The Ultimate Guide to Balsa Wood Laser Cutters

Welcome to the fascinating world of precision craftsmanship with the balsa wood laser cutter. Whether you’re a hobbyist, an artist, or a professional craftsman, this innovative tool is revolutionizing how we work with balsa wood. In this comprehensive guide, we’ll explore everything you need to know about balsa wood laser cutters, including their benefits, applications, and how to choose the right one for your needs.

What is a Balsa Wood Laser Cutter?

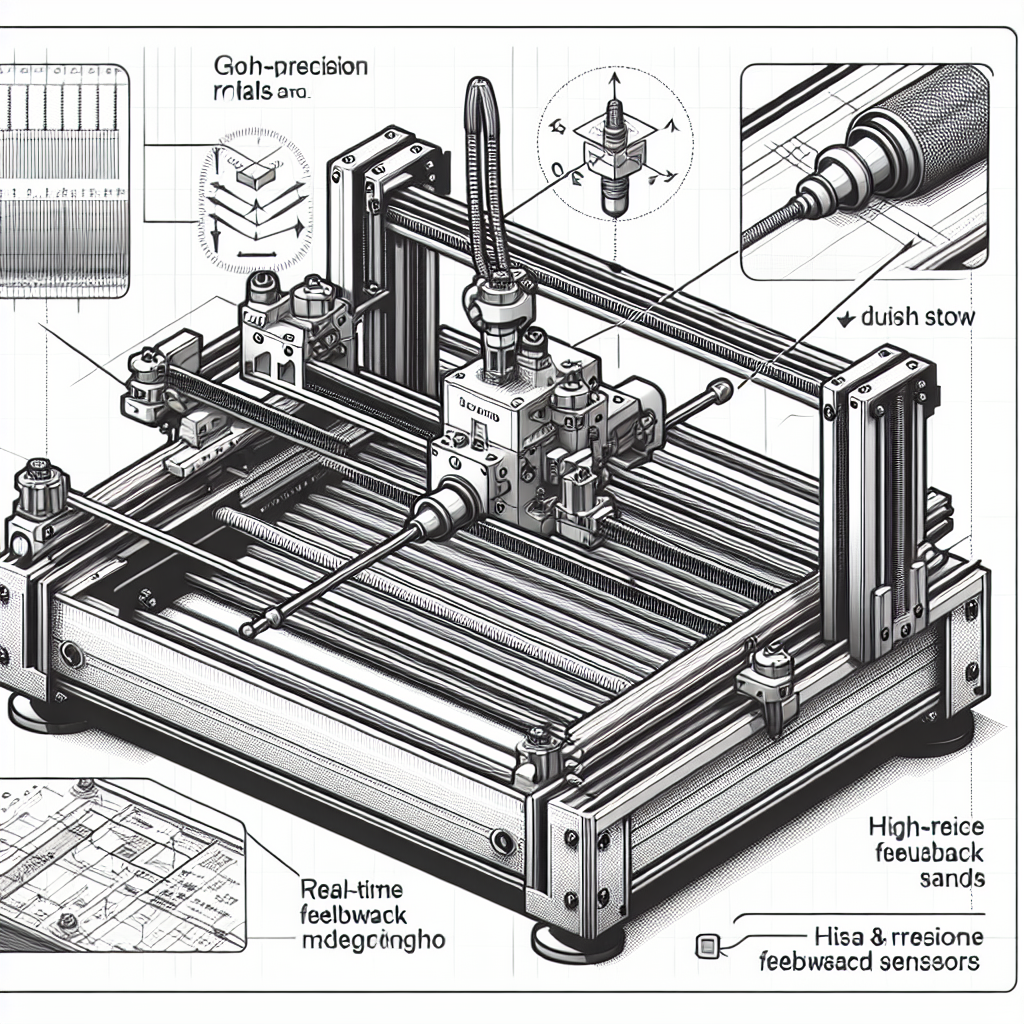

A balsa wood laser cutter is a machine that uses a focused beam of light to cut, engrave, or etch designs into balsa wood. Unlike traditional cutting tools, which rely on mechanical blades, laser cutters offer unparalleled precision and versatility. The process involves directing the laser beam at high speeds across the surface of the wood, vaporizing material as it goes. This results in clean, precise cuts with minimal material waste.

One of the key advantages of using a balsa wood laser cutter is its ability to handle intricate designs and patterns that would be difficult or impossible to achieve manually. Whether you’re creating scale models, decorative items, or prototypes, this tool provides the precision and efficiency needed to bring your vision to life.

Benefits of Using a Balsa Wood Laser Cutter

There are numerous benefits to using a balsa wood laser cutter, making it an indispensable tool for many applications. Let’s explore some of these advantages:

- Precision and Accuracy: The laser beam is incredibly precise, allowing you to create detailed designs with exact measurements.

- Speed: Laser cutting is much faster than traditional hand-cutting methods, saving you time and effort.

- Versatility: A balsa wood laser cutter can handle a wide range of materials, including different types of wood, plastics, and even some metals.

- Clean Cuts: The laser cutting process leaves behind smooth, polished edges with no splintering or rough surfaces.

- Cost-Effective: By minimizing material waste, laser cutters help reduce costs over time.

These benefits make the balsa wood laser cutter a valuable investment for anyone working with balsa wood. Is your current method of cutting and engraving holding you back? Consider upgrading to a laser cutter for a more efficient workflow.

Applications of Balsa Wood Laser Cutters

The applications of balsa wood laser cutters are vast and varied, making them suitable for both small-scale projects and large-scale production. Here are some common uses:

- Model Building: From airplanes to ships, balsa wood is a popular material for scale models due to its lightweight and strength-to-weight ratio. A laser cutter allows you to create intricate details with ease.

- Crafts and Artwork: Artists can use a balsa wood laser cutter to carve decorative items, signs, and custom designs.

- Prototyping: Engineers and designers often use balsa wood for creating prototypes due to its affordability and workability. A laser cutter speeds up the prototyping process significantly.

- Educational Tools: Laser cutters are used in schools and workshops to teach students about precision craftsmanship and design.

What projects have you always wanted to undertake but were held back by traditional cutting methods? A balsa wood laser cutter might just be the solution you’ve been looking for.

How to Choose the Right Balsa Wood Laser Cutter

If you’re considering purchasing a balsa wood laser cutter, there are several factors to keep in mind to ensure you choose the right machine for your needs. Here’s what you should look for:

- Laser Power: The power of the laser determines how thick and dense materials it can cut. For balsa wood, a lower-powered laser (e.g., 20-40 watts) is typically sufficient.

- Cutting Area: Consider the size of the projects you plan to work on. A larger cutting area allows for more versatility but may be unnecessary if your projects are small-scale.

- Build Quality: Look for a machine with sturdy construction and durable components. Cheaper models may seem appealing, but they often lack the precision and longevity of higher-quality machines.

- Software Compatibility: Ensure that the laser cutter is compatible with your design software. Most modern machines support popular programs like Adobe Illustrator and CorelDRAW.

- Customer Support: Choose a brand that offers good customer service and technical support in case you encounter any issues.

Are you ready to take your craftsmanship to the next level? Explore the options available and find the balsa wood laser cutter that best fits your needs. You can even check out this [link](https://example.com) for more information on specific models and features.

Maintenance and Safety Tips

Like any precision tool, a balsa wood laser cutter requires proper maintenance to ensure optimal performance and longevity. Here are some tips to keep your machine running smoothly:

- Clean Regularly: Dust and debris can accumulate inside the machine, affecting its performance. Clean the lens, mirrors, and other components regularly.

- Check Alignment: Misaligned optics can lead to uneven cuts or damage to the machine. Periodically check and adjust the alignment of the laser beam.

- Use Proper Ventilation: Laser cutting produces fumes and particulates, so ensure your workspace is well-ventilated or use a fume extraction system.

- Follow Safety Guidelines: Always wear protective eyewear when operating the machine. Keep flammable materials away from the work area to avoid fire hazards.

Do you have any tips for maintaining your laser cutter? Share them in the comments below!

Frequently Asked Questions

If you’re new to balsa wood laser cutters, you might have some questions. Here are answers to some of the most common ones:

- Can I use a laser cutter for other materials besides balsa wood? Yes, many laser cutters can handle a variety of materials, including plastics, acrylics, and even some metals.

- How easy is it to learn how to use a laser cutter? Most machines come with user-friendly interfaces, and there are plenty of tutorials available online to help you get started.

- What’s the cost of a balsa wood laser cutter? Prices vary depending on power, size, and features. You can find entry-level models for around $500-$1000, while high-end machines may cost several thousand dollars.

Do you have any other questions about balsa wood laser cutters? Feel free to ask in the comments!

Conclusion

The balsa wood laser cutter is a game-changer for anyone working with this versatile material. Its precision, speed, and versatility make it an invaluable tool for model builders, artists, engineers, and hobbyists alike. By choosing the right machine and maintaining it properly, you can unlock new creative possibilities and take your craftsmanship to the next level.

Are you ready to invest in a balsa wood laser cutter? With so many options available, there’s never been a better time to upgrade your tools and start creating amazing projects. Happy crafting!