The Diode Laser Cutter and Engraver: A Comprehensive Guide

Welcome to an in-depth exploration of the diode laser cutter and engraver, a versatile tool that has revolutionized the world of precision cutting and marking. Whether you’re a hobbyist, a small business owner, or a creative professional, this guide will provide you with all the information you need to understand how this innovative device works, its applications, benefits, and limitations. By the end of this article, you’ll have a clear understanding of why the diode laser cutter and engraver is becoming an essential tool for many enthusiasts and professionals alike.

What is a Diode Laser Cutter and Engraver?

A diode laser cutter and engraver is a compact, portable device designed to cut and engrave materials with precision. Unlike traditional cutting tools, it uses a focused beam of light generated by a diode laser to melt, burn, or vaporize the material being worked on. This process allows for intricate designs, patterns, and text to be etched into various surfaces with exceptional accuracy.

The device is often equipped with a built-in controller and software that enables users to create custom designs using computer-aided design (CAD) programs. The laser beam is directed by mirrors or lenses, ensuring precise control over the cutting or engraving process. This makes it ideal for both small-scale projects and professional applications.

One of the key features of a diode laser cutter and engraver is its ability to work with a wide range of materials, including wood, plastic, leather, fabric, and even some types of metal. This versatility makes it a valuable tool for crafters, makers, and businesses looking to customize products.

How Does It Work?

The diode laser cutter and engraver operates on the principle of converting electrical energy into light energy. The diode laser emits a high-intensity beam of light that is focused onto the material being cut or engraved. This concentrated beam generates heat, which either melts, burns, or vaporizes the material, creating precise cuts or engravings.

The device typically consists of several key components:

- Laser Diode: The source of the laser beam, which produces light at a specific wavelength.

- Focusing Lens: This lens concentrates the laser beam into a fine point to ensure precision in cutting and engraving.

- Mechanical System: Includes motors or actuators that move the laser head or workpiece, enabling accurate positioning for intricate designs.

- Software Interface: Allows users to design and control the laser operations through a computer or built-in interface.

The process begins with designing the desired pattern or text using software. This design is then converted into instructions for the laser cutter, which follows the programmed path to create the final product. The speed and intensity of the laser can be adjusted to suit different materials and project requirements.

Applications of a Diode Laser Cutter and Engraver

The diode laser cutter and engraver has a wide range of applications, making it a versatile tool for both personal and professional use. Here are some of the most common uses:

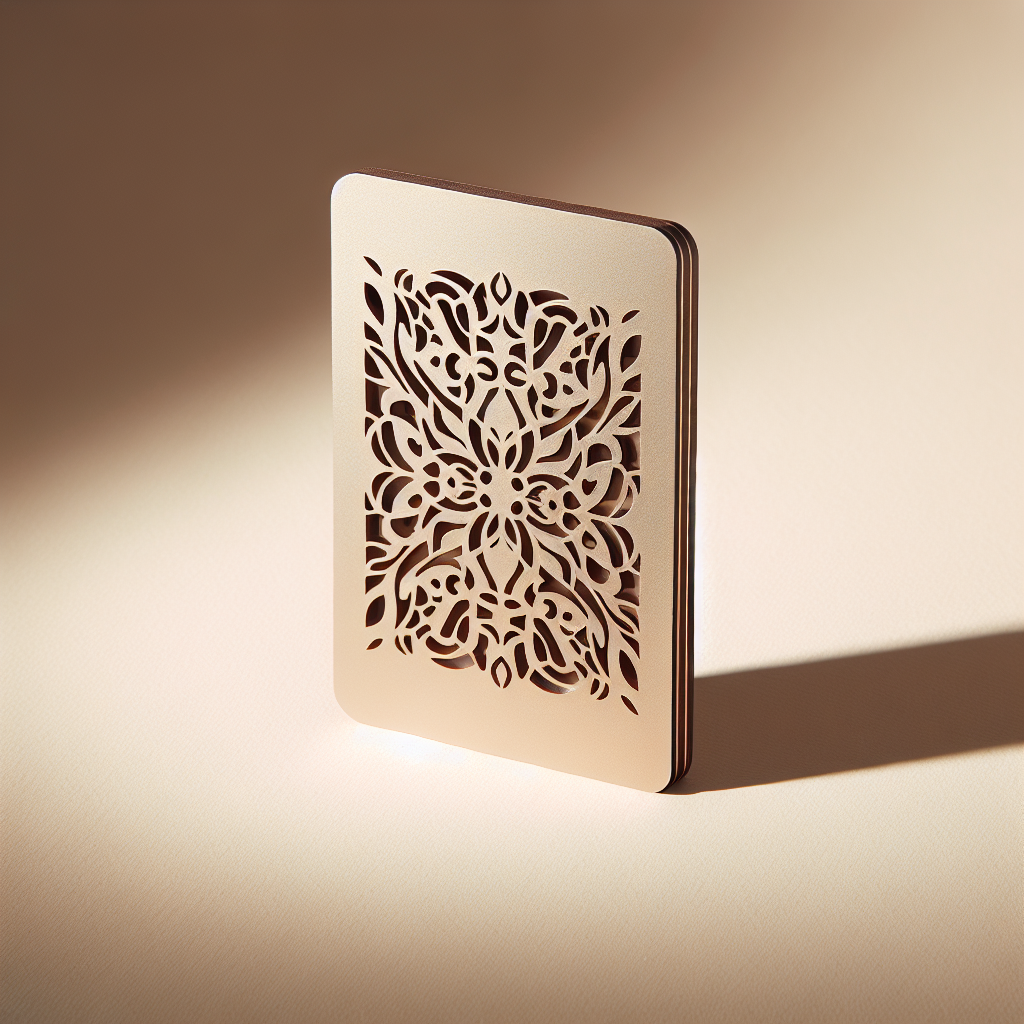

- Cutting Materials: Ideal for cutting shapes out of wood, plastic, leather, and other materials with precision.

- Engraving: Perfect for creating detailed designs, logos, or text on various surfaces.

- Prototyping:,。

- Jewelry Making:,、。

- Crafts and Artwork:、。

The ability to work with multiple materials makes the diode laser cutter and engraver an invaluable tool for hobbyists, crafters, and small businesses alike. It allows users to bring their creative visions to life with precision and ease.

Benefits of Using a Diode Laser Cutter and Engraver

There are several advantages to using a diode laser cutter and engraver over traditional cutting and engraving methods. Here are some of the key benefits:

- Precision and Accuracy: The focused laser beam ensures clean, precise cuts and engravings, even on intricate designs.

- Versatility: Compatible with a wide range of materials, making it suitable for various projects and industries.

- Speed: The laser cutting process is faster than manual methods, allowing for efficient production of custom items.

- Cost-Effective: Despite its high initial cost, the diode laser cutter and engraver can save money in the long run by reducing waste and minimizing the need for expensive tools or machinery.

- Ease of Use: Modern models come with user-friendly interfaces and software, making it easy to design and execute projects.

These benefits make the diode laser cutter and engraver a popular choice for those looking for a reliable and efficient cutting and engraving solution.

Limitations of a Diode Laser Cutter and Engraver

While the diode laser cutter and engraver offers many advantages, it also has some limitations that potential users should be aware of:

- Material Limitations: Certain materials, such as thick metals or highly reflective surfaces, may not be suitable for laser cutting due to the risk of damage or poor results.

- Initial Cost: The device can be expensive, especially high-end models with advanced features.

- Maintenance and Safety: Regular maintenance is required to ensure optimal performance, and proper safety precautions must be taken when handling the laser beam.

- Limited Cutting Depth: Compared to industrial-grade lasers, the diode laser cutter and engraver may have limitations in cutting depth and thickness of materials.

Understanding these limitations is essential for determining whether a diode laser cutter and engraver is the right tool for your specific needs.

Choosing the Right Diode Laser Cutter and Engraver

Selecting the appropriate diode laser cutter and engraver depends on several factors, including your project requirements, budget, and level of expertise. Here are some considerations to keep in mind:

- Budget: Determine how much you can afford to spend, as prices vary widely depending on the model and features.

- Project Needs: Consider the types of materials you’ll be working with and the complexity of your designs. Higher-powered lasers are better suited for thicker or tougher materials.

- Software Compatibility: Ensure that the device is compatible with the software you plan to use, such as CAD programs or laser-cutting-specific software.

- Size and Portability: If you need a compact and portable unit, look for models designed for smaller projects or personal use.

- Warranty and Support: Check the warranty period and customer support options in case of issues or technical difficulties.

By carefully evaluating these factors, you can choose a diode laser cutter and engraver that best fits your needs and budget.

Maintenance and Safety Tips

To ensure the longevity and safe operation of your diode laser cutter and engraver, it’s important to follow proper maintenance and safety procedures:

- Regular Cleaning: Keep the laser head, lenses, and other components clean to maintain optimal performance.

- Lubrication: Follow the manufacturer’s instructions for lubricating moving parts to prevent wear and tear.

- Safety Gear: Always wear appropriate safety gear, such as goggles or face shields, when operating the device.

- Ventilation: Ensure adequate ventilation when working with materials that produce fumes or particulates during cutting or engraving.

- Proper Handling: Avoid touching the laser beam or any heated components to prevent burns or injuries.

By adhering to these guidelines, you can maximize the lifespan of your diode laser cutter and engraver while ensuring a safe working environment.

Frequently Asked Questions (FAQs)

1. Is a diode laser cutter and engraver suitable for all materials?

No, certain materials may not be compatible with the device due to their reflective properties or thickness. Always check the manufacturer’s recommendations before cutting or engraving.

2. Can I use it for both cutting and engraving?

Yes, most models are designed to handle both tasks, allowing you to switch between modes depending on your project requirements.

3. How easy is it to learn how to use a diode laser cutter and engraver?

Modern devices often come with user-friendly interfaces and software, making them accessible even for beginners. However, some learning curve may be involved depending on the complexity of your projects.

4. What is the average lifespan of a diode laser cutter and engraver?

With proper maintenance, these devices can last several years. The exact lifespan depends on usage frequency, care, and the quality of the unit.

5. Are there any risks associated with using a diode laser cutter and engraver?

Yes, improper handling can lead to burns or injuries. Always follow safety guidelines and use protective gear when operating the device.

These FAQs address some common concerns about diode laser cutters and engravers, helping you make informed decisions and operate the device safely and effectively.

Conclusion

A diode laser cutter and engraver is a versatile and powerful tool that can greatly enhance your crafting, DIY projects, or small-scale manufacturing efforts. While it offers many benefits, such as precision, efficiency, and ease of use, it’s important to consider its limitations and safety requirements before making a purchase.

By understanding the features, advantages, and potential drawbacks of a diode laser cutter and engraver, you can determine whether it’s the right investment for your needs. With proper care and operation, this device can become an invaluable asset in your workshop or creative space.

If you’re ready to take your projects to the next level with precision cutting and engraving, a diode laser cutter and engraver might just be the tool you’ve been searching for. Happy crafting!

Diode Laser Cutter and Engraver: A Comprehensive Guide

A diode laser cutter and engraver is a versatile tool that combines precision cutting and engraving capabilities, making it ideal for various applications such as craft projects, sign-making, and industrial manufacturing.

Key Features:

– **Precision Cutting:** Capable of intricate designs with high accuracy.

– **Engraving Capability:** Suitable for detailed engravings on multiple materials.

– **User-Friendly:** Equipped with intuitive software for easy design uploads.

– **Versatility:** Works on a wide range of materials including wood, plastic, and metal.

Benefits:

– **Efficiency:** Quick setup and operation reduce project time.

– **Cost-Effective:** Reduces waste and minimizes tool costs over time.

– **Safety Features:** Includes safety measures to prevent accidents.

– **Compact Design:** Portable units for flexible use in different settings.

Applications:

– **Crafts and DIY Projects:** Ideal for creating custom designs on wood, fabric, or leather.

– **Signage and Decorations:** Efficiently cuts and engraves signs or decorative items.

– **Industrial Uses:** Utilized in prototyping and manufacturing for precise cuts.

Choosing the Right Model:

Consider factors like budget, project complexity, software compatibility, and portability when selecting a model. Higher-powered lasers are better for thicker materials.

Maintenance and Safety:

Regular cleaning, proper lubrication, and wearing safety gear ensure longevity and safe operation. Adequate ventilation is necessary when working with certain materials.

FAQs:

– **Compatibility:** Not all materials are suitable; check manufacturer guidelines.

– **Dual Use:** Most models handle both cutting and engraving.

– **Learning Curve:** User-friendly interfaces ease the learning process.

– **Lifespan:** With proper care, devices can last several years.

– **Safety Risks:** Proper handling and protective gear are essential.

Conclusion:

A **diode laser cutter and engraver** is a valuable tool for precision work. By understanding its features and requirements, you can determine if it’s the right investment for your projects. With careful use, it becomes an invaluable asset in any creative or manufacturing environment.

Whether you’re crafting, decorating, or manufacturing, a diode laser cutter and engraver could be the perfect tool to elevate your work.