Discover the Precision of Laser Engraving Products: Your Ultimate Guide

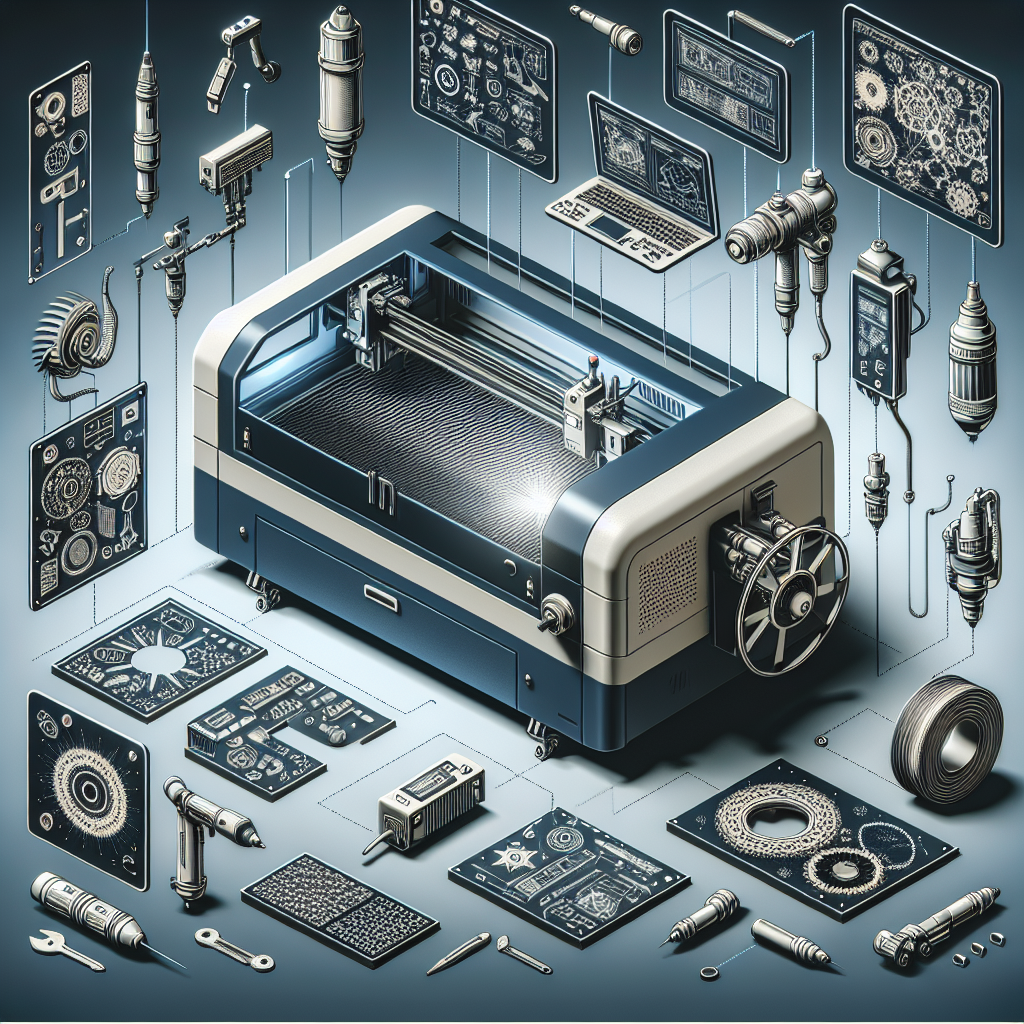

Laser engraving has revolutionized the way we create intricate designs, patterns, and markings on various materials. With advancements in technology, laser engraving products have become an essential tool for industries ranging from manufacturing to custom craftsmanship. Whether you’re looking to create personalized jewelry, industrial parts, or artistic masterpieces, laser engraving offers unparalleled precision and versatility.

What is Laser Engraving?

Laser engraving uses a focused beam of light to remove material from the surface of an object, leaving behind a permanent mark. Unlike traditional engraving methods, which often require physical contact with the material, laser engraving is non-contact and highly precise. This process allows for intricate details and complex designs that would be difficult or impossible to achieve manually.

The key advantage of laser engraving lies in its ability to work on a wide range of materials, including metals, plastics, wood, glass, and even textiles. This versatility makes it an ideal choice for various industries. For example, in the jewelry industry, laser engraving is used to create delicate engravings on precious metals like gold and silver. In the automotive sector, it’s employed to mark parts with serial numbers or logos.

How Does Laser Engraving Work?

Laser engraving systems typically consist of a laser source, a control unit, and a worktable where the material is placed. The laser beam is directed by mirrors and lenses to focus on the surface of the material. When the laser hits the material, it vaporizes or burns away tiny particles, creating the desired design.

The process begins with designing the engraving using specialized software. This software converts the design into a series of instructions that guide the laser beam. Once the design is programmed, the laser machine can replicate it with extreme accuracy, even on curved or irregular surfaces.

Applications of Laser Engraving Products

Laser engraving products are used in numerous industries due to their precision and adaptability. Some common applications include:

- Jewelry Making: Creating custom engravings on rings, necklaces, and other precious metals.

- Automotive Industry: Marking parts with serial numbers, logos, or patterns for identification and branding.

- Medical Devices: Engraving surgical instruments and implants with precise markings for traceability.

- Furniture Making: Adding decorative designs or initials to wooden furniture surfaces.

- Textile Printing: Transferring intricate patterns onto fabrics using laser technology.

The versatility of laser engraving makes it a go-to solution for businesses seeking high-quality, customized products. Whether you’re working with small batches or large-scale production, these machines can handle the demand efficiently.

Benefits of Using Laser Engraving Products

Incorporating laser engraving products into your workflow offers numerous advantages:

- Precision and Accuracy: Laser beams can create designs with extreme precision, ensuring every detail is captured perfectly.

- Speed and Efficiency: Once programmed, laser machines can produce engravings quickly, reducing production time.

- Versatility: Works on a wide range of materials, making it suitable for various industries and projects.

- Durability: Engraved marks are permanent and resistant to wear, ensuring long-lasting results.

- Ease of Use: Modern laser engraving systems come with user-friendly interfaces, making them accessible even for those new to the technology.

These benefits make laser engraving a cost-effective and reliable solution for businesses looking to enhance their production capabilities. Whether you’re a small artisan or a large manufacturing company, these machines can meet your needs with ease.

Choosing the Right Laser Engraving Machine

With so many options available in the market, selecting the right laser engraving machine can be overwhelming. Here are some factors to consider when making your choice:

- Type of Material: Determine the types of materials you’ll be working with, as different machines are optimized for specific substrates.

- Power Output: Higher power lasers are better suited for thick or dense materials, while lower power lasers work well for delicate surfaces.

- Budget: Consider your budget and weigh it against the features and capabilities of the machine.

- Software Compatibility: Ensure the machine is compatible with the design software you’re using to avoid compatibility issues.

- Maintenance Requirements: Some machines require more frequent maintenance than others, so factor this into your decision.

Taking these factors into account will help you choose a laser engraving machine that aligns with your business needs and provides long-term value.

Frequently Asked Questions About Laser Engraving

Here are some common questions people have about laser engraving:

- Is laser engraving safe? Yes, as long as proper safety precautions are followed, such as wearing protective eyewear and operating the machine in a well-ventilated area.

- Can laser engraving be done on curved surfaces? Absolutely! Modern laser machines can handle complex shapes and curves with ease.

- How long does it take to learn how to use a laser engraver? It depends on your prior experience, but most machines come with intuitive interfaces that make the learning process straightforward.

The Future of Laser Engraving

Laser engraving technology continues to evolve, offering even more possibilities for businesses and artisans. With advancements in AI and automation, laser engravers are becoming faster, more precise, and easier to use than ever before.

As demand for customized and high-quality products grows, laser engraving is poised to play an increasingly important role in various industries. Whether you’re looking to enhance your current operations or explore new business opportunities, investing in a reliable laser engraving machine could be the key to unlocking your creative potential.

Conclusion

Laser engraving products have revolutionized the way we create and customize items across multiple industries. Their precision, versatility, and efficiency make them an invaluable tool for businesses of all sizes. By understanding how these machines work and what they can offer, you can make informed decisions about whether laser engraving is the right choice for your needs.

If you’re ready to take your production capabilities to the next level, consider exploring the wide range of and engraving solutions available. With the right equipment, you can unlock endless possibilities and create products that stand out in quality and craftsmanship.

Happy creating! 🚀