The Ultimate Guide to Cutter Lasers: Enhancing Precision and Creativity

Laser technology has revolutionized numerous industries, from manufacturing to artistry. One of the most versatile tools in this field is the cutter laser, which combines precision with creativity to achieve remarkable results. If you’re curious about how cutter lasers work, their applications, and why they are becoming increasingly popular, this guide will provide you with all the information you need.

What is a Cutter Laser?

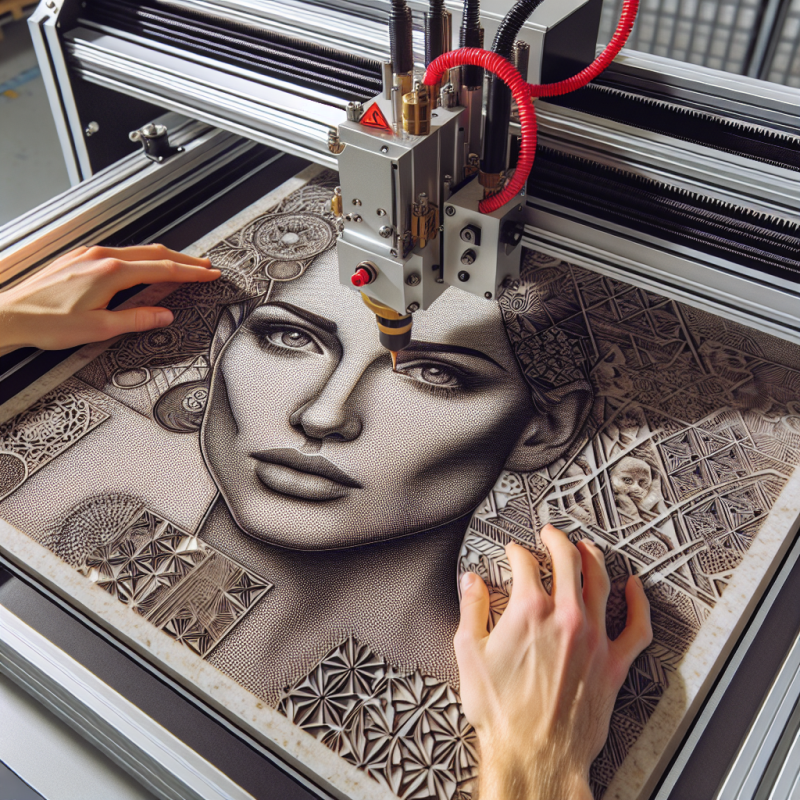

A cutter laser is a device that uses focused light energy to cut or engrave materials with extreme precision. Unlike traditional cutting tools, lasers offer unparalleled accuracy and versatility. They can work on various surfaces, including wood, metal, plastic, glass, and more. The cutter laser operates by directing a high-powered laser beam onto the material, which vaporizes or burns away the surface layer to create intricate designs or clean cuts.

One of the most popular applications of cutter lasers is in laser engraving and cutting for decorative purposes. For example, cutter laser systems are widely used to create personalized items like engraved tumblers, name plates, and custom jewelry. These devices are not only efficient but also environmentally friendly, as they produce minimal waste compared to traditional cutting methods.

Applications of Cutter Lasers

Cutter lasers have a wide range of applications across different industries. Here are some of the most common uses:

- Laser Engraving: Creating detailed designs on materials like wood, metal, and plastic.

- Cutting Shapes: Producing precise cuts for items such as furniture, signage, and decorative pieces.

- Etching: Adding text or patterns to surfaces without removing material, commonly used in glass etching.

- Prototyping: Quickly creating prototypes for products before full-scale production.

- Jewelry Making: Engraving intricate details on precious metals and stones.

These applications highlight the versatility of cutter lasers, making them an essential tool for both industrial and artistic purposes. Whether you’re working on a small-scale project or large-scale production, a cutter laser can adapt to your needs.

Benefits of Using a Cutter Laser

There are numerous reasons why cutter lasers have become so popular. Let’s explore some of the key benefits:

- Precision: Cutter lasers offer unparalleled accuracy, allowing for intricate designs and clean cuts.

- Versatility: They can work with a wide range of materials, making them suitable for various projects.

- Speed: Compared to traditional cutting methods, cutter lasers are much faster, saving time and increasing productivity.

- Minimal Waste: The focused laser beam ensures minimal material waste, reducing costs and environmental impact.

- Customization: Cutter lasers enable the creation of unique, personalized designs that are difficult to achieve with other tools.

These benefits make cutter lasers a valuable investment for businesses and hobbyists alike. If you’re looking to enhance your creativity or streamline your production process, a cutter laser could be the perfect solution.

How Does a Cutter Laser Work?

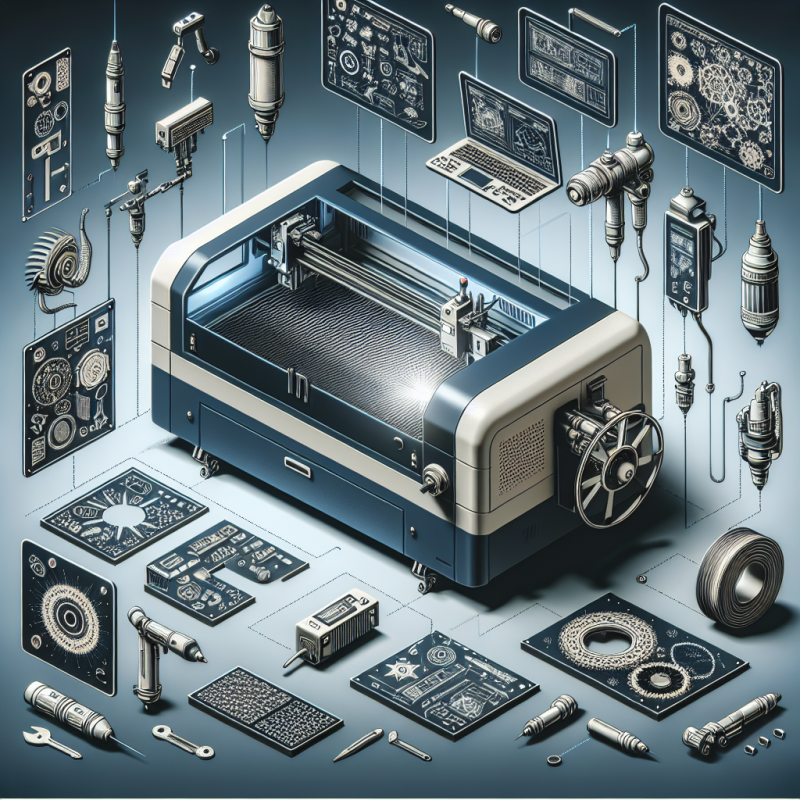

To fully understand the capabilities of a cutter laser, it’s essential to know how it works. The process involves several key components:

- Laser Source: Generates the focused beam of light energy.

- Focusing Lens: Concentrates the laser beam onto the material surface.

- Motion Control: Guides the laser beam to follow the desired cutting or engraving pattern.

- Cooling System: Ensures the laser operates efficiently without overheating.

The cutter laser works by directing the focused beam onto the material, which absorbs the energy and either melts, vaporizes, or burns away. This process is incredibly precise, allowing for intricate details to be engraved or cut with ease. The result is a clean, professional finish that is difficult to achieve with traditional tools.

Maintenance and Safety Tips

Like any precision tool, maintaining your cutter laser is crucial to ensure optimal performance and longevity. Here are some tips to keep in mind:

- Cleanliness: Regularly clean the lens and other components to prevent dust or debris from affecting accuracy.

- Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts to ensure smooth operation.

- Software Updates: Keep your cutter laser’s software up to date to access the latest features and improvements.

- Safety Precautions: Always wear protective eyewear when operating a cutter laser, and ensure proper ventilation in your workspace.

By following these maintenance and safety tips, you can extend the life of your cutter laser and continue producing high-quality results for years to come.

Frequently Asked Questions About Cutter Lasers

If you’re new to cutter lasers, you might have several questions. Here are some common ones:

- Can I use a cutter laser on all materials? While cutter lasers are versatile, they work best with certain materials like wood, metal, and plastic. Glass and stone can also be used but may require special settings or techniques.

- How easy is it to learn to use a cutter laser? Most cutter lasers come with user-friendly software that makes it easy to create designs and control the machine. With some practice, even beginners can produce professional-quality results.

- Are cutter lasers safe? Yes, as long as you follow proper safety precautions like wearing protective eyewear and ensuring good ventilation in your workspace.

If you have more specific questions, consulting the user manual or reaching out to the manufacturer can provide additional guidance.

Where to Buy a Cutter Laser?

If you’re interested in purchasing a cutter laser, there are several options available. Many online retailers and specialty stores offer a wide range of models to suit different needs and budgets. For example, cutter laser systems are widely available for both hobbyists and professionals.

When choosing a cutter laser, consider factors like the size of your projects, the types of materials you’ll be working with, and your budget. It’s also wise to read reviews and compare different models to find the best fit for your needs.

The Future of Cutter Lasers

As technology continues to advance, cutter lasers are likely to become even more sophisticated. Innovations in laser technology could lead to faster processing speeds, greater precision, and expanded applications. Additionally, advancements in software and automation may make cutter lasers even easier to use for both beginners and experienced users.

The future of cutter lasers looks bright, with potential applications in emerging fields like 3D printing and additive manufacturing. As these technologies evolve, cutter lasers will remain a cornerstone of precision cutting and engraving.

Conclusion

Cutter lasers are an incredible tool that combines precision, versatility, and efficiency to create stunning results. Whether you’re working on a small-scale project or running a large production line, a cutter laser can help you achieve your goals with ease. With proper maintenance and safety precautions, your cutter laser will serve you well for years to come.

If you’re ready to take the plunge into the world of laser cutting and engraving, consider purchasing a cutter laser today. It could be the perfect addition to your creative or production arsenal.