Exploring the Capabilities of the 3D Printer and Laser Engraver

In recent years, technology has revolutionized the way we approach manufacturing, design, and creativity. Among the most exciting innovations is the combination of a 3D printer and a laser engraver, offering unparalleled precision, versatility, and efficiency. This article delves into the features, applications, and benefits of this cutting-edge tool, helping you understand how it can transform your projects.

What is a 3D Printer?

A 3D printer is a device that creates three-dimensional objects by layering materials based on a digital model. It has become a cornerstone in industries ranging from prototyping to manufacturing, enabling rapid production of complex geometries with high accuracy. The versatility of 3D printing lies in its ability to work with various materials, including plastics, metals, and even composites.

What is a Laser Engraver?

A laser engraver uses focused light beams to etch or cut intricate designs into surfaces. Unlike traditional methods, laser engraving offers exceptional precision and durability, making it ideal for creating detailed patterns on materials such as wood, metal, glass, and leather. The process is clean, efficient, and suitable for both small-scale and large-scale projects.

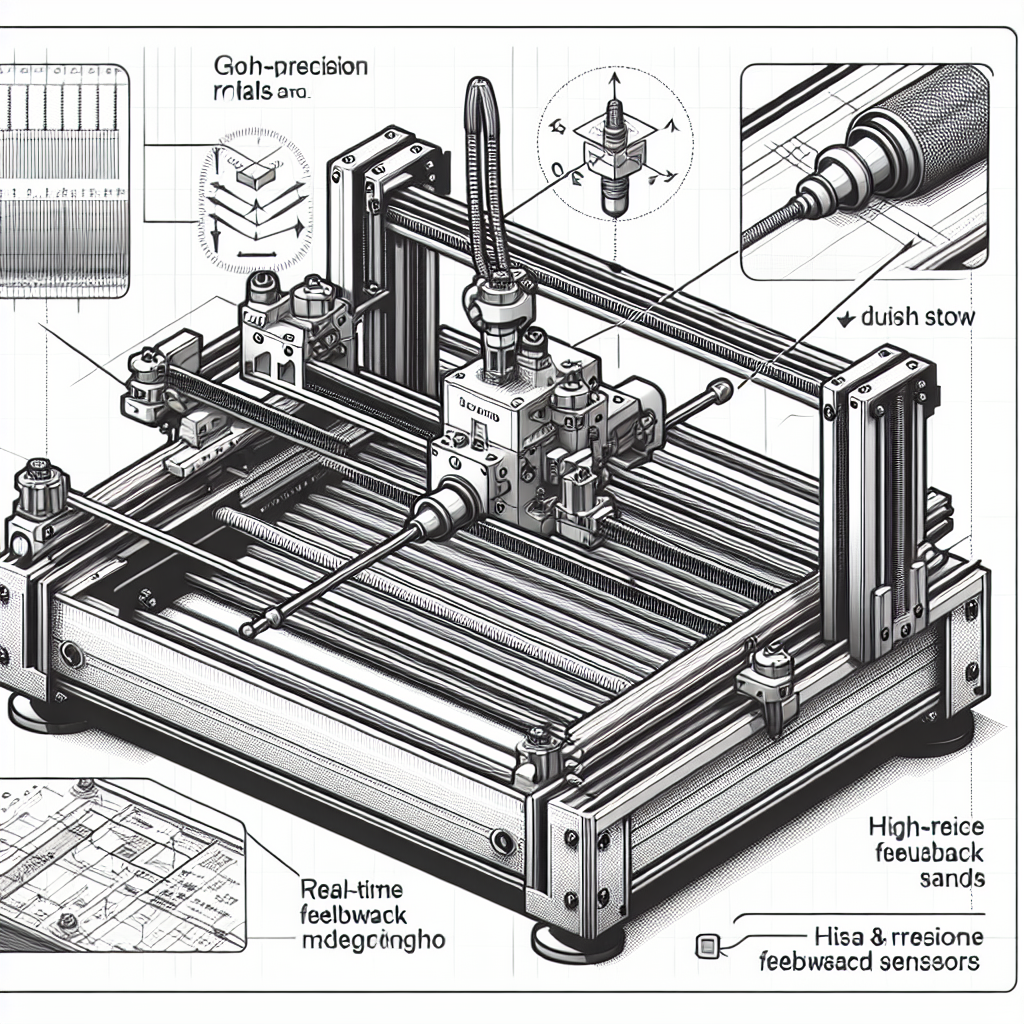

The Combination of 3D Printing and Laser Engraving

The integration of a 3D printer and a laser engraver creates a powerful tool that combines the strengths of both technologies. This hybrid system allows users to create complex, fully customized objects with intricate surface details in a single workflow. For example, you can print a 3D model and then immediately engrave it with text or patterns without transferring the object to another machine.

This fusion of technologies opens up endless possibilities for artists, designers, and manufacturers. Whether you’re creating personalized jewelry, architectural models, or industrial parts, this system provides the precision and flexibility needed to bring your vision to life.

Key Features of the 3D Printer and Laser Engraver

The 3D printer and laser engraver system comes with a range of features that make it stand out in the market. Some of its standout capabilities include:

- High Precision: Capable of producing intricate details with micron-level accuracy.

- Versatile Materials: Supports a wide range of materials, including plastics, metals, and composites for 3D printing, and wood, leather, and glass for laser engraving.

- User-Friendly Interface: Equipped with intuitive software that simplifies the design-to-production process.

- Efficiency: Reduces production time by combining two processes in one machine.

These features make it an ideal choice for both professionals and hobbyists looking to explore their creative potential.

Applications of the 3D Printer and Laser Engraver

The 3D printer and laser engraver system finds applications across various industries. Here are some key areas where it shines:

1. Customized Products

From personalized jewelry to custom phone cases, this system allows you to create unique items tailored to individual preferences. The ability to engrave intricate designs adds a personal touch that mass-produced goods often lack.

2. Prototyping and Manufacturing

Engineers and designers can use this system to quickly prototype products and test their functionality before full-scale production. Its precision ensures that prototypes closely resemble the final product, saving time and resources.

3. Art and Design

Artists can leverage the laser engraver to create stunning works on various materials. Whether it’s a detailed portrait on wood or an abstract pattern on metal, this system offers the flexibility to bring creative visions to life.

4. Industrial Applications

In industries like aerospace and automotive, the precision of this system is invaluable for creating lightweight yet durable components. The ability to engrave identification marks or serial numbers further enhances its utility in these sectors.

Benefits of Using a 3D Printer and Laser Engraver

Adopting a 3D printer and laser engraver system offers numerous benefits, making it a worthwhile investment for businesses and individuals alike. Some of the key advantages include:

1. Time-Saving

By combining two processes in one machine, this system significantly reduces production time. There’s no need to transfer objects between machines, minimizing delays and streamlining workflows.

2. Cost-Effective

While the initial investment may be substantial, the long-term savings are evident. Reduced material waste, faster production times, and lower labor costs contribute to a favorable return on investment.

3. Enhanced Creativity

The versatility of this system encourages experimentation and innovation. Users can explore new design possibilities and push the boundaries of what’s achievable in manufacturing and art.

Frequently Asked Questions

Before investing in a 3D printer and laser engraver, it’s essential to address common concerns:

1. What materials are compatible?

Most systems support a wide range of materials, including PLA, ABS, metals, wood, and leather. Always consult the manufacturer’s specifications to ensure compatibility with your project requirements.

2. How user-friendly is it?

Modern systems come with intuitive software that simplifies the design and printing process. Even those new to 3D printing can quickly learn to operate the machine with minimal training.

3. What are the maintenance requirements?

Like any precision tool, regular maintenance is necessary to ensure optimal performance. This includes cleaning the laser head, calibrating the system, and replacing worn-out parts as needed.

The Future of Manufacturing

The integration of a 3D printer and a laser engraver represents a significant leap forward in manufacturing technology. As advancements continue to unfold, we can expect even greater precision, faster production times, and expanded material compatibility.

For businesses looking to stay competitive or individuals seeking to explore their creative potential, this system offers an unparalleled opportunity to innovate and excel. With its versatility, efficiency, and precision, the 3D printer and laser engraver is poised to become a cornerstone of modern manufacturing and design.

Ready to take your projects to the next level? Explore the possibilities with this groundbreaking technology today!