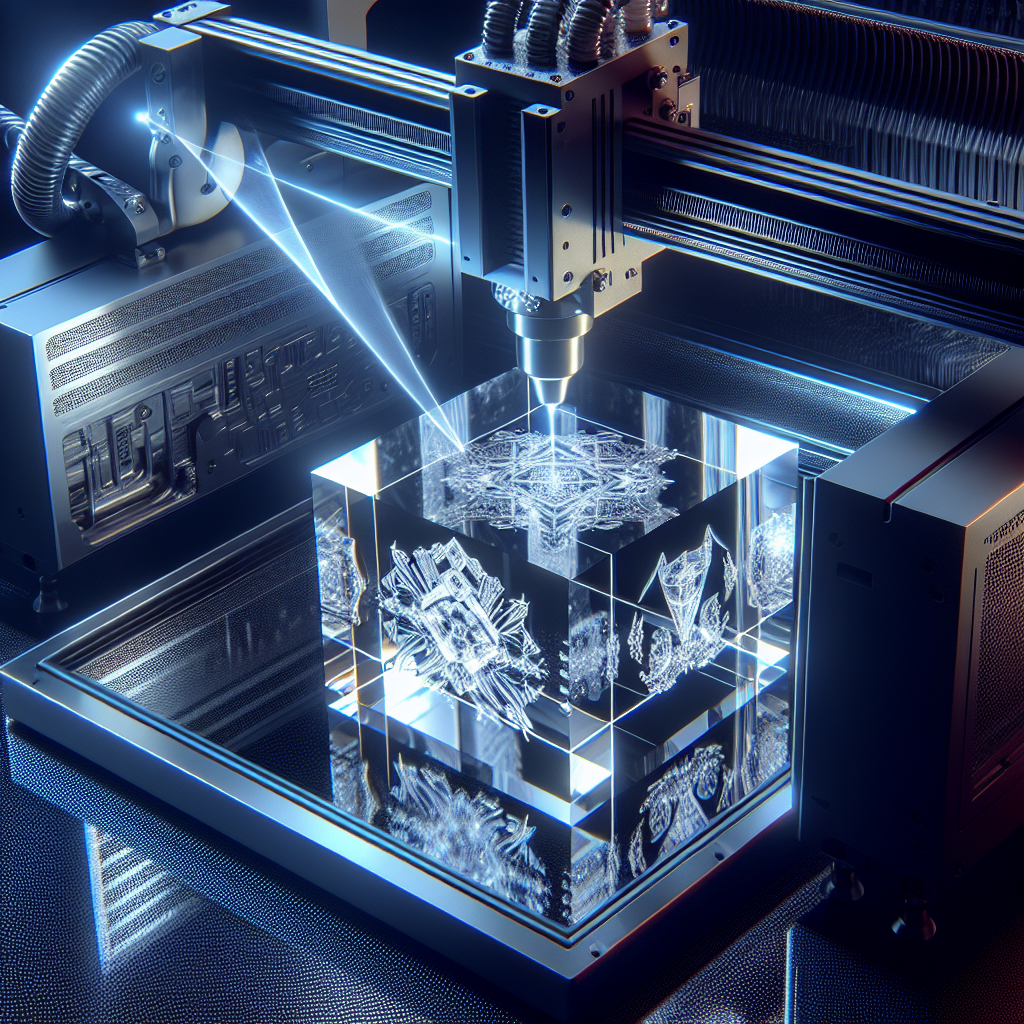

The Ultimate Guide to Laser Engraving on Glass

Laser engraving has become a revolutionary tool in the world of glass artistry and customization. Whether you’re creating personalized gifts, decorative items, or industrial applications, laser engraving on glass offers precision, durability, and a professional finish that traditional methods simply can’t match. In this comprehensive guide, we’ll explore everything you need to know about laser engraving on glass, from the tools you need to the creative possibilities it unlocks.

What is Laser Engraving?

Laser engraving is a process that uses high-powered lasers to etch or cut intricate designs into various materials, including glass. Unlike traditional engraving methods that rely on mechanical cutting tools, laser engraving offers unparalleled precision and versatility. The laser beam heats the surface of the glass, causing it to melt or vaporize, creating permanent marks without altering the structural integrity of the material.

The process is widely used in industries such as jewelry, home decor, automotive, and even medical devices, where precision and durability are critical. With the right equipment, like the laser engraver glass, you can create stunning designs that are both functional and aesthetically pleasing.

Benefits of Laser Engraving on Glass

Laser engraving on glass offers numerous advantages over traditional methods. Here are some of the key benefits:

- Precision and Detail: Lasers can etch intricate designs with pinpoint accuracy, making it ideal for complex patterns or text.

- Durability: Laser engravings on glass are permanent and resistant to fading or wear over time.

- Versatility: You can engrave almost any design, from simple logos to elaborate artwork, on various types of glass surfaces.

- Speed and Efficiency: Laser engraving is faster than traditional methods, making it suitable for large-scale production.

- Eco-Friendly: The process produces minimal waste and is energy-efficient compared to mechanical engraving.

These benefits make laser engraving a popular choice for both hobbyists and professionals alike. Whether you’re creating custom wedding favors or industrial components, the possibilities are endless.

Key Features of a Laser Engraver Glass Machine

Before investing in a laser engraver glass machine, it’s essential to understand its key features and how they contribute to the quality of your engravings. Here are some important aspects to consider:

- Laser Power: Higher power lasers can handle thicker materials and produce deeper engravings. However, for delicate glasswork, lower power settings may be more appropriate.

- Resolution: The resolution of the laser determines the level of detail in your designs. Higher resolutions are ideal for intricate patterns and text.

- Software Compatibility: Most laser engravers come with user-friendly software that allows you to design and preview your engravings before cutting.

- Motion Control: Precision in motion control ensures accurate and consistent engravings, even over large surfaces.

- Safety Features: Look for machines with built-in safety features like emergency stop buttons and enclosed laser chambers to protect users from potential hazards.

When choosing a laser engraver glass machine, it’s important to consider your specific needs. For example, if you’re working on small-scale projects, a desktop model may suffice, while larger operations may require industrial-grade equipment. The laser engraver glass offers a perfect balance of power, precision, and versatility for most applications.

Applications of Laser Engraving on Glass

Laser engraving on glass is incredibly versatile and can be applied to a wide range of projects. Here are some common uses:

- Custom Decorations: Engrave family names, dates, or meaningful quotes onto glassware like vases, wine glasses, or picture frames.

- Jewelry Making: Create personalized pendants, charms, and other accessories with intricate designs.

- Industrial Applications: Engrave serial numbers, barcodes, or logos onto glass components for identification purposes.

- Crafts and Art: Use laser engraving to create unique pieces of art, such as stained glass windows or decorative tiles.

- Medical Devices: Engrave precise markings on glass vials, test tubes, and other laboratory equipment.

These applications highlight the versatility of laser engraving on glass. Whether you’re working on a small-scale project or an industrial application, there’s no limit to what you can create with this innovative technology.

Tips for Successful Laser Engraving on Glass

To achieve the best results when laser engraving on glass, it’s important to follow some basic guidelines. Here are a few tips to keep in mind:

- Material Preparation: Clean the glass surface thoroughly before engraving to ensure optimal adhesion and visibility of the design.

- Test Your Settings: Before starting your project, perform a test run on scrap glass to fine-tune your laser settings and ensure the desired depth and clarity.

- Use Proper Protective Gear: Always wear safety goggles and other protective equipment when operating a laser engraver machine.

- Design Considerations: Keep your designs simple for beginners, as overly complex patterns can be challenging to execute without practice.

- Maintenance: Regularly clean and maintain your laser engraver glass machine to ensure it runs smoothly and produces high-quality engravings.

By following these tips, you’ll be able to create professional-looking engravings that enhance the beauty and functionality of your glass projects.

Frequently Asked Questions

If you’re new to laser engraving on glass, here are some answers to common questions:

- Can I use any type of glass with a laser engraver? While most types of glass can be engraved, some materials may require different settings or precautions. Always consult your machine’s user manual for specific recommendations.

- Is laser engraving on glass permanent? Yes, laser engravings are permanent and resistant to fading or wear over time.

- Can I remove a laser engraving from glass? Unfortunately, once engraved, the design cannot be easily removed. Always double-check your designs before engraving.

- How long does it take to learn laser engraving on glass? With practice and the right equipment, you can start creating basic engravings in just a few hours. Mastering more complex techniques may take longer.

If you’re still unsure about anything, don’t hesitate to reach out to experienced users or consult online forums for additional advice and support.

Conclusion

Laser engraving on glass is a powerful tool that opens up a world of creative possibilities. Whether you’re looking to create custom decorations, industrial components, or unique works of art, the laser engraver glass is an excellent choice for achieving professional results. With its precision, versatility, and ease of use, this technology is sure to elevate your projects to new heights.

So why wait? Start exploring the endless possibilities of laser engraving on glass today and bring your creative visions to life!