The Ultimate Guide to Laser Engraving Machine Wood: Enhancing Your Projects with Precision

Laser engraving machines have revolutionized the way we approach woodworking and design. Whether you’re a professional craftsman or a hobbyist looking to add a touch of elegance to your projects, a laser engraving machine wood is an indispensable tool. This article will explore the features, benefits, and applications of this cutting-edge technology, helping you decide if it’s the right choice for your needs.

What Is a Laser Engraving Machine Wood?

A laser engraving machine wood is a precision tool designed to etch intricate designs, patterns, or text onto wooden surfaces. Unlike traditional carving methods, which require manual skill and time, laser engraving offers unparalleled accuracy and efficiency. The machine uses a focused laser beam to remove material layer by layer, creating permanent and highly detailed engravings.

The process involves feeding the design into a computer, which then guides the laser to follow the pattern precisely. This makes it ideal for both small-scale projects, like engraving initials on a wooden spoon, and large-scale applications, such as creating decorative panels or signage.

Why Choose a Laser Engraving Machine Wood?

There are numerous reasons why a laser engraving machine wood is a worthwhile investment. Here are some of the key advantages:

- Precision and Accuracy: The laser beam ensures that every detail is captured with pinpoint accuracy, resulting in flawless engravings.

- Speed: Compared to manual carving, laser engraving is significantly faster, allowing you to complete projects in a fraction of the time.

- Versatility: Laser engraving machines can handle a wide range of materials, including wood, metal, and even glass, making them a versatile addition to any workshop.

- Customization: With digital design capabilities, you can create unique, custom patterns that are impossible to achieve manually.

- Durability: Laser engravings are permanent and resistant to wear, ensuring your projects retain their beauty over time.

If you’re wondering whether a laser engraving machine wood is right for you, consider the types of projects you undertake. Are you looking to add intricate details to furniture, create personalized gifts, or produce decorative items for resale? If so, this machine could be your new go-to tool.

How Does a Laser Engraving Machine Wood Work?

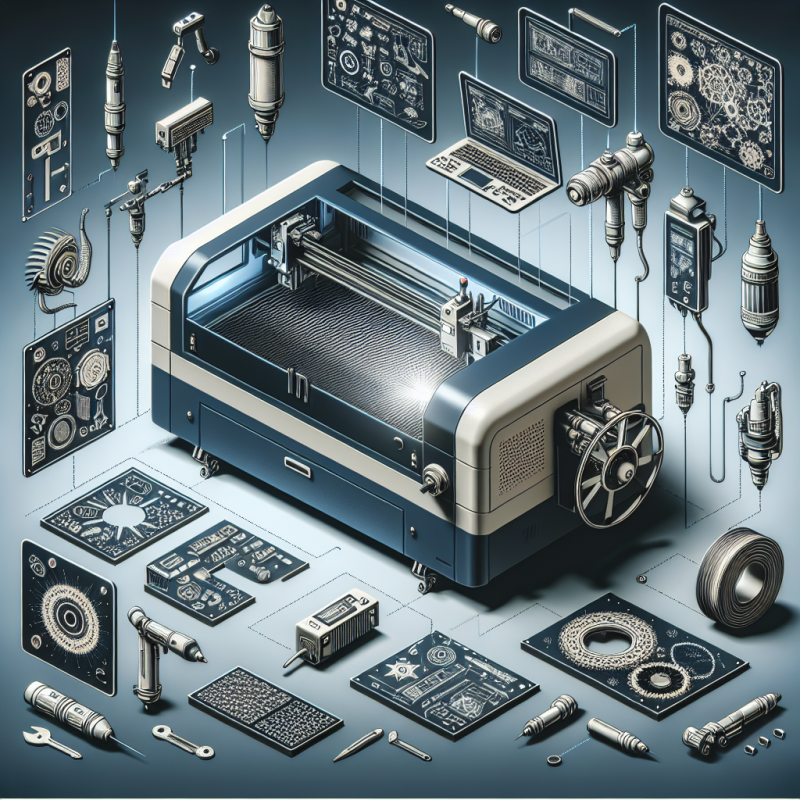

To understand how a laser engraving machine wood operates, let’s break down the process:

- Design Creation: You start by creating or selecting a design using computer-aided design (CAD) software. This design is then converted into a format compatible with the engraving machine.

- Material Setup: The wood is placed on the machine’s work surface, ensuring it is properly aligned and secured for precise engraving.

- Laser Engraving: The machine uses a laser beam to etch the design into the wood. The intensity and speed of the laser can be adjusted depending on the desired depth and detail.

- Post-Engraving: Once the engraving is complete, any excess material or residue is removed, and the final product is ready for use or further finishing.

This process not only saves time but also ensures consistency across multiple projects. Whether you’re working on a single piece or,。

Applications of Laser Engraving Machine Wood

Laser engraving machine wood has a wide range of applications, making it suitable for various industries and hobbies. Here are some common uses:

- Furniture Making: Add decorative elements or intricate patterns to tables, chairs, and cabinets.

- Custom Gifts: Create personalized engravings on items like wooden boxes, picture frames, and cutting boards.

- Signage: Produce professional-looking signs and plaques with sharp, readable text and designs.

- Crafts: Enhance your DIY projects by adding detailed engravings to items like jewelry boxes, decorative trays, and holiday ornaments.

- Restoration: Repair or restore damaged wooden surfaces with precise laser engraving to match the original design.

With its versatility, a laser engraving machine wood can be used in almost any woodworking project. Whether you’re working on a small-scale craft or a large-scale commercial application, this tool offers unmatched flexibility and precision.

Choosing the Right Laser Engraving Machine Wood

When selecting a laser engraving machine wood, there are several factors to consider:

- Power Output: Higher power lasers can handle thicker materials and deeper engravings, making them suitable for industrial applications. Lower-power machines are ideal for hobbyists or small-scale projects.

- Size and Build: Consider the size of your workspace and the types of projects you plan to undertake. Larger machines may offer more capacity but require more space.

- Software Compatibility: Ensure the machine is compatible with your existing design software or offers user-friendly tools for creating engravings.

- Budget: Laser engraving machines vary widely in price, so it’s important to find one that fits your budget while meeting your project requirements.

If you’re new to laser engraving, it may be helpful to start with a mid-range machine and upgrade as your skills and projects grow. This approach allows you to invest wisely while still enjoying the benefits of this innovative technology.

Maintenance and Safety Tips

Like any precision tool, a laser engraving machine wood requires proper care to ensure optimal performance and longevity. Here are some tips for maintaining your machine:

- Regular Cleaning: Dust and debris can accumulate on the machine’s surfaces and lenses, so clean them regularly to maintain accuracy and prevent damage.

- Lens Care: The laser lens is a critical component of the machine. Avoid touching it with your fingers or exposing it to harsh chemicals.

- Calibration: Periodically check and adjust the machine’s settings to ensure consistent engraving quality.

- Safety Precautions: Always wear protective eyewear when operating the machine, and keep your workspace well-ventilated to avoid inhaling dust particles.

By following these maintenance and safety tips, you can extend the life of your laser engraving machine wood and ensure safe, efficient operation for years to come.

Frequently Asked Questions About Laser Engraving Machine Wood

Before purchasing a laser engraving machine wood, you may have some questions. Here are answers to common inquiries:

- Q: Can I use the same machine for metal and wood?

A: Yes, many laser engraving machines are capable of handling multiple materials, including wood, metal, and glass. - Q: How easy is it to learn how to use a laser engraving machine?

A: Most machines come with user-friendly interfaces and software, making them accessible even for beginners. With some practice, you’ll be creating intricate designs in no time! - Q: What types of wood are best for laser engraving?

A: Hardwoods like oak, maple, and walnut are ideal for laser engraving due to their density and ability to hold fine details.

If you have more specific questions or need further guidance, consult the user manual or reach out to the manufacturer for support.

Final Thoughts

A laser engraving machine wood is a powerful tool that can elevate your woodworking projects to new heights. With its precision, versatility, and ease of use, it’s no wonder this technology has become so popular among craftsmen and hobbyists alike.

If you’re ready to take your woodworking skills to the next level, consider investing in a . Not only will it save you time and effort, but it will also allow you to create truly unique and stunning pieces that showcase your creativity and craftsmanship.

Whether you’re a seasoned professional or just starting out, a laser engraving machine wood is a tool worth considering. So why wait? Start exploring the possibilities today and unlock a world of artistic potential!