Mastering Laser Engraving for Wood: Techniques, Benefits, and Applications

Laser engraving has revolutionized the way we personalize and decorate wooden surfaces. With its precision and versatility, laser engraving for wood has become a popular method for creating intricate designs, logos, and patterns on various wooden items. Whether you’re an artist, a craftsman, or a business owner looking to customize products, understanding how laser engraving works and its benefits can open up endless possibilities.

What is Laser Engraving for Wood?

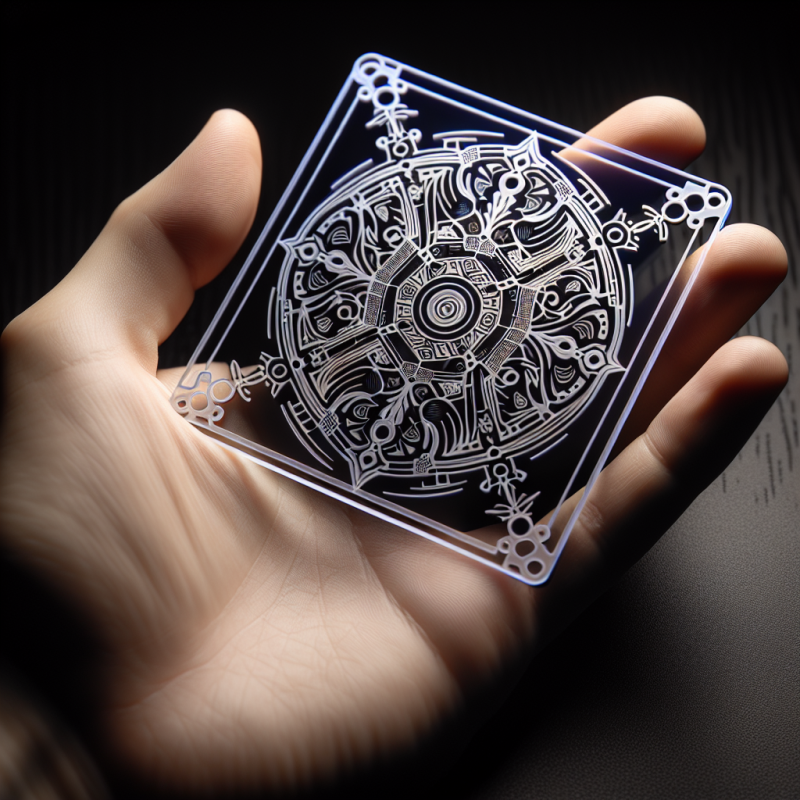

Laser engraving is a process that uses a focused beam of light (laser) to patterns or text onto surfaces. When it comes to wood, the laser beam interacts with the material by burning away tiny particles, creating permanent and detailed designs. Unlike traditional carving methods, laser engraving for wood offers unparalleled precision, speed, and consistency.

The process involves a machine equipped with a laser that emits high-energy light beams. These beams are directed at the wooden surface, removing layers of material to create the desired design. The depth of the engraving can be controlled by adjusting the laser’s power and speed, allowing for both shallow and deep engravings.

Advantages of Laser Engraving for Wood

There are numerous reasons why laser engraving for wood has become a favorite among craftsmen and businesses alike:

- Precision and Detail: Lasers can create intricate designs with unmatched accuracy, even on small surfaces.

- Speed and Efficiency: Compared to manual carving, laser engraving is much faster and more efficient, especially for large-scale projects.

- Versatility: Laser engravings can be applied to a wide range of wooden items, including furniture, decorative objects, and promotional materials.

- Durability: Engraved designs are permanent and resistant to wear and tear.

- Eco-Friendly: Laser engraving produces minimal waste and is a cleaner alternative to traditional carving methods.

Applications of Laser Engraving for Wood

The applications of laser engraving for wood are vast and varied. Here are some of the most common uses:

- Furniture Customization: Add personalized touches to tables, chairs, or cabinets with custom engravings.

- Decorative Items: Create unique wall art, picture frames, and other decorative pieces with intricate designs.

- Promotional Products: Businesses often use laser engraving to brand items like wooden tumblers, coasters, and gift boxes.

- Artistic Expression: Artists can use laser engraving to bring their creative visions to life on wood surfaces.

One of the most popular applications is laser engraving for tumblers. By personalizing wooden tumblers with names, logos, or motivational quotes, businesses and individuals alike can create memorable and functional promotional items. The precision of laser engraving ensures that even small details are captured perfectly, making each tumbler a unique piece.

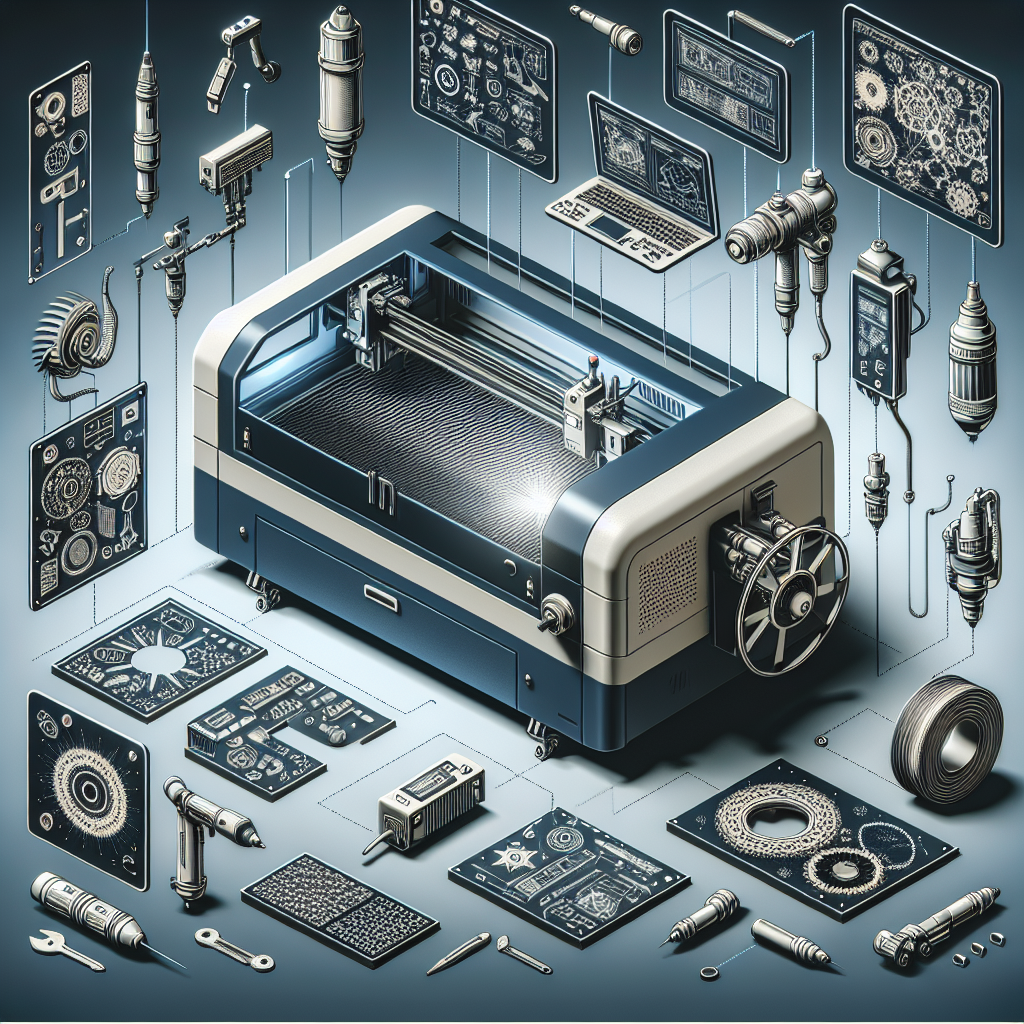

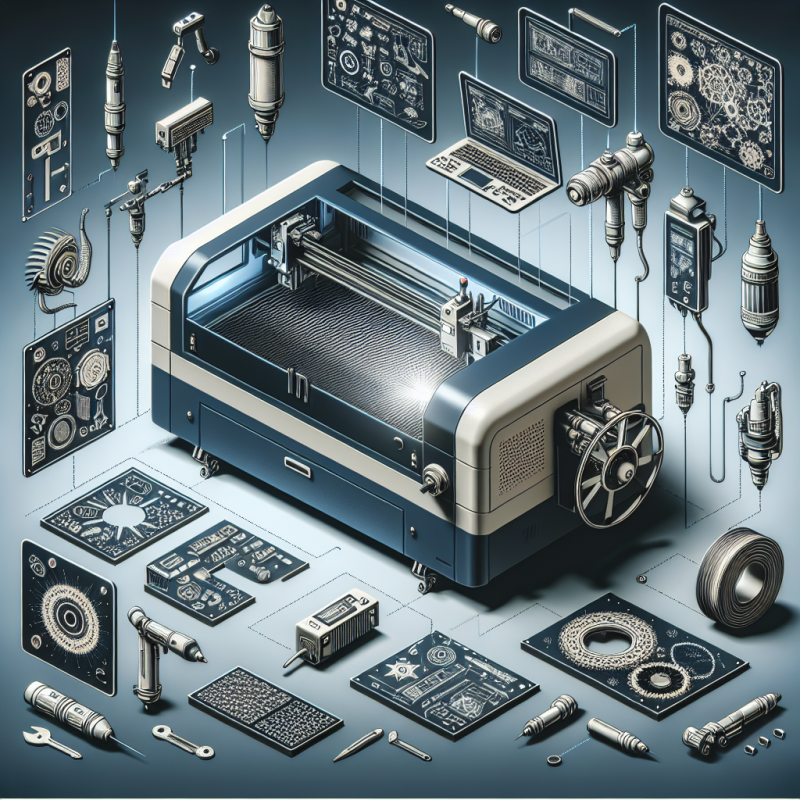

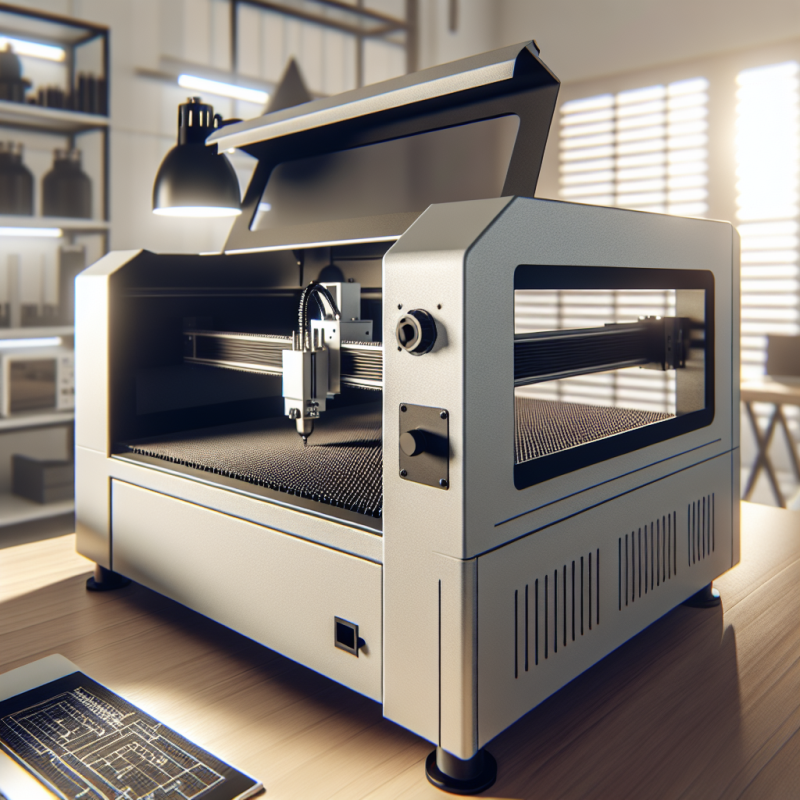

Choosing the Right Laser Engraving Equipment

To achieve professional-quality results with laser engraving for wood, you need the right equipment. A high-quality laser engraving machine is essential for ensuring precision and efficiency. When selecting a laser engraver, consider factors such as:

- Type of Laser: CO2 lasers are commonly used for wood engraving due to their ability to create deep, detailed engravings.

- Power Output: Higher power output allows for faster and deeper engraving but should be balanced with the type of material being engraved.

- Software Compatibility: Ensure the machine is compatible with design software that allows for easy creation and customization of engravings.

If you’re looking for a reliable laser engraving machine, consider checking out products like the [insert product name], which is designed specifically for wood engraving. This machine offers advanced features such as adjustable power settings, high-speed processing, and compatibility with various design software programs.

Maintenance Tips for Laser Engraving Machines

To ensure your laser engraving machine performs optimally for years to come, proper maintenance is essential. Here are some tips:

- Clean the Machine Regularly: Dust and debris can accumulate inside the machine, affecting its performance. Clean it after each use.

- Check Laser Alignment: Ensure the laser is properly aligned to maintain accurate engravings.

- Replace Worn Parts: Replace any worn or damaged components, such as lenses or mirrors, promptly.

The Future of Laser Engraving for Wood

As technology continues to evolve, so does the field of laser engraving. Innovations such as eco-friendly lasers and AI-driven design software are making laser engraving for wood more accessible and sustainable than ever before. Additionally, advancements in machine learning are enabling machines to adapt to different materials and designs automatically, further enhancing their versatility.

With its precision, efficiency, and versatility, laser engraving for wood is here to stay. Whether you’re a hobbyist, an artist, or a business owner, embracing this technology can take your projects to the next level. Start exploring the endless possibilities today with a reliable laser engraving machine like the [insert product name]!

If you’re ready to dive into the world of laser engraving for wood, check out our range of high-quality machines designed to meet all your needs. Visit [insert website link] to learn more and place your order today!