The Ultimate Guide to Metal Laser Cutting Machines

Laser technology has revolutionized various industries, offering precision, efficiency, and versatility in material processing. Among the many applications of laser technology, the metal laser cutting machine stands out as a game-changer for businesses that require intricate and high-precision cuts on metal materials. This article explores everything you need to know about metal laser cutting machines, their benefits, applications, and how they can transform your manufacturing processes.

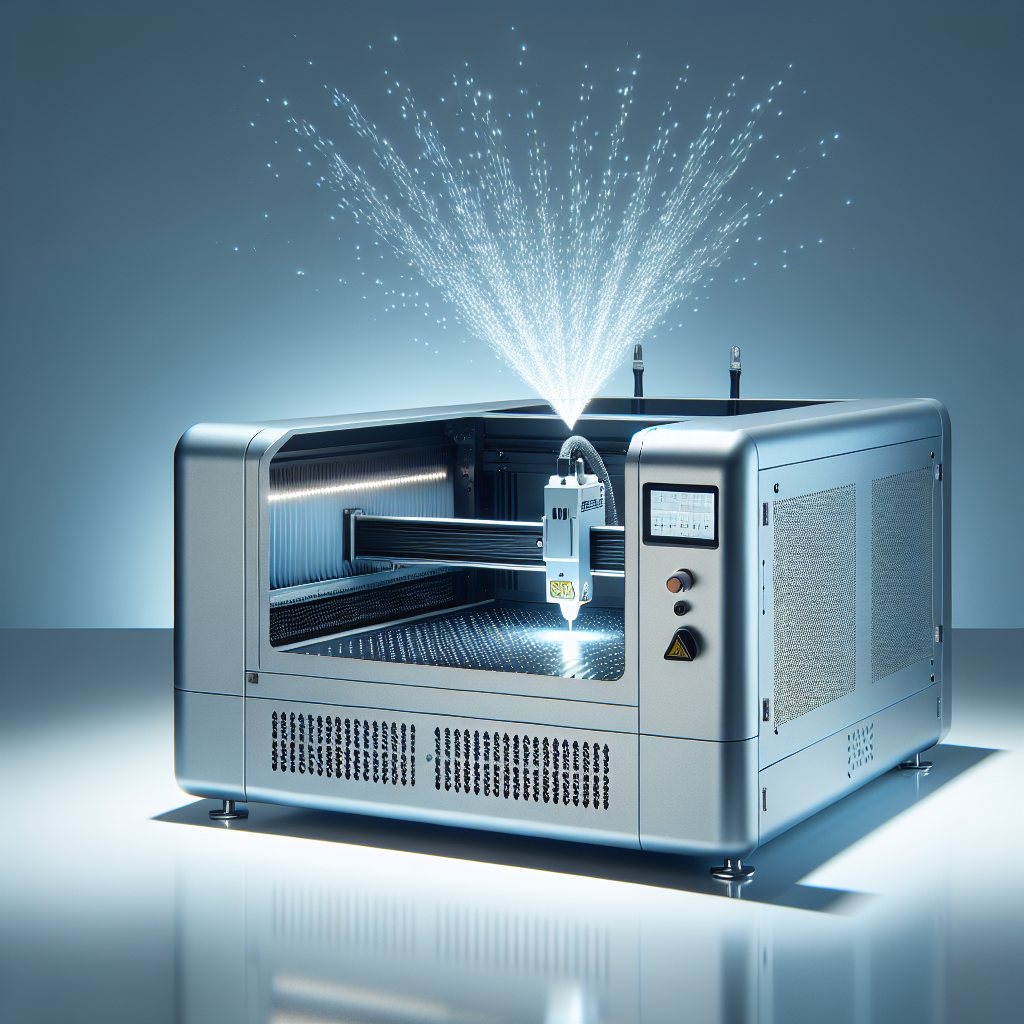

What is a Metal Laser Cutting Machine?

A metal laser cutting machine uses a focused laser beam to cut through various types of metal materials. Unlike traditional cutting methods, which rely on mechanical tools or plasma torches, laser cutting provides unparalleled accuracy and minimal material waste. The process involves directing the laser beam at high speeds over the material, melting, burning, or vaporizing it to create precise cuts.

The machine consists of several components, including a laser source, optics for focusing the laser beam, and a gantry system that moves the laser head across the material. Advanced software controls the cutting patterns, allowing for intricate designs and shapes that would be difficult or impossible to achieve with conventional tools.

Benefits of Using a Metal Laser Cutting Machine

Switching to a metal laser cutting machine offers numerous advantages over traditional cutting methods:

- Precision and Accuracy: The laser beam produces cuts with high precision, ensuring minimal kerf (the width of the cut) and tight tolerances. This is particularly important for industries requiring complex geometries or intricate designs.

- Speed: Laser cutting machines operate at high speeds, significantly reducing production time compared to manual or mechanical cutting methods.

- Versatility: These machines can cut through a wide range of materials, including steel, stainless steel, aluminum, and other metals. They are also capable of creating various shapes and patterns, making them suitable for diverse applications.

- Minimal Material Waste: The focused laser beam minimizes heat-affected zones (HAZ), reducing the risk of warping or damaging the material. This results in less waste and more efficient use of raw materials.

- Cost-Effectiveness: While the initial investment in a laser cutting machine may be high, the long-term savings from reduced material waste, faster production times, and lower labor costs make it a worthwhile investment.

Applications of Metal Laser Cutting Machines

Metal laser cutting machines are used across various industries for their precision and versatility. Some common applications include:

- Automotive Industry: Cutting metal parts such as engine components, chassis, and decorative elements with intricate designs.

- Architecture and Construction: Creating custom metal panels, structural beams, and ornamental details for buildings.

- Furniture Manufacturing: Cutting and engraving metal components for chairs, tables, and other furniture pieces.

- Jewelry Making: Precision cutting of precious metals like gold and silver to create intricate jewelry designs.

- Electronics: Cutting thin sheets of metal for circuit boards, enclosures, and other electronic components.

If you’re looking to enhance your manufacturing capabilities with a reliable and efficient cutting solution, consider investing in a metal laser cutting machine. These machines are ideal for businesses that require precision, versatility, and cost-effectiveness in their production processes.

Choosing the Right Metal Laser Cutting Machine

Selecting the right metal laser cutting machine depends on your specific needs, budget, and the type of materials you work with. Here are some factors to consider:

- Laser Power: Higher power lasers are suitable for thicker or harder metals, while lower power lasers are better for thin sheets or delicate materials.

- Cutting Speed: Determine the desired production rate and choose a machine that can meet your speed requirements without compromising on precision.

- Material Compatibility: Ensure the machine is capable of cutting the specific types of metal you work with, including thickness and hardness.

- Software and Controls: Look for machines with user-friendly software and advanced features like CNC (Computer Numerical Control) programming to create complex designs.

- Budget: Consider the initial cost of the machine, as well as ongoing costs such as maintenance, consumables, and training.

Future Trends in Metal Laser Cutting Technology

The field of laser cutting technology is continuously evolving, driven by advancements in materials science, software, and automation. Some emerging trends to watch for include:

- Increased Automation: Integration with robotic systems and AI algorithms for fully automated cutting processes.

- Higher Precision: Development of lasers with even smaller beam diameters, enabling cuts at an atomic level.

- Eco-Friendly Solutions: Adoption of more energy-efficient laser sources and waste reduction techniques to minimize environmental impact.

- Portability: Compact and mobile laser cutting machines for on-site applications and smaller-scale projects.

The metal laser cutting machine is a cornerstone of modern manufacturing, offering precision, versatility, and efficiency that traditional methods simply cannot match. Whether you’re working in automotive, construction, or another industry, investing in this technology can provide significant benefits for your business.

Frequently Asked Questions

1. How does a metal laser cutting machine work?

The machine uses a focused laser beam to melt, burn, or vaporize the material being cut. The laser is directed by advanced software that controls the cutting patterns and speeds.

2. What materials can a metal laser cutting machine handle?

Metal laser cutting machines are capable of cutting various types of metals, including steel, stainless steel, aluminum, copper, and precious metals like gold and silver.

3. Is a metal laser cutting machine suitable for small-scale projects?

Absolutely! Many manufacturers offer compact and affordable models designed for smaller workshops or hobbyists.

4. How much does a metal laser cutting machine cost?

The price varies depending on the size, power, and features of the machine. Entry-level models can start at around $10,000, while high-end industrial machines may cost hundreds of thousands of dollars.

5. Can I cut non-metal materials with a metal laser cutting machine?

Yes! Some models are also capable of cutting plastics, wood, and other non-metal materials, making them versatile tools for various applications.

Conclusion

The metal laser cutting machine is an indispensable tool for modern manufacturing, offering unparalleled precision, speed, and versatility. By upgrading to this advanced technology, businesses can enhance their production capabilities, reduce costs, and stay competitive in a rapidly evolving market. If you’re ready to take your manufacturing processes to the next level, it’s time to explore the benefits of investing in a metal laser cutting machine.

To learn more about specific models or find the perfect machine for your needs, check out .