The Ultimate Guide to Laser Cutter for Acrylic

Laser cutting technology has revolutionized industries by offering precision, efficiency, and versatility. Among the various applications of laser cutters, one stands out for its popularity and functionality: the laser cutter for acrylic. This article delves into everything you need to know about this innovative tool, including its benefits, uses, and how it compares to traditional methods. Whether you’re a hobbyist, a small business owner, or a professional artist, this guide will help you understand why a laser cutter for acrylic could be the perfect addition to your toolkit.

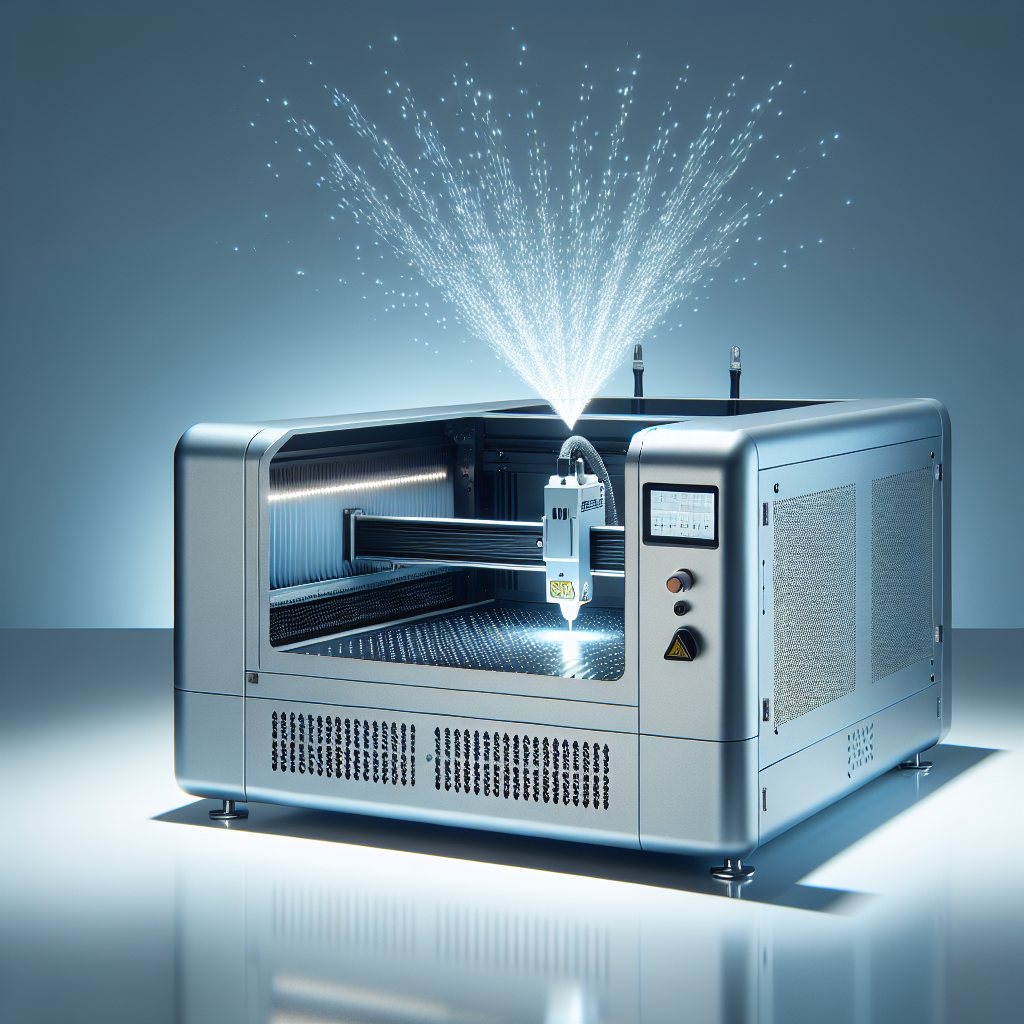

What is a Laser Cutter for Acrylic?

A laser cutter for acrylic is a machine designed specifically to cut and engrave acrylic materials with extreme precision. Unlike traditional cutting tools, which rely on mechanical blades or saws, laser cutters use a focused beam of light to melt, burn, or vaporize the material being cut. This results in cleaner edges, less waste, and greater design flexibility. The machine is equipped with a diode laser, which is known for its high efficiency and long lifespan.

The primary advantage of using a laser cutter for acrylic lies in its ability to handle intricate designs and complex patterns. Whether you’re creating signage, decorative items, or prototypes, this tool ensures that every cut is precise and professional-looking. Additionally, it can work with various other materials, including wood, plastic, leather, and fabric, making it a versatile addition to any workshop.

Why Choose a Laser Cutter for Acrylic?

There are several reasons why a laser cutter for acrylic is an excellent choice for both small-scale projects and large-scale production:

- Precision Cutting: The laser beam ensures that every cut is accurate, with minimal material waste.

- Speed: Compared to traditional cutting methods, laser cutting is faster and more efficient, saving you time and effort.

- Design Flexibility: You can create intricate designs and patterns that would be difficult or impossible to achieve with manual tools.

- Material Compatibility: While it excels at cutting acrylic, the machine is also compatible with a wide range of other materials.

- Cost-Effective: Over time, the savings from reduced material waste and faster production make this investment worthwhile.

If you’re wondering, “What can I do with a laser cutter for acrylic?” the answer is simple: almost anything! From creating custom signs to crafting decorative items, this machine opens up endless possibilities.

Applications of Laser Cutter for Acrylic

The versatility of a laser cutter for acrylic makes it suitable for a wide range of applications. Here are some common uses:

- Signage Production: Create custom signs, lettering, and logos with precision and style.

- Furniture Design: Cut intricate designs into furniture materials like plastic and wood.

- Jewelry Making: Engrave or cut delicate designs onto jewelry components.

- Prototype Development: Quickly create prototypes for testing before full-scale production.

- Decorative Items: Produce unique home decor, such as wall art, tableware, and more.

These applications highlight the laser cutter for acrylic‘s ability to handle both functional and creative projects. Whether you’re working on a small-scale craft or a large-scale production line, this machine is up to the task.

How Does a Laser Cutter for Acrylic Work?

Understanding how a laser cutter for acrylic works can help you make the most of its capabilities. Here’s a brief overview:

The machine uses a laser beam, which is generated by a diode laser. This beam is then focused through lenses onto the material being cut. The intense heat from the laser causes the material to melt, burn, or vaporize, creating a clean and precise cut. The machine operates under computer numerical control (CNC), meaning it follows pre-programmed designs or patterns stored in its software.

To achieve optimal results, it’s essential to set the correct settings for your material type and thickness. Factors such as laser power, speed, and focus distance will affect the quality of the cut. With practice and experimentation, you can master these settings to produce flawless cuts every time.

Benefits Over Traditional Cutting Methods

While traditional cutting methods like sawing or using mechanical blades have their place, they pale in comparison to a laser cutter for acrylic in several key areas:

- Clean Cuts: Laser cutting eliminates the risk of chipping or splintering that can occur with mechanical tools.

- Faster Production: The machine’s speed ensures that even large-scale projects are completed in a fraction of the time required by manual methods.

- Reduced Waste: By precisely following programmed designs, laser cutters minimize material waste and lower production costs.

- Design Complexity: Intricate patterns and designs that would be challenging or impossible to achieve manually are easily created with a laser cutter.

If you’re considering upgrading your workshop, the laser cutter for acrylic offers a compelling return on investment thanks to its efficiency, precision, and versatility.

Maintenance and Safety Tips

Like any machinery, proper maintenance is essential to ensure the longevity and optimal performance of your laser cutter for acrylic. Here are some tips to keep in mind:

- Cleanliness: Regularly clean the machine’s lenses and surfaces to prevent dust or debris from affecting performance.

- Lubrication: Follow the manufacturer’s instructions for lubricating moving parts to ensure smooth operation.

- Firmware Updates: Keep the machine’s software up-to-date to take advantage of new features and improvements.

- Safety Protocols: Always wear appropriate safety gear, such as goggles, when operating the machine. Ensure proper ventilation in your workspace to avoid inhaling fumes from the cutting process.

By following these tips, you can extend the life of your laser cutter for acrylic and ensure it continues to perform at its best for years to come.

Frequently Asked Questions About Laser Cutter for Acrylic

If you’re new to laser cutting, you may have several questions about how this technology works and what it can achieve. Here are answers to some of the most common questions:

- How much does a laser cutter for acrylic cost? Prices vary depending on the model and features, but you can find affordable options that provide excellent performance for small-scale projects.

- Can it cut through metal? While some high-powered lasers are capable of cutting metal, most laser cutters for acrylic are designed for non-metal materials like plastic, wood, and leather.

- Is it easy to learn how to use a laser cutter for acrylic? Yes, with the right training and practice, even beginners can master this technology. Many machines come with user-friendly software that simplifies the process.

If you’re still unsure about whether a laser cutter for acrylic is right for your needs, consider exploring reviews or reaching out to other users for firsthand insights.

Conclusion

The laser cutter for acrylic is an indispensable tool for anyone looking to combine precision, speed, and creativity in their projects. Its ability to handle a wide range of materials and produce intricate designs makes it a versatile addition to any workshop. Whether you’re a hobbyist or a professional, this machine offers unmatched potential for bringing your ideas to life.

If you’re ready to take the plunge into laser cutting technology, consider investing in a high-quality laser cutter for acrylic today. With proper care and technique, it will serve as a reliable companion for all your future projects!