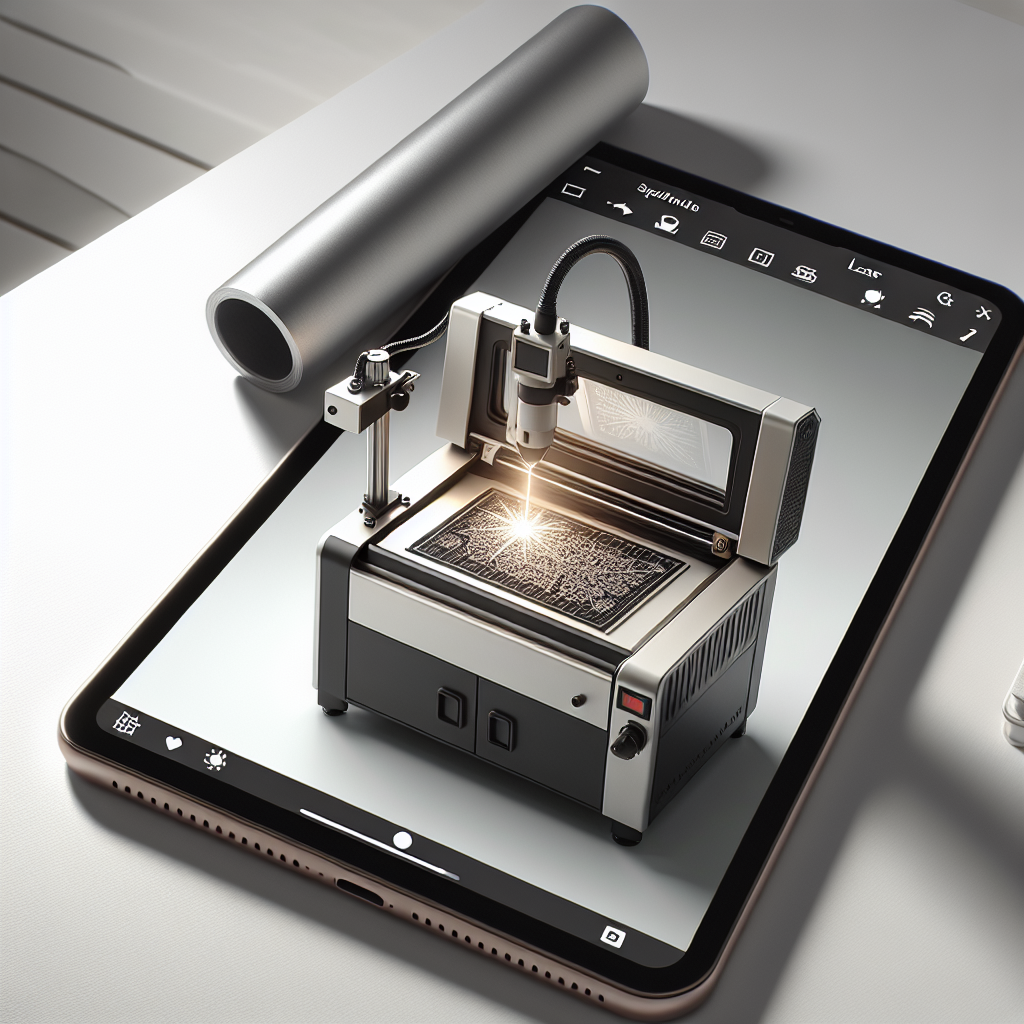

Metal CNC Laser Cutter: Precision Engraving Made Easy

In today’s fast-paced industrial world, precision and efficiency are paramount. The has emerged as a game-changer for businesses seeking to achieve intricate designs and high-quality engravings on metal surfaces. Whether you’re in the jewelry, automotive, or aerospace industry, this cutting-edge technology offers unparalleled versatility and precision. In this article, we’ll explore everything you need to know about the metal cnc laser cutter, its features, benefits, and how it can revolutionize your operations.

What is a Metal CNC Laser Cutter?

A metal CNC laser cutter is a advanced machine that uses a focused laser beam to cut or engrave intricate designs onto metal surfaces. Unlike traditional cutting methods, which often require multiple tools and setup times, the metal cnc laser cutter combines precision with speed, making it an ideal choice for both small-scale and large-scale production. The machine operates under CNC (Computer Numerical Control) technology, allowing users to program intricate designs and patterns directly into the system.

The process begins with a digital design file, which is uploaded into the CNC software. The software then translates this design into precise laser movements, ensuring that every cut or engraving is executed with micron-level accuracy. This level of precision makes it possible to create highly detailed designs that would be nearly impossible to achieve manually.

Key Features of a Metal CNC Laser Cutter

What sets the apart from other cutting tools? Let’s take a look at some of its key features:

- Precision Cutting: The machine uses a high-powered laser to cut through metal with extreme accuracy, ensuring clean and smooth edges.

- CNC Technology: With CNC control, users can program complex designs and patterns, allowing for consistent and repeatable results.

- Versatility: The machine supports a wide range of metal materials, including steel, stainless steel, aluminum, and more.

- High-Speed Processing: The laser beam operates at high speeds, making it suitable for both small-scale prototyping and large-scale production.

- User-Friendly Interface: Modern CNC laser cutters come with intuitive software that simplifies the design-to-production process.

These features make the an indispensable tool for businesses looking to stay competitive in today’s market.

Why Choose a Metal CNC Laser Cutter?

If you’re considering investing in a metal CNC laser cutter, you might be wondering what makes it worth the investment. Here are some compelling reasons:

- Cost-Effective: While the initial cost of purchasing a metal cnc laser cutter may seem high, the long-term savings from reduced material waste and increased efficiency make it a worthwhile investment.

- Improved Quality: The precision of the laser beam ensures that every cut or engraving is of the highest quality, reducing the need for post-processing and minimizing defects.

- Increased Productivity: With its high-speed processing capabilities, the machine can handle large volumes of work in a fraction of the time compared to traditional cutting methods.

- Creative Freedom: The ability to program intricate designs allows businesses to create unique and complex products that stand out in the market.

These benefits make the a versatile tool for businesses across various industries.

Applications of Metal CNC Laser Cutters

The versatility of the metal cnc laser cutter makes it suitable for a wide range of applications. Some common uses include:

- Jewelry Making: Creating intricate designs and engravings on precious metals like gold, silver, and platinum.

- Automotive Industry: Cutting and engraving parts for cars, trucks, and other vehicles.

- Aerospace: Producing lightweight and high-strength components for aircraft and spacecraft.

- Medical Devices: Manufacturing precision parts for medical instruments and devices.

- Signage: Engraving logos, text, and designs on metal signs and plaques.

These applications highlight the versatility of the and its ability to meet the demands of various industries.

Maintenance and Safety Considerations

While the metal cnc laser cutter is a powerful tool, proper maintenance and safety protocols are essential to ensure optimal performance and longevity. Some key considerations include:

- Regular Cleaning: The machine should be cleaned regularly to remove dust and debris that can interfere with its operation.

- Laser Beam Protection: Operators must wear appropriate protective gear, including goggles, to protect against laser exposure.

- Maintenance Checks: Regular inspections of the machine’s components, such as the laser lens and cooling system, are necessary to prevent malfunctions.

By following these maintenance and safety tips, businesses can maximize the lifespan and efficiency of their metal cnc laser cutter while ensuring a safe working environment for operators.

Conclusion

The is a cutting-edge tool that has revolutionized the way businesses approach metal cutting and engraving. With its precision, versatility, and high-speed processing capabilities, it offers an unmatched level of efficiency and quality. Whether you’re in the jewelry, automotive, or aerospace industry, investing in a metal cnc laser cutter can help you stay competitive and meet the demands of today’s fast-paced market.

If you’re ready to take your operations to the next level, consider exploring the options available for the . With its numerous benefits and applications, it’s a tool that can transform the way you work and help you achieve your business goals.