Laser Engraver Engraver Y Axis Moves to Which Direction: A Comprehensive Guide for Precision Enthusiasts

Understanding the Basics of Laser Engraving Mechanics

When working with advanced tools like the laser engraver engraver y axis moves to which direction, understanding directional movement is critical. The Y-axis, in particular, plays a pivotal role in achieving precise designs. Unlike traditional methods, laser engraving relies on coordinated movements across multiple axes to create intricate patterns. But which way does the Y-axis actually move? Let’s break this down.

The Role of the Y-Axis in Laser Engraving Systems

The Y-axis typically controls the vertical or horizontal movement of the laser head, depending on the machine’s configuration. For instance, in Cartesian systems, the Y-axis often moves forward and backward relative to the user’s perspective. This movement works in tandem with the X-axis (left-right) and Z-axis (up-down) to position the laser accurately. Why does this matter? Misalignment or incorrect calibration can lead to skewed designs, especially when engraving curved surfaces or fine details.

How the XTool Laser Engraver Optimizes Y-Axis Performance

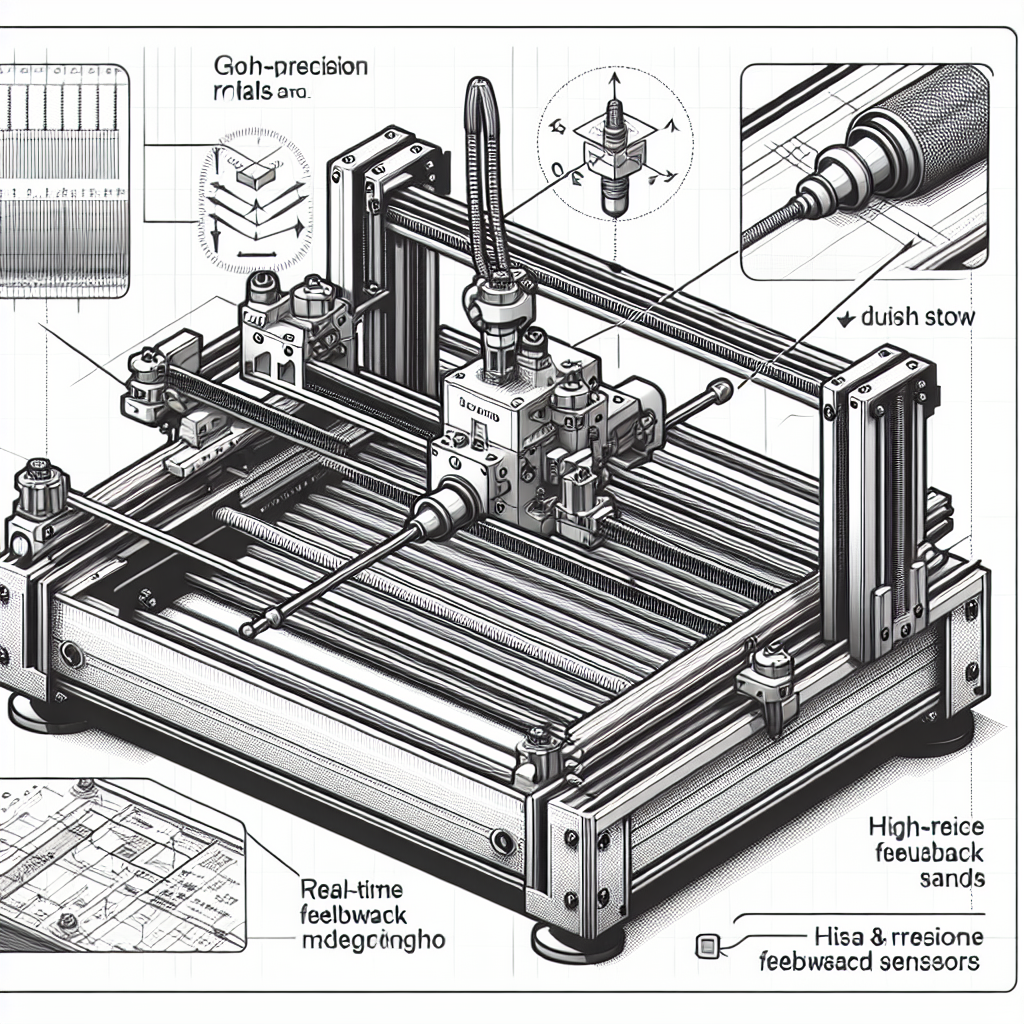

The laser engraver engraver y axis moves to which direction in the XTool Hawk F1 model is engineered for stability and speed. Its dual-motor system ensures smooth transitions, minimizing vibrations that could affect output quality. Key features include:

- High-precision rails for consistent Y-axis travel

- Real-time feedback sensors to correct deviations

- Adjustable speed settings for material-specific requirements

Did you know? Proper maintenance of the Y-axis components can extend the machine’s lifespan by up to 30%.

Applications in Custom E-Cigarette Design

For vaping enthusiasts, personalizing devices is a growing trend. The precision of a laser engraver engraver y axis moves to which direction enables intricate logos, textures, or even circuit patterns on e-cigarette casings. Whether you’re engraving stainless steel mods or acrylic panels, the Y-axis’s accuracy ensures crisp lines and repeatable results. Question: How do you test a laser engraver’s Y-axis alignment before working on expensive materials?

Common Challenges and Troubleshooting Tips

Even with advanced systems like the XTool Hawk F1, users may encounter issues such as:

- Uneven engraving depths due to Y-axis slippage

- Visible “stitching” errors between axis movements

- Delayed response during high-speed operations

Pro tip: Regularly clean the Y-axis rails and lubricate them with manufacturer-approved oils to prevent friction-related errors.

Future Innovations in Axis Control Technology

Emerging technologies like AI-driven predictive motion planning aim to revolutionize how laser engravers manage multi-axis coordination. Imagine a system where the Y-axis automatically adjusts its speed based on material density or design complexity. Such advancements could redefine customization possibilities for both industrial and hobbyist users.

Final Thoughts: Why Axis Direction Matters

Mastering the laser engraver engraver y axis moves to which direction isn’t just technical jargon—it’s the foundation of achieving professional-grade results. From e-cigarette customization to industrial prototyping, understanding this aspect ensures you harness the machine’s full potential. Ready to elevate your engraving projects? Start by mapping your design requirements to your laser engraver’s mechanical capabilities.

Have questions about optimizing Y-axis performance? Share them in the comments below!