Exploring the Laser Cutter CNC: Features, Applications, and Benefits

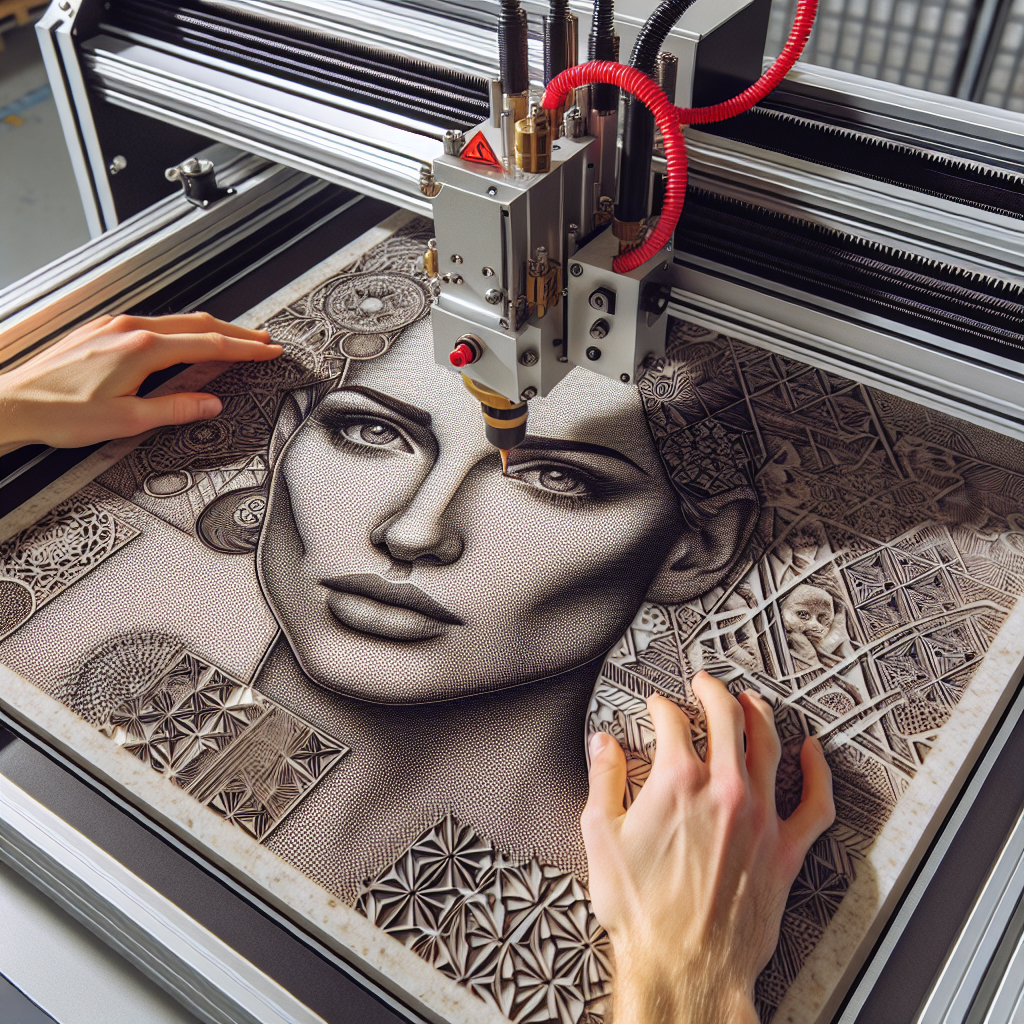

Have you ever wondered how modern industries achieve precise and intricate designs on metal surfaces? The answer lies in advanced technologies like the laser cutter cnc. This innovative machine has revolutionized engraving and cutting processes, offering unparalleled precision and efficiency. In this article, we’ll delve into the features, applications, and benefits of the laser cutter CNC, addressing common questions along the way.

The Basics: What is a Laser Cutter CNC?

A laser cutter CNC (Computer Numerical Control) machine uses laser technology to cut or engrave materials with exceptional accuracy. Unlike traditional methods, this machine relies on computer programming to guide the laser beam, ensuring precise and repeatable results. The system is highly versatile, capable of working with various materials, including metals, plastics, and composites.

One of the standout features of the laser cutter cnc is its ability to perform both cutting and engraving in a single setup. This dual functionality makes it an invaluable tool for industries ranging from manufacturing to custom craftsmanship. Whether you’re creating intricate designs or producing large-scale components, this machine delivers consistent performance.

Key Features of the Laser Cutter CNC

The laser cutter CNC is packed with features that make it a must-have for modern workshops. Here are some of its most notable attributes:

- Precision Engraving: The machine can achieve engraving details as fine as 0.1 mm, making it ideal for delicate designs.

- High-Speed Cutting: Equipped with a powerful laser source, the machine delivers fast cutting speeds while maintaining accuracy.

- User-Friendly Interface: The intuitive control panel allows even beginners to operate the machine with ease.

- Multi-Material Compatibility: It supports various materials, including steel, aluminum, and stainless steel, ensuring versatility in applications.

- Automatic Focus Adjustment: The laser beam automatically adjusts focus, ensuring consistent engraving quality across different surfaces.

Applications of the Laser Cutter CNC

The laser cutter cnc finds applications in a wide range of industries. Here are some common uses:

- Crafting Custom Jewelry: Create intricate designs on metals, ensuring each piece is unique and polished.

- Automotive Industry: Engrave or cut parts with precision, improving efficiency in production lines.

- Furniture Making: Add decorative elements to metal furniture components for a sleek finish.

- Signage Production: Generate high-quality engraved signs and plaques with sharp details.

- Prototyping: Quickly create prototypes with precise cuts, reducing development time and costs.

Advantages of Using a Laser Cutter CNC

Switching to a laser cutter CNC offers numerous benefits over traditional methods. Let’s explore some of them:

- Precision and Accuracy: The machine ensures consistent, high-quality results with minimal human error.

- Time Efficiency: Fast processing speeds reduce production time, allowing for quicker turnaround on projects.

- Cost-Effective: By minimizing material waste and reducing labor costs, the machine offers long-term savings.

- Versatility: Its ability to work with multiple materials and perform both cutting and engraving makes it a multi-functional tool.

Maintenance and Longevity

To ensure optimal performance, regular maintenance is essential. Here are some tips for maintaining your laser cutter CNC:

- Clean the Work Area: Keep the machine and work area free from dust and debris to prevent contamination.

- Inspect Laser Components: Regularly check the laser beam quality and alignment to maintain precision.

- Update Software: Stay current with software updates to enhance functionality and performance.

Frequently Asked Questions

1. Can I use this machine for non-metal materials?

Yes, while the laser cutter CNC excels at working with metals, it can also handle plastics and composites with appropriate settings.

2. How easy is it to learn to operate this machine?

The user-friendly interface makes it accessible even for those without prior experience in CNC machines.

3. What’s the maintenance schedule for optimal performance?

A routine check every few weeks, including cleaning and component inspections, ensures the machine runs smoothly.

Conclusion

The laser cutter cnc is a game-changer for industries seeking precision, efficiency, and versatility in their operations. With its advanced features and wide range of applications, it’s no wonder this machine has become a staple in modern workshops. Whether you’re a seasoned professional or just starting out, investing in a laser cutter CNC could be the key to unlocking new possibilities in your work.

If you have more questions or are considering purchasing one, reach out to experts for personalized advice. Happy crafting!