure proper identification and compliance with industry standards.

The ability to create durable and permanent marks makes laser engraving stainless steel ideal for applications where longevity and readability are critical. Whether it’s for decorative, functional, or promotional purposes, the possibilities are endless.

Advantages of Laser Engraving Stainless Steel

Beyond its versatility, laser engraving stainless steel offers several advantages that make it a preferred choice over traditional methods:

- Precision and Accuracy: The focused laser beam ensures that even the most intricate designs are reproduced with pinpoint accuracy. This is particularly important for industries like jewelry and medical devices, where precision is critical.

- Durability: Laser engravings on stainless steel are resistant to wear and tear, ensuring that marks remain legible over time. This makes it ideal for components exposed to harsh environments or frequent use.

- Speed and Efficiency: Modern laser engraving machines can process large volumes of work quickly, reducing production times and costs compared to traditional methods.

These advantages make laser engraving stainless steel a cost-effective and reliable solution for businesses looking to enhance their products or streamline their manufacturing processes.

Frequently Asked Questions

If you’re new to laser engraving, here are some common questions and answers to help guide you:

- Is laser engraving suitable for all types of stainless steel? Yes, most grades of stainless steel can be laser engraved. However, it’s important to choose the right machine settings based on the specific type of stainless steel being used.

- Can I remove a laser engraving from stainless steel? Once engraved, the marks are permanent and cannot be easily removed without damaging the material. This makes laser engraving ideal for applications where permanence is required.

- How deep can a laser engraving go on stainless steel? The depth of the engraving depends on the power and duration of the laser beam. Modern machines allow operators to control these settings to achieve the desired depth, whether shallow or deep.

Conclusion

Laser engraving stainless steel is a powerful tool that combines precision, durability, and efficiency, making it an invaluable asset in various industries. With its ability to create intricate designs and permanent marks, it’s no wonder that laser engraving has become the go-to method for businesses looking to enhance their products or streamline their manufacturing processes.

If you’re considering laser engraving stainless steel, investing in a high-quality machine like the machine can ensure that your projects are completed with ease and precision. Whether you’re creating decorative pieces or functional components, the benefits of laser engraving make it a worthwhile investment for any business.