The Future of Precision Cutting: Introducing the Laser Grass Cutter Startup

Imagine a world where precision cutting meets efficiency, where intricate designs can be brought to life with ease, and where versatility is key. Welcome to the innovative world of , a groundbreaking solution for industries ranging from manufacturing to artistry. In this article, we will explore everything you need to know about this cutting-edge technology, its applications, benefits, and how it is revolutionizing the way we approach precision cutting tasks.

What is a CNC Laser Cutter?

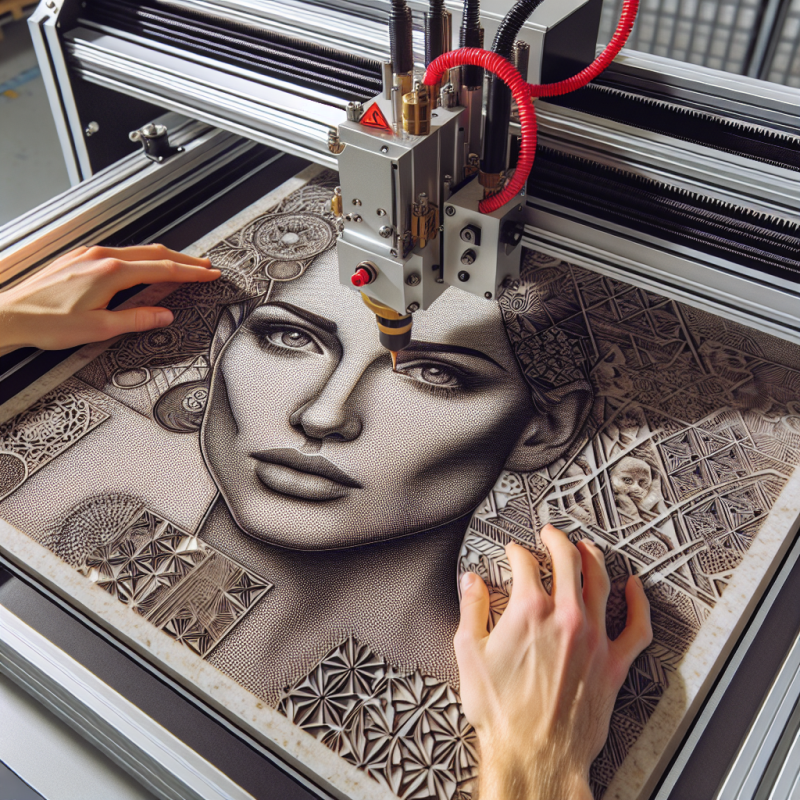

A CNC laser cutter stands for Computer Numerical Control laser cutter. It is a machine that uses a high-powered laser to cut, engrave, or etch materials with extreme precision. Unlike traditional cutting methods, which often require manual intervention and are prone to errors, CNC laser cutters operate with computer-controlled accuracy. This makes them ideal for industries where precision and consistency are paramount.

The model, in particular, is designed to handle a wide range of materials, including metal, acrylic, wood, and more. Its ability to switch between cutting and engraving modes makes it a versatile tool for businesses looking to streamline their production processes.

Applications of CNC Laser Cutters

CNC laser cutters have a vast array of applications across different industries. Here are some of the most common uses:

- Metal fabrication: Cutting and engraving metal sheets for components, parts, or decorative elements.

- Acrylic cutting: Creating signs, displays, and decorative items with precision and smooth edges.

- Woodworking: Etching intricate designs on wood for furniture, art pieces, or custom products.

- Engraving: Adding detailed text or graphics to materials like metal, stone, or plastic for branding or personalization.

The versatility of CNC laser cutters makes them a valuable asset for businesses looking to expand their capabilities without investing in multiple machines. With the , you can handle all these tasks with ease, ensuring consistent quality and precision every time.

Benefits of Using a CNC Laser Cutter

There are numerous benefits to incorporating a CNC laser cutter into your workflow. Let’s take a closer look at some of the key advantages:

- Precision and Accuracy: The computer-controlled system ensures that every cut or engraving is precise, reducing waste and improving product quality.

- Versatility: Capable of handling multiple materials and tasks, this machine can adapt to your changing project requirements.

- Efficiency: CNC laser cutters operate at high speeds, allowing you to complete projects faster than traditional methods.

- Reduced Labor Costs: By automating the cutting process, businesses can reduce reliance on manual labor and minimize errors.

- Eco-Friendly: The precision of laser cutting reduces material waste, making it an environmentally responsible choice.

These benefits make CNC laser cutters a smart investment for any business looking to enhance productivity, reduce costs, and deliver high-quality products to their customers. With the , you can enjoy all these advantages in a compact, user-friendly package.

How Does a CNC Laser Cutter Work?

Understanding the mechanics behind a CNC laser cutter can help you appreciate its capabilities fully. Here’s a simplified explanation of how it works:

- Design Creation: The first step is to create a digital design using CAD (Computer-Aided Design) software. This design specifies the cuts, engraving details, and other parameters required for the project.

- Programming: The design is then converted into a CNC program that instructs the machine on how to move the laser beam across the material.

- Laser Cutting: The laser beam, focused to a pinpoint, heats and melts or vaporizes the material along the programmed path. This creates precise cuts or engravings without physical contact with the material.

- Material Handling: Depending on the machine, materials can be fed manually or through an automated system for continuous operation.

The entire process is highly efficient and allows for complex designs to be executed with ease. This level of automation ensures that even intricate patterns can be replicated consistently, making CNC laser cutters a favorite among designers and manufacturers alike.

Choosing the Right CNC Laser Cutter

With so many options available in the market, selecting the right CNC laser cutter for your needs can be overwhelming. Here are some factors to consider when making your choice:

- Budget: Determine how much you are willing to invest and look for machines that offer the best value for money within your budget.

- Type of Material: Consider the types of materials you will be working with. Some laser cutters are better suited for certain materials than others.

- Size and Capacity: Think about the size of your projects and choose a machine that can accommodate your needs without being overly bulky.

- User-Friendliness: Look for machines with intuitive controls and easy-to-use software to minimize training time and maximize productivity.

The is designed with these factors in mind, offering a balance of affordability, versatility, and ease of use that makes it an excellent choice for both small businesses and large-scale operations.

Maintenance and Safety Tips

Like any precision tool, CNC laser cutters require proper maintenance to ensure optimal performance and longevity. Here are some tips to keep your machine running smoothly:

- Regular Cleaning: Dust and debris can accumulate inside the machine, so it’s essential to clean it regularly.

- Lens Care: The laser lens is a critical component. Keep it free from scratches and contaminants by using the proper cleaning solutions and techniques.

- Software Updates: Stay up-to-date with software updates to ensure your machine operates at peak efficiency and takes advantage of new features as they become available.

Safety should always be a priority when working with CNC laser cutters. Follow all safety guidelines provided by the manufacturer, including proper eyewear protection and adequate ventilation to handle any fumes generated during the cutting process.

The Future of Precision Cutting

As technology continues to evolve, CNC laser cutters are at the forefront of innovation in precision cutting. Their ability to combine speed, accuracy, and versatility makes them an indispensable tool for businesses across various industries. With the introduction of the , even more companies can benefit from this cutting-edge technology without breaking the bank.

If you’re looking to elevate your production capabilities and deliver high-quality, precision-cut products, it’s time to consider investing in a CNC laser cutter. With its numerous benefits and wide range of applications, it’s no wonder why businesses are turning to this innovative solution for their cutting needs. Whether you’re a small artisan or a large-scale manufacturer, the is the perfect tool to take your projects to the next level.