The Art and Science of Wood Laser Engraving: A Comprehensive Guide

Laser engraving has revolutionized the way we personalize and decorate materials, especially wood. With advancements in technology, wood laser engraving has become a popular method for creating intricate designs, logos, patterns, and text on wooden surfaces. Whether you’re a hobbyist, an artist, or a professional craftsman, understanding the process and benefits of laser engraving can open up endless creative possibilities. In this article, we will explore everything you need to know about wood laser engraving, including its advantages, applications, and how to choose the right equipment for your projects.

The Basics of Wood Laser Engraving

Laser engraving is a precise and efficient method of marking or cutting materials using a focused beam of light. When it comes to wood, laser engraving uses high-powered lasers to remove layers of the material, creating permanent and detailed designs. Unlike traditional carving methods, which can be time-consuming and labor-intensive, laser engraving offers unparalleled accuracy and speed.

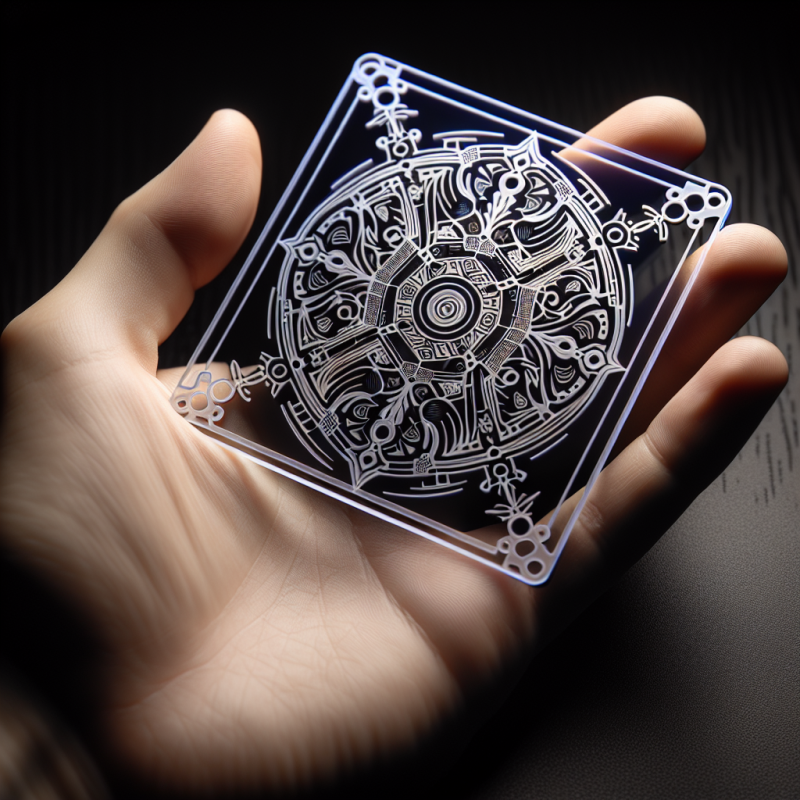

The process involves directing a focused laser beam at the surface of the wood. The laser heats the wood rapidly, causing it to vaporize or char, depending on the intensity and duration of the beam. This creates a permanent mark that can range from subtle textures to deep carvings. The result is a professional-looking finish that enhances the natural beauty of the wood.

One of the most significant advantages of wood laser engraving is its versatility. It can be used on various types of wood, including oak, maple, walnut, and plywood. Additionally, it allows for intricate designs that would be nearly impossible to achieve with traditional carving tools. This makes it an ideal choice for custom furniture, decorative items, and personalized gifts.

Applications of Wood Laser Engraving

The applications of wood laser engraving are vast and varied. Here are some common uses:

- Creating custom furniture with intricate designs or patterns

- Making personalized gifts, such as engraved wooden boxes, cutting boards, or plaques

- Designing decorative items like wall art, photo frames, and clocks

- Engraving logos or branding on wooden products for businesses

- Producing musical instruments with detailed engravings

- Restoring antique furniture by repairing or adding new designs

Laser engraving is also widely used in the craft and hobby industries. Engravers can create unique pieces for events, such as wedding favors, anniversary gifts, and corporate giveaways. The ability to produce high-quality, detailed engravings quickly makes it a favorite among both amateurs and professionals.

Advantages of Wood Laser Engraving

There are several reasons why wood laser engraving has become so popular in recent years:

- Precision and Detail: Lasers can create extremely fine lines and intricate patterns that would be difficult or impossible to achieve manually.

- Speed: Laser engraving is much faster than traditional carving methods, making it ideal for large-scale projects or high-volume production.

- Non-Contact Process: Unlike mechanical cutting tools, lasers do not physically touch the wood. This reduces the risk of damaging the material and ensures a cleaner finish.

- Versatility: Laser engraving can be used on various types of wood and can produce both shallow engravings (for text or simple designs) and deep carvings (for complex patterns or relief work).

- Longevity: Laser-engraved designs are permanent and resistant to wear, ensuring that your projects will last for years.

These advantages make wood laser engraving a versatile and efficient tool for anyone looking to add a personal touch or professional finish to their wooden creations.

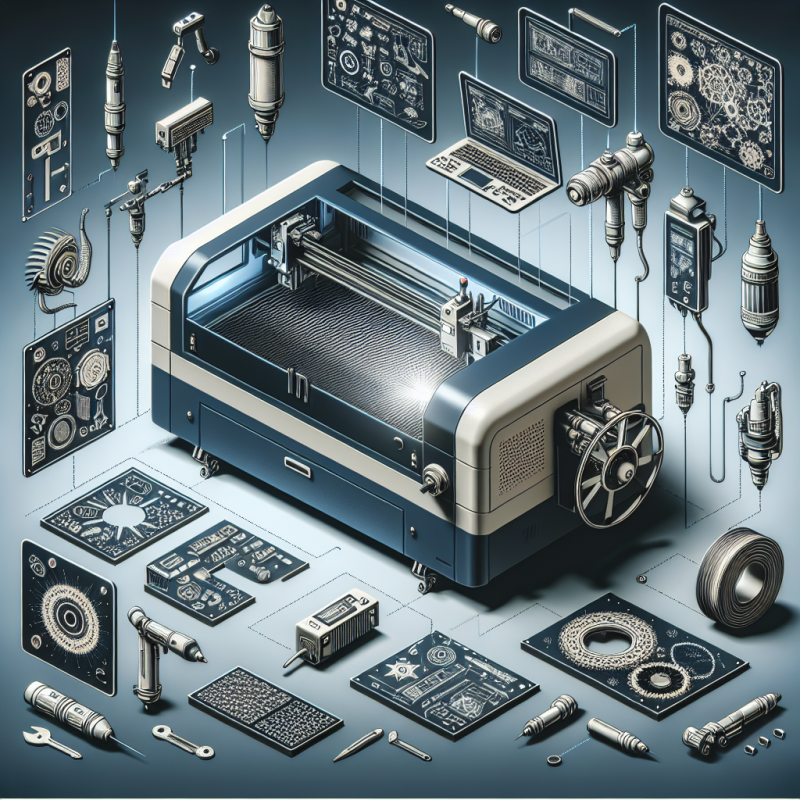

Choosing the Right Laser Engraver for Wood

If you’re interested in trying wood laser engraving, one of the first steps is selecting the right equipment. There are several factors to consider when choosing a laser engraver, including power output, wavelength, and software compatibility.

Power Output: The power of the laser determines how deep it can engrave into the wood. For shallow engravings (such as text or simple designs), a lower-power laser may suffice. However, for deeper carvings or detailed work, a higher-power laser is recommended.

Wavelength: Different wavelengths of lasers are better suited for different materials. For wood, a CO2 laser is typically the best choice because it provides optimal performance and results on organic materials like wood, acrylic, and leather.

Software Compatibility: Most laser engravers come with software that allows you to design your projects or import files from graphic design programs. Look for a machine that supports popular file formats such as SVG, DXF, and BMP to ensure compatibility with your existing designs.

If you’re just starting out, consider investing in a compact and user-friendly laser engraver like the . This machine is perfect for small-scale projects and offers high precision and ease of use.

Tips for Achieving the Best Results

To get the most out of your wood laser engraving projects, here are some tips to keep in mind:

- Preparation: Always ensure the wood surface is clean and free of dust or oils before engraving. Sanding the wood lightly can help improve the quality of the engraving.

- Focus: Properly focus the laser beam to achieve sharp and precise engravings. Most machines have an auto-focus feature, but manual adjustments may be necessary for certain projects.

- Speed and Power Settings: Experiment with different speed and power settings to find the optimal combination for your project. Too much power or too slow a speed can burn the wood excessively, while too little power may result in faint engravings.

- Test Runs: Always perform test runs on scrap wood before starting your final project. This will help you fine-tune your settings and ensure the desired outcome.

- Safety: Laser engraving involves high-powered lasers, so always follow safety guidelines. Wear protective eyewear and ensure proper ventilation to avoid inhaling fumes from the burning wood.

By following these tips, you can achieve professional-quality results with your wood laser engraving projects and bring your creative visions to life.

Frequently Asked Questions About Wood Laser Engraving

1. Can I use any type of wood for laser engraving?

Yes, most types of wood can be used for laser engraving. However, some species may require different settings due to their density or moisture content.

2. Is laser engraving permanent?

Yes, laser engravings are permanent and resistant to wear. They will not fade over time unless exposed to harsh conditions like extreme heat or chemicals.

3. Can I engrave on painted wood?

It is generally not recommended to engrave on painted wood, as the laser may burn through the paint layer and damage the underlying wood.

4. How long does it take to learn laser engraving?

The basics of wood laser engraving can be learned quickly with practice. However, mastering advanced techniques and achieving professional-level results may require more time and experience.

Conclusion

Wood laser engraving is a fascinating and versatile technique that combines precision, creativity, and technology to produce stunning results. Whether you’re looking to enhance your woodworking skills or start a new hobby, investing in a quality laser engraver can unlock a world of possibilities for your projects.

By understanding the basics of wood laser engraving, its applications, advantages, and how to choose the right equipment, you can take your wooden creations to the next level. So why not give it a try? With a little practice and experimentation, you’ll be creating beautiful and intricate designs in no time!