The Ultimate Guide to Laser Engraving Aluminium: Precision, Efficiency, and Creativity

Laser engraving aluminium has become one of the most popular methods for creating durable and high-quality engravings on metal surfaces. This innovative technology combines precision, speed, and versatility, making it an ideal choice for industries ranging from jewelry production to automotive manufacturing. In this comprehensive guide, we will explore the benefits, applications, and considerations of laser engraving aluminium, as well as provide insights into selecting the right equipment for your needs.

What is Laser Engraving Aluminium?

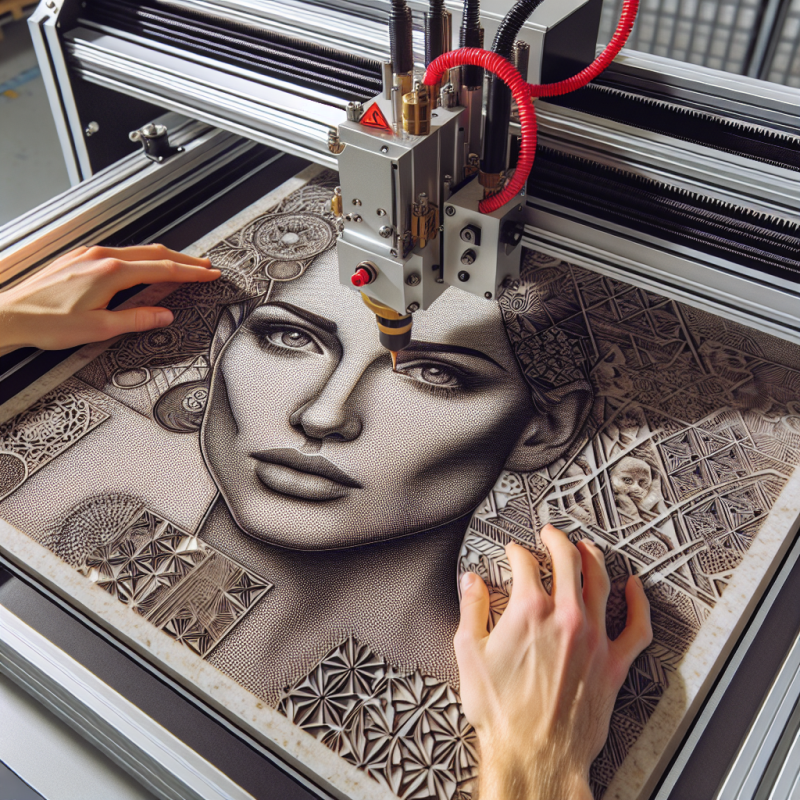

Laser engraving aluminium involves using a focused laser beam to remove material from the surface of an aluminum object, creating intricate designs or text. Unlike traditional engraving methods that use mechanical tools, laser engraving offers unparalleled precision and flexibility. The process is quick, non-contact, and produces minimal waste, making it an environmentally friendly option for many applications.

One of the key advantages of laser engraving aluminium is its ability to work on a wide range of materials, including stainless steel, titanium, and other metals. However, aluminium is particularly popular due to its reflective properties and relatively low melting point, which make it easier to engrave with lasers.

Why Choose Laser Engraving Aluminium?

There are several reasons why businesses and individuals are turning to laser engraving machines for their metalworking needs:

- Precision: Laser beams can create extremely fine details, making it possible to produce complex designs with exceptional accuracy.

- Speed: Compared to traditional engraving methods, laser engraving is much faster, reducing production time and costs.

- Durability: Engravings on aluminium are highly resistant to wear and tear, ensuring long-lasting results.

- Versatility: Laser engraving machines can handle a wide range of materials and project sizes, making them suitable for both small-scale and industrial applications.

Applications of Laser Engraving Aluminium

Laser engraving aluminium is used in various industries due to its versatility and precision. Some common applications include:

- Jewelry: Creating custom engravings on rings, bracelets, necklaces, and other accessories.

- Automotive: Engraving vehicle identification numbers (VINs), logos, or decorative elements on car parts.

- Electronics: Marking circuit boards, casing, and components with precise details.

- Fashion: Adding unique designs or brand logos to aluminium accessories like belts, buckles, and buttons.

- Medical: Engraving surgical instruments, implants, or other medical devices with identification marks.

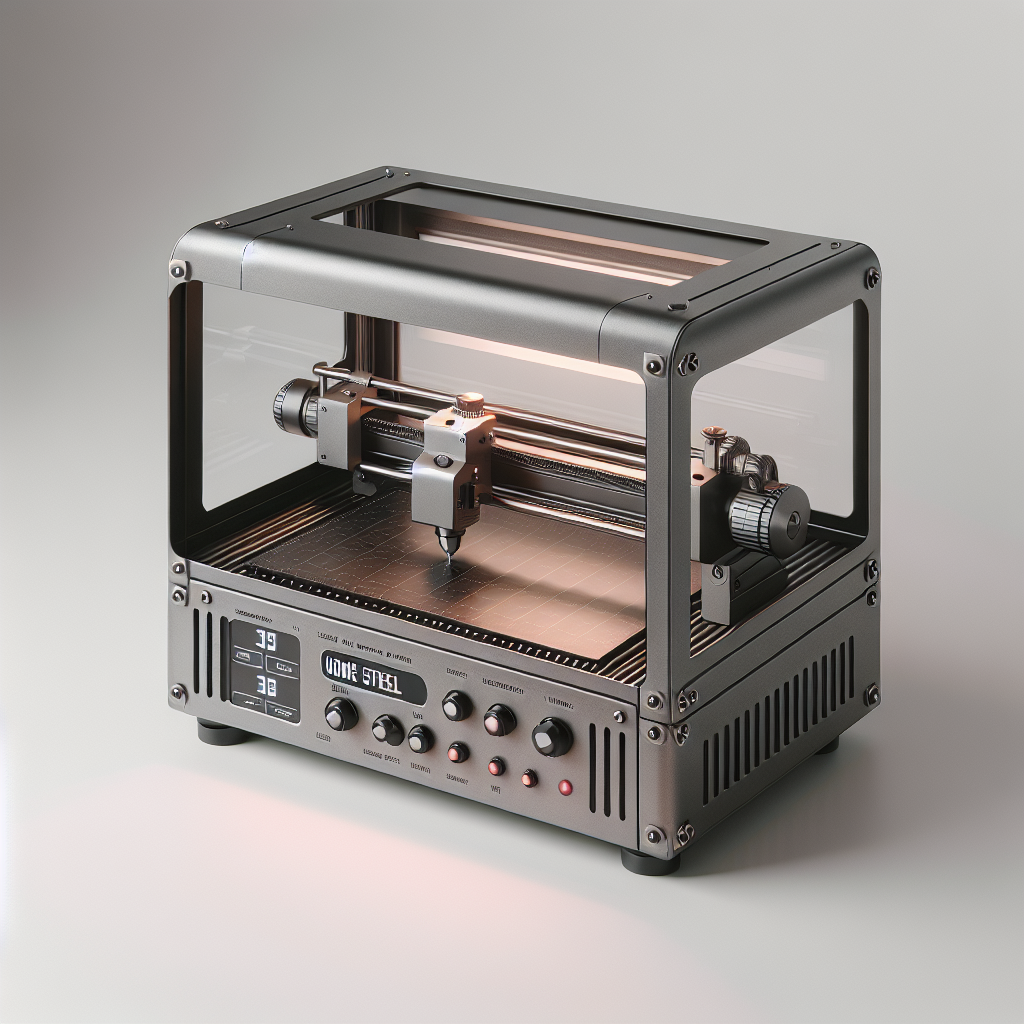

How to Choose the Right Laser Engraving Machine for Aluminium

Selecting the appropriate laser engraving machine is crucial for achieving optimal results when working with aluminium. Here are some factors to consider:

- Laser Wattage: Higher wattage lasers are generally better suited for thicker materials or darker engravings, while lower wattage machines are ideal for lighter work.

- Speed and Precision: Look for machines with adjustable settings to control the speed and intensity of the laser beam, ensuring precise engraving on aluminium surfaces.

- Software Compatibility: Ensure that the machine is compatible with popular design software like Adobe Illustrator or CorelDRAW for easy integration into your workflow.

- Budget: Consider your budget and the scale of your projects when choosing a laser engraving machine. Higher-end models often offer more advanced features, but there are cost-effective options available for smaller operations.

For those looking to invest in a reliable laser engraving machine, we recommend exploring , which provide excellent performance and value for money.

Advantages Over Traditional Engraving Methods

Laser engraving aluminium offers several advantages over traditional methods:

- No Physical Contact: Unlike mechanical engraving tools, lasers do not physically touch the material, reducing the risk of damage to delicate surfaces.

- Reduced Waste: The non-contact nature of laser engraving minimizes material waste, making it a more sustainable option.

- Ease of Use: Laser engraving machines are generally easier to operate and maintain compared to traditional engraving equipment.

Frequently Asked Questions About Laser Engraving Aluminium

Here are some common questions about laser engraving aluminium:

- Q: Can I engrave on any type of aluminium?

A: Yes, laser engraving works well with most types of aluminium. However, it’s important to test the material first to ensure optimal results. - Q: Does laser engraving damage the surface of the metal?

A: No, laser engraving is a non-contact process that minimizes surface damage. - Q: How long does it take to learn how to use a laser engraving machine?

A: With proper training and practice, most users can become proficient in operating a laser engraving machine within a few hours. - Q: Can I engrave multiple layers on the same piece of aluminium?

A: Yes, laser engraving allows for multi-layer engravings, creating depth and dimension in your designs.

Conclusion

Laser engraving aluminium is a game-changer for anyone looking to create precise, durable, and visually stunning engravings on metal surfaces. Its speed, precision, and versatility make it an ideal choice for a wide range of applications, from small-scale craft projects to large-scale industrial production. By investing in a high-quality laser engraving machine, you can unlock endless creative possibilities while improving efficiency and reducing costs.

If you’re ready to take the plunge into the world of laser engraving, be sure to check out for an excellent machine that combines performance, ease of use, and affordability. Happy engraving!